Problem possible cause or symptom possible fix – Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 128

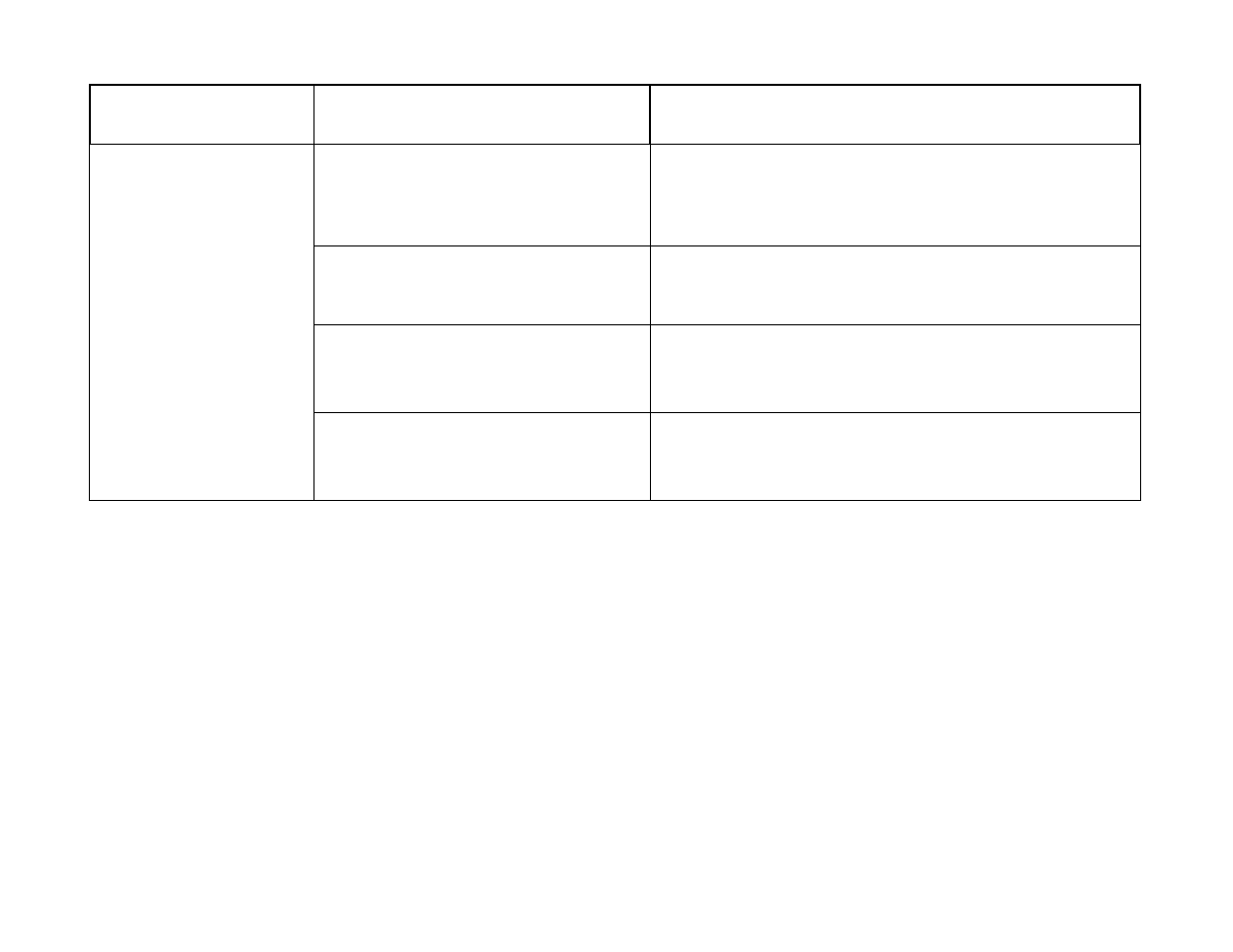

PROBLEM

POSSIBLE CAUSE OR

SYMPTOM

POSSIBLE FIX

Tolerances are improperly adjusted.

Analyze the weld data and process to determine which

parameters need tighter tolerances to REJECT defective welds.

Displacement sensor was not zeroed before

a new Master was created. Displacement

readings are inaccurate or static.

Check the zero reference of displacement sensor and zero if

necessary. Create a new Master or set of Master Tolerance

Limits and examine the weld data for inconsistencies.

A sensor was not calibrated correctly

before a new Master was created, or was

recalibrated after the master was created.

Using the Input Monitor, check the calibration of the sensors

and recalibrate if necessary. Create a new Master or set of

Master tolerance limits and examine the weld data for

inconsistencies.

WELDS THAT SHOULD

BE REJECTED ARE

NOT BEING

REJECTED: The weld

summary screen indicates

that welds have an ACCEPT

status of "0" for parts that

should be REJECTED.

A sensor is malfunctioning and a new

Master was created. Sensor readings are

inaccurate or static.

Using the Input Monitor, check the calibration of the sensors

and recalibrate if necessary. Create a new Master or set of

Master tolerance limits and examine the weld data for

inconsistencies.

10-12

04

55

-IN

S-

40

0 Re

v. C