Calibrating force – Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 110

0435-INS-400 Rev. D

8-6

Calibrating Force

An external handheld force gauge is required to determine the exact amount of force that is being

applied during this calibration. If an external force gauge is not available, refer to the note below.

Should you have any problems with your force calibration due to an unusual force sensor and/or

equipment setup, please contact Livingston technical support.

To calibrate the force:

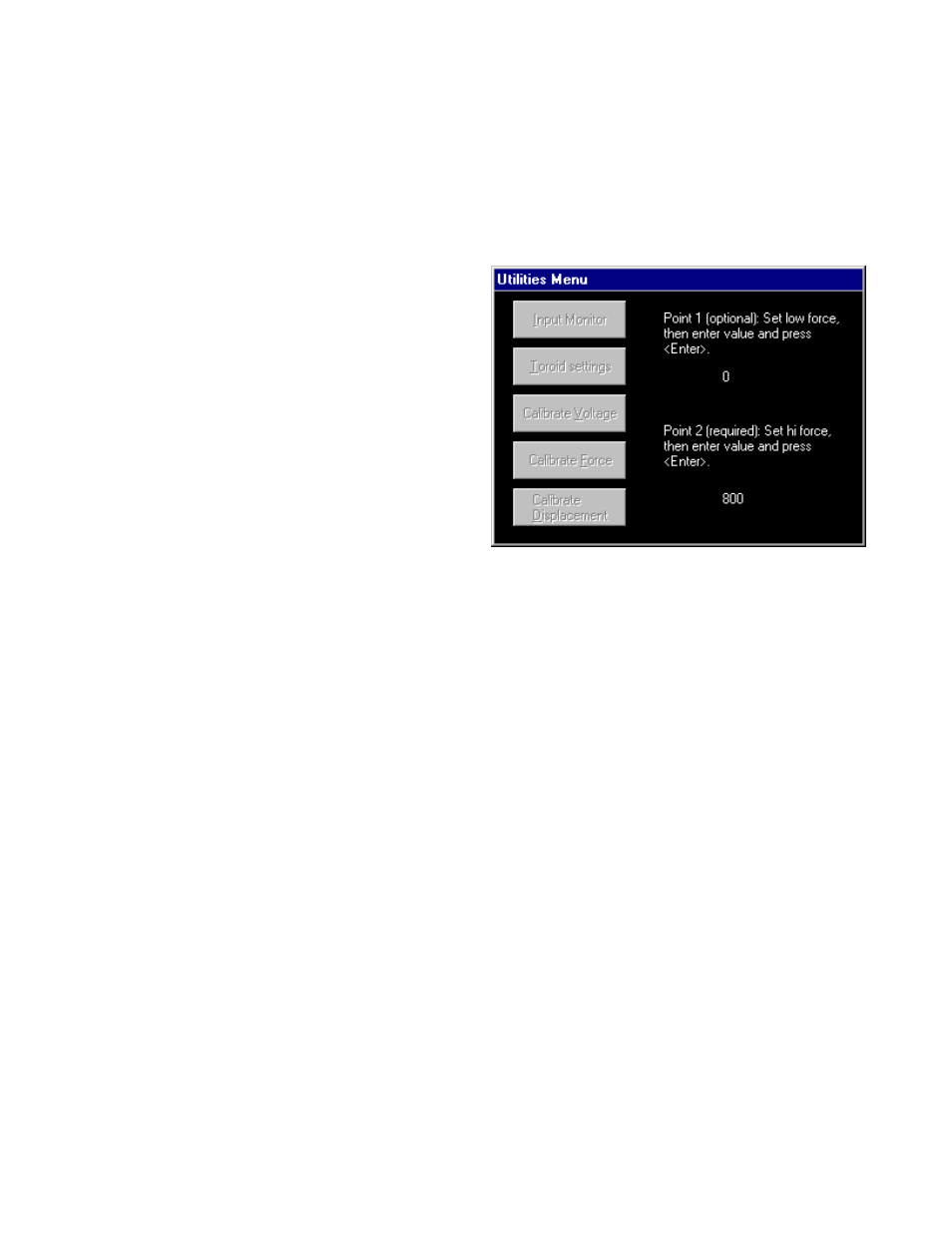

1. From the Utilities Menu, choose the Calibrate

Force option.

2. Depending on the type of welder, you will need

to either:

(a) Set the squeeze force with just enough

pressure to hold the part in place. Using an

external force meter to read the force, enter

Point 1 from the value displayed. This value

is listed as optional, but is highly

recommended to reduce error. Press

ENTER to input the value. Or;

(b) With the electrodes unclamped, enter ‘0’ for

Point 1. This value is listed as optional, but is highly recommended to reduce error. Press

ENTER to input the value.

3. Clamp the electrodes and apply full weld force. Record the Point 2 value as shown on the external

force meter. Press ENTER to input the value.

4. Use the ESCAPE button to exit the screen, then go to the Input Monitor display to check the

values.

Note:

If an external hand-held force gauge is not available, relative force measurement input values

may be calculated as follows:

Air/Oil Cylinder:

Multiply the ratio of the cylinder by the airline pressure (psig). Input this number as the Point 2

value.

For example, a 22:1 cylinder with an 80 psi line pressure:

22*80 = 1760 lbs. (force at the tips)

Enter '1760' in the Point 2 value field.

Figure 8-7 Calibrate Force screen