Problem possible cause or symptom possible fix – Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 139

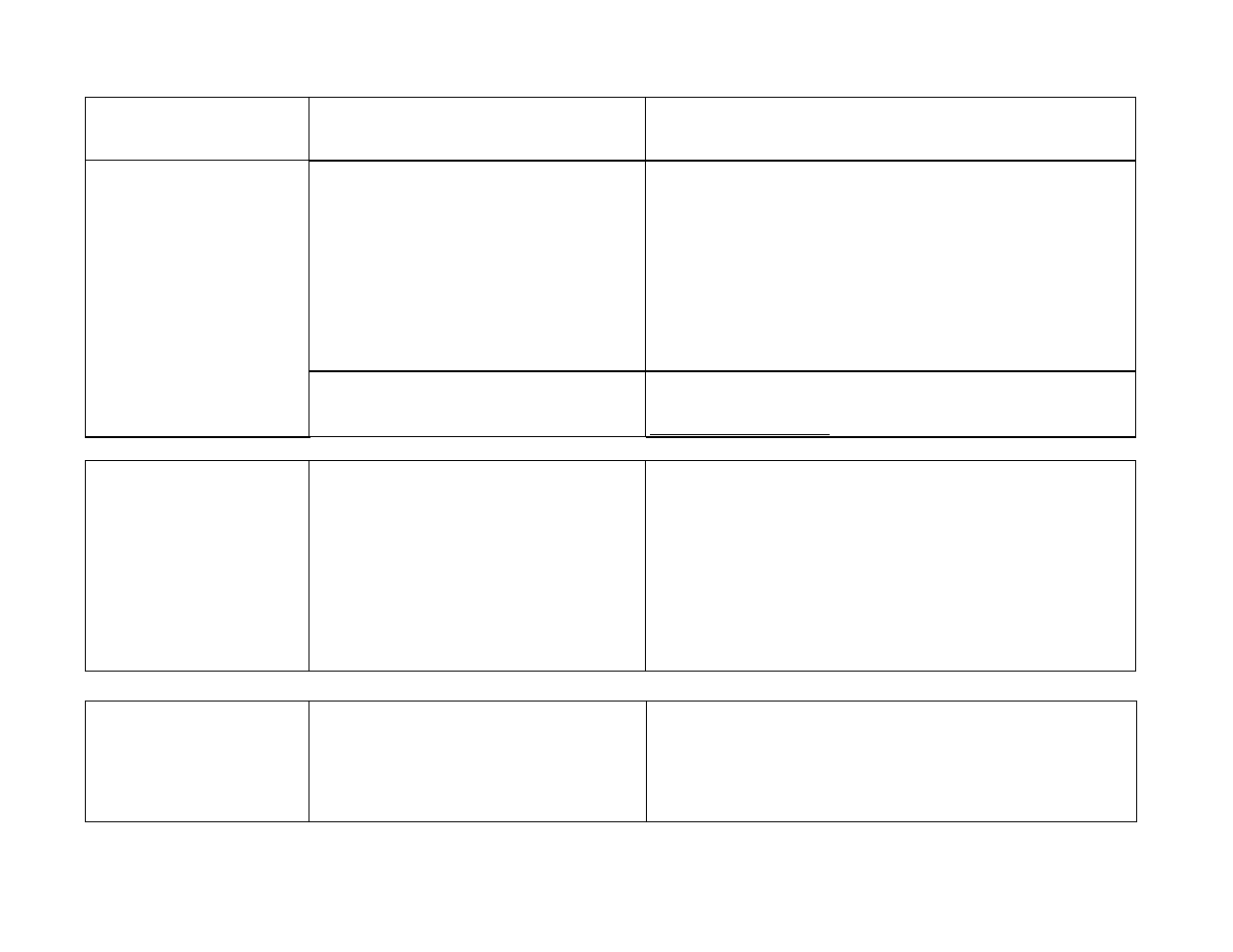

PROBLEM

POSSIBLE CAUSE OR

SYMPTOM

POSSIBLE FIX

Voltage applied to leads is above 9.9 volts. A reading of +/-32767 indicates that the input channel is

saturated and reading its maximum value. It is possible that the

voltage leads were connected too close to the transformer.

Typical readings are between 10V to 15V at the transformer

and depending on the size of the secondary loop will be

approximately 3 to 0.5 volts out at the electrodes. This variation

is due to the voltage drop along the secondary loop. If it is not

possible to connect any closer to the electrodes, inline resistors

can be used to attenuate the incoming voltage.

PEGGED A/D READING:

The Input Monitor

momentarily indicates a

voltage channel A/D

reading of +/- 32767 during

a weld.

Weld monitor has a problem with the

voltage channel.

If the A/D reading remains at maximum value when not

welding (zero volts on the secondary), refer to Section 8,

Trouble With Hardware.

FROZEN A/D READING

(ALL): The Input Monitor

indicates a constant (static)

A/D reading for voltage.

This value never changes;

the other sensor channels do

not change or update either.

Weld monitor problem.

If other channel readings are not changing, the data may not be

updating. Shutdown and restart the weld monitor. If problem

persists contact Livingston Service.

WELDS ARE

RECORDED WHEN THE

WELDER IS NOT

WELDING

.

The transformer secondary is not properly

grounded

Check the transformer for grounding issues. The transformer

secondary should be grounded either directly or through a

grounding inductor. A 1megaOhm resistor in parallel with a

.01microFarad/600V capacitor may also be used.

10-23

0455

-INS-4

00

Re

v.

C