Tolerance defaults setup – Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 90

0433-INS-400 Rev. E

6-44

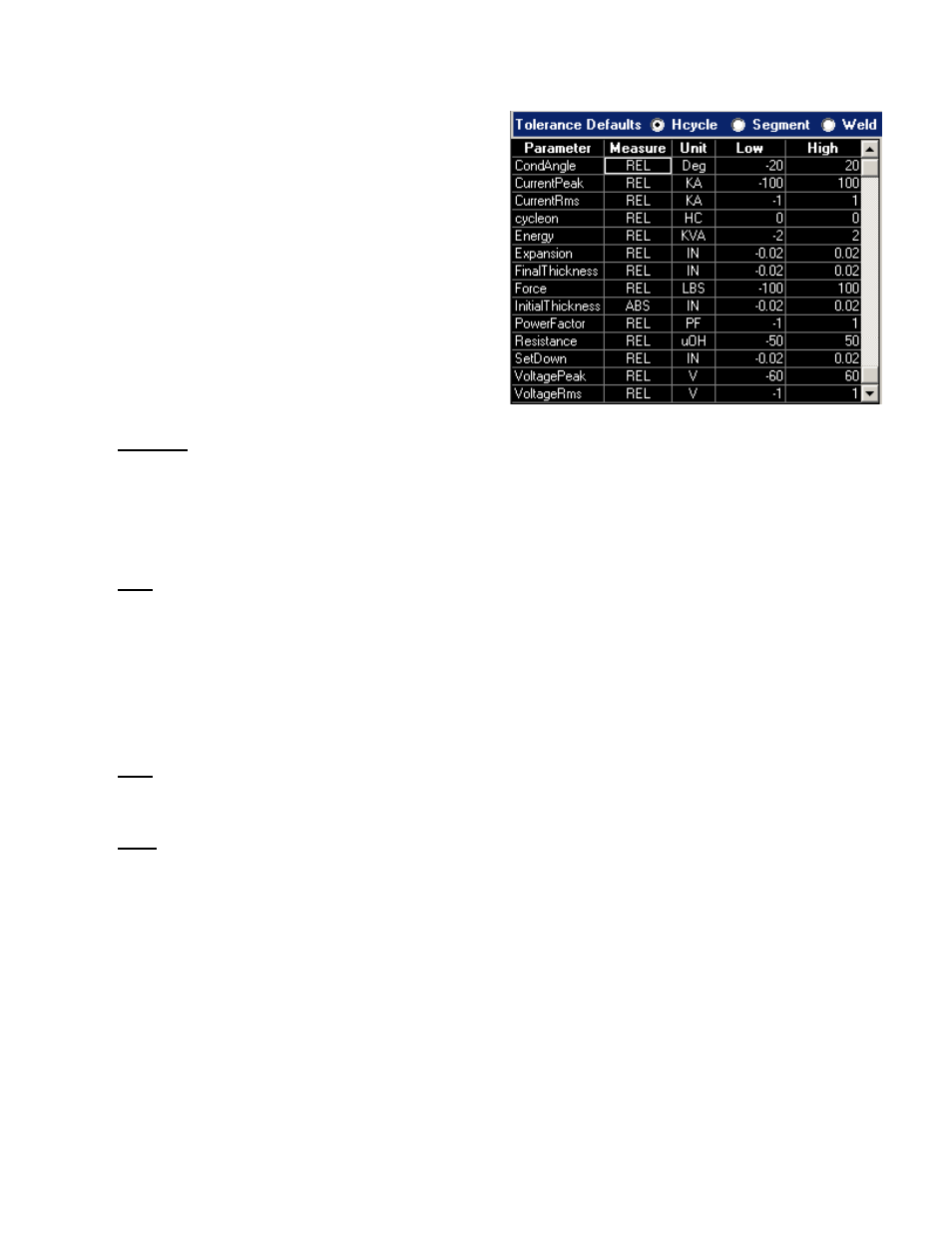

Tolerance Defaults Setup

These tolerance defaults settings are ‘global’ and used

for all IDs.

When a master is first created, the default

measurement mode, units and High/Low limits for

both Halfcycle and Segment displays are specified by

this table. These settings have no impact on any

master that has already been made. Use the radio

buttons at the top of the screen to select the display to

be toleranced.

Note: The input monitor screen units for

displacement are taken from the Initial Thickness

units setting in the Tolerance Defaults table.

• Measure (Tolerancing Mode)

This field can be set to REL or ABS measure for each parameter.

REL – Relative Limits. All tolerance limits are relative to the master.

ABS – Absolute Limits. The master values are ignored, and all limits are absolute.

• Unit

Some parameters can be measured in different units (i.e. inches or millimeters). Change the value

in the Unit field to select the measurement/display units for a data parameter.

NOTE: Units should be chosen prior to setting up a system. Units can be changed after a system

has been calibrated and the reported data will be recalculated to match the new unit. However,

Masters will retain the unit of measure that was set when the master was created. Once the units

have been changed all masters should be deleted and new masters created.

• Low

Set the default Low Limit value for each data parameter.

• High

Set the default High Limit value for each data parameter.

Figure 6-59 Tolerance Defaults Screen