Calibrating voltage – Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 112

0435-INS-400 Rev. D

8-8

Calibrating Voltage

Voltage is calibrated at the factory and does not need to be re-calibrated. If there is an extenuating

circumstance requiring re-calibration of the voltage, use the following procedure. You will need a set

of Livingston voltage leads, a battery and a multimeter to calibrate voltage. A Livingston Voltage

Calibrator may also be used.

Note:

Do not insert paper clips or wire into the connectors. The connector pins may be damaged,

resulting in intermittent readings on the voltage channel.

To calibrate the voltage using a set of voltage leads, a battery and multimeter:

1. Disconnect the green Voltage sensor cable from the voltage leads installed on your welder.

2. Connect the calibration leads to the green cable

connector.

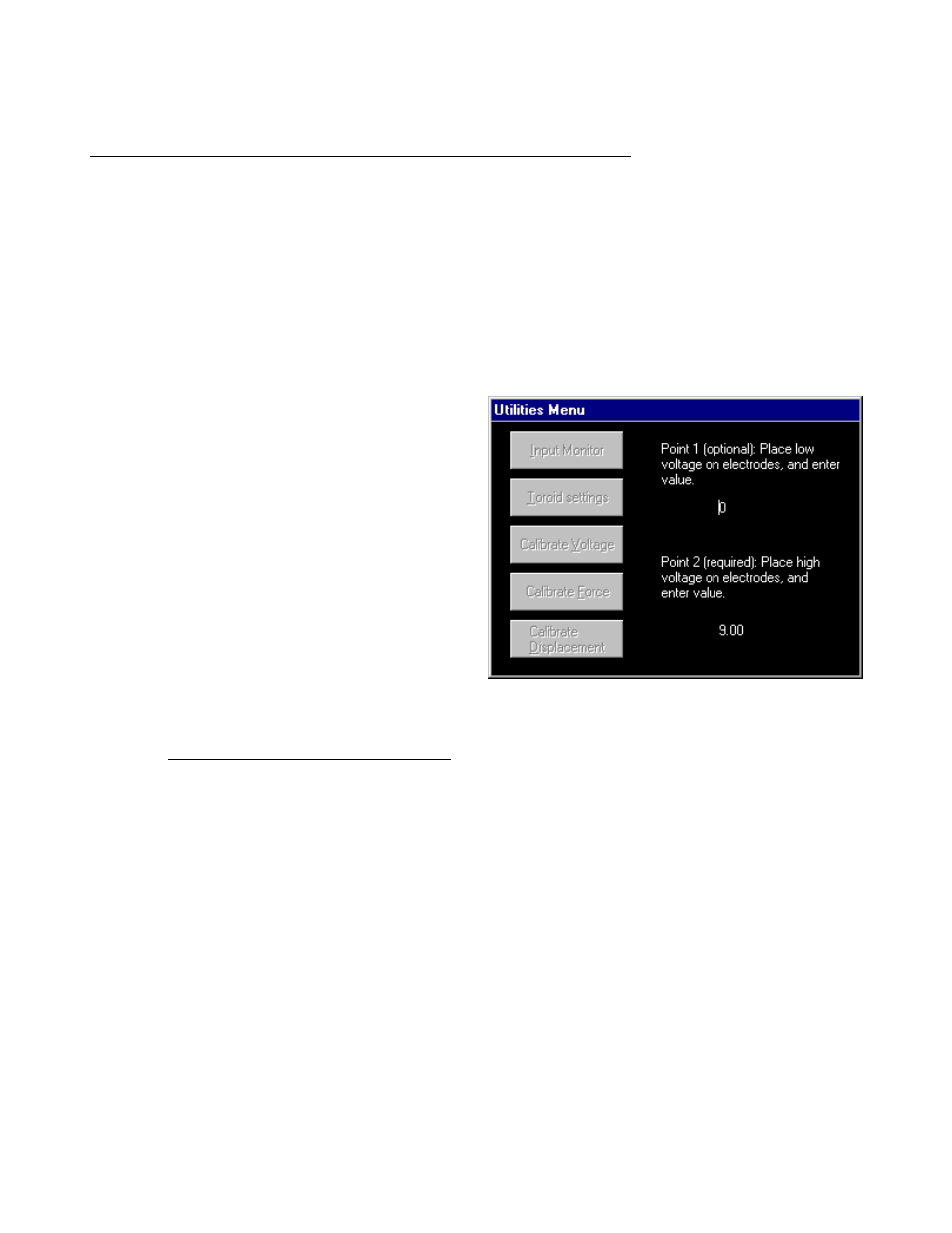

3. From the Utilities Menu, select Calibrate

Voltage.

4. Short the voltage leads together and set the

value to 0. This reading is listed as optional,

but is highly recommended. Click ENTER to

confirm the entry.

5. Connect a 1.5V or 9V battery to the leads. The

red lead is positive; the black lead is negative.

Make sure the DC voltage polarity is observed

during calibration. Take the voltage reading of

a battery using a multimeter while it is still

connected. With the leads still connected to the battery, set the entry for Point 2 to the known

value. This value must be entered to proceed. Press ENTER to input the value.

Note: The Maximum input for voltage channel is 9.5V, channel will saturate at 10V.

6. Use the ESCAPE button to exit.

7. Go back to the Input Monitor screen and compare the incoming values on the voltage channel

with the leads shorted together as well as with the battery connected.

To calibrate the voltage using a Livingston Voltage Calibrator:

Follow the instructions that came with the Voltage Calibrator.

Figure 8-8 Calibrate Voltage screen.