Calibrating displacement, Zeroing the displacement – Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 109

0435-INS-400

Rev.

D

8-5

Calibrating Displacement

Livingston strongly recommends fabricating two different gauge blocks that fit into the welding

electrodes for displacement calibration. Typically, these blocks are made of hardened steel. The first

block should be equal to the stack-up thickness of the parts to be welded. The second block should

have a known thickness that is not more than 4.5% of the overall stroke of the sensor. For example, a

gauge block for a sensor with a 4-inch stroke should be of a thickness generally around half and no

greater than 0.180 inches.

These blocks can be chained to the machine for easy access.

To calibrate the displacement:

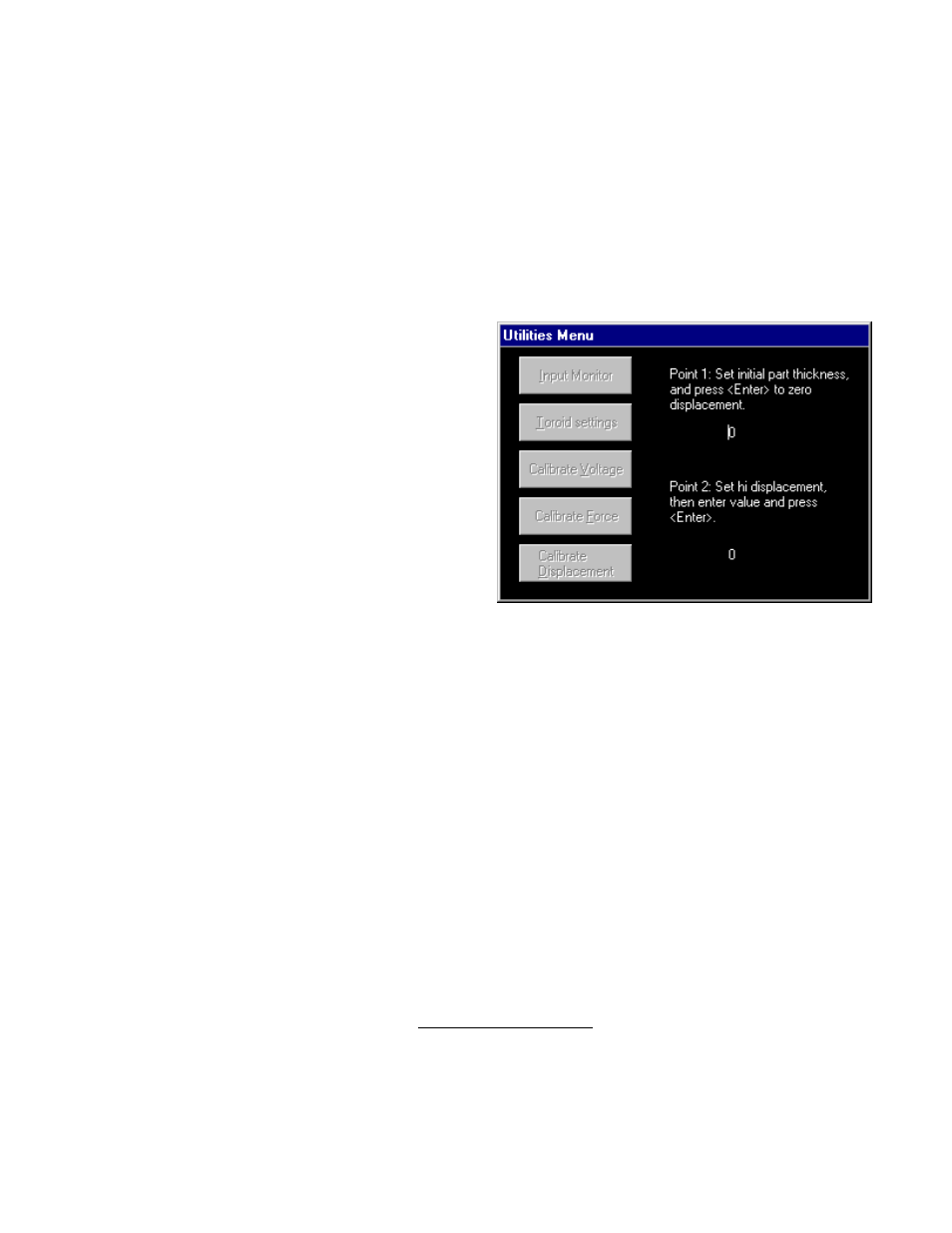

1. From the Utilities Menu, choose the Calibrate

Displacement option.

2. Place a gauge block equaling the stack-up

thickness of the parts to be welded between the

weld head electrodes. Close the weld head

electrodes on the gauge block.

3. Enter '0' for the Point 1 value and press ENTER.

(This does exactly the same thing as the Zero

Displacement Button. Refer to the section

below for more details).

4. Open the weld head electrodes and add a second

gauge block of known thickness on top of the first block. Close the weld electrodes onto the blocks

and enter the known thickness of the gauge block as the Point 2 value and press ENTER.

5. Select ESCAPE to exit the window. Return to the Input Monitor screen and check the readings

both with and without the second gauge block in place. The values displayed should correspond to

those that were entered when calibrating the displacement sensor.

Note

: If it is not possible to position two known thicknesses, calibration may be done with the tips

together. Zero with the electrodes closed together, then use a shim or washer of a known thickness

placed between the electrodes for calibration. Once you have verified the values with the Input

Monitor re-zero with the full part stack-up clamped up.

Zeroing the Displacement

The Zero Displacement button on the Input Monitor screen centers the range of the displacement

readings so that incoming values will be within the appropriate measurement range. The monitoring

program compensates for the incoming voltage readings to establish a mid-range setting at the

appropriate sensitivity. Refer to Chapter 6, WMS Reference Guide for more details.

Figure 8-6 Calibrate Displacement screen