Maple Systems 5000HD Series User Manual

Page 112

106

EZwarePlus Programming Manual

1010-1015, Rev. 03

Ethernet/COM port: Select whether the remote HMI will be connected using Ethernet or a serial

COM port. You must use the Master-Slave Server protocol when COM port is selected.

IP Address: Enter the IP address of the remote HMI.

Port No.: Enter the TCP/IP port assigned to the remote HMI during its configuration (default is 8000).

Click OK.

4. Click the PLC type drop-down box and select the appropriate driver for your PLC type.

5. There are five selections for PLC I/F:

RS-232 /RS-485 2W / RS-485 4W / Ethernet / USB

Choose the PLC interface appropriate for your PLC model.

6. Select the PLC station number for your PLC if appropriate (see Controller information Sheet for your

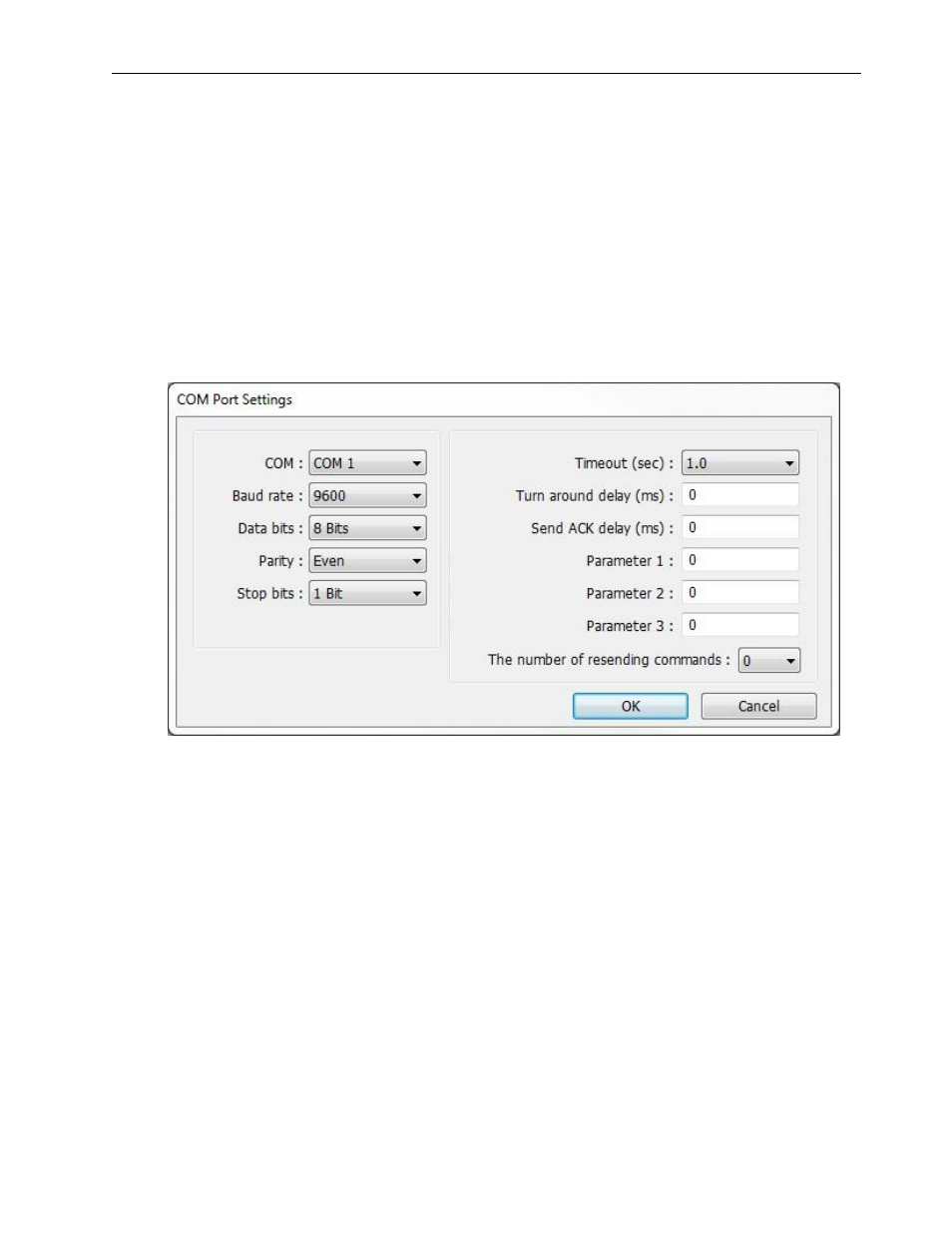

PLC) and then click Settings… The COM Port Settings dialog appears.

7. Select the appropriate COM port. This is the COM port used by the HMI.

8. Select Baud rate, Data bits, Parity and Stop bits. Use Maple Systems’ Controller Information Sheets

or the PLC manufacturer’s operations manual for information on the communications parameters

required by the PLC. These parameters must match the PLC settings.

Timeout adjusts the amount of time (in seconds) it takes for the PLC no response message to popup

when communication is lost or disrupted between the HMI and PLC.

Turn around delay adjusts the amount of time (in milliseconds) that the HMI waits after receiving a

reply before sending the next request.

Send ACK delay and the Parameter 1-3 settings are optional depending on the PLC type. Refer to the

Controller Information Sheet for the PLC selected.

9. The number of resending commands sets the maximum number of retries the HMI will attempt to

establish communication when communication is lost. When “0” is selected, the HMI will continue to

retry indefinitely.

10. Click OK.

11. PLC default station no.: Defines the station number or unit ID number of the PLC, if applicable (e.g.,

Modbus station number).