Wms quick start guide – Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 35

0432-INS-400 Rev. E

5-1

WMS Quick Start Guide

This chapter is a quick how-to guide to begin using a Livingston weld monitor. The provided example

describes the necessary steps to collect and view data, create a master and set tolerances.

Note:

Since this is only an example, it assumes the following:

- All hardware has been properly installed, all sensors have been properly calibrated, and the

2400 is turned on and ready to monitor;

- You are familiar with how to navigate and edit functions within the WMS program (see

Chapter 4, Getting Familiar With The WeldWise

™

2400).

Due to the variety of welding processes and schedules throughout the welding industry, the following

example steps may not be applicable to every welding process. For a complete description of all

functions in the WMS program, refer to Chapter 6, WMS Reference Guide.

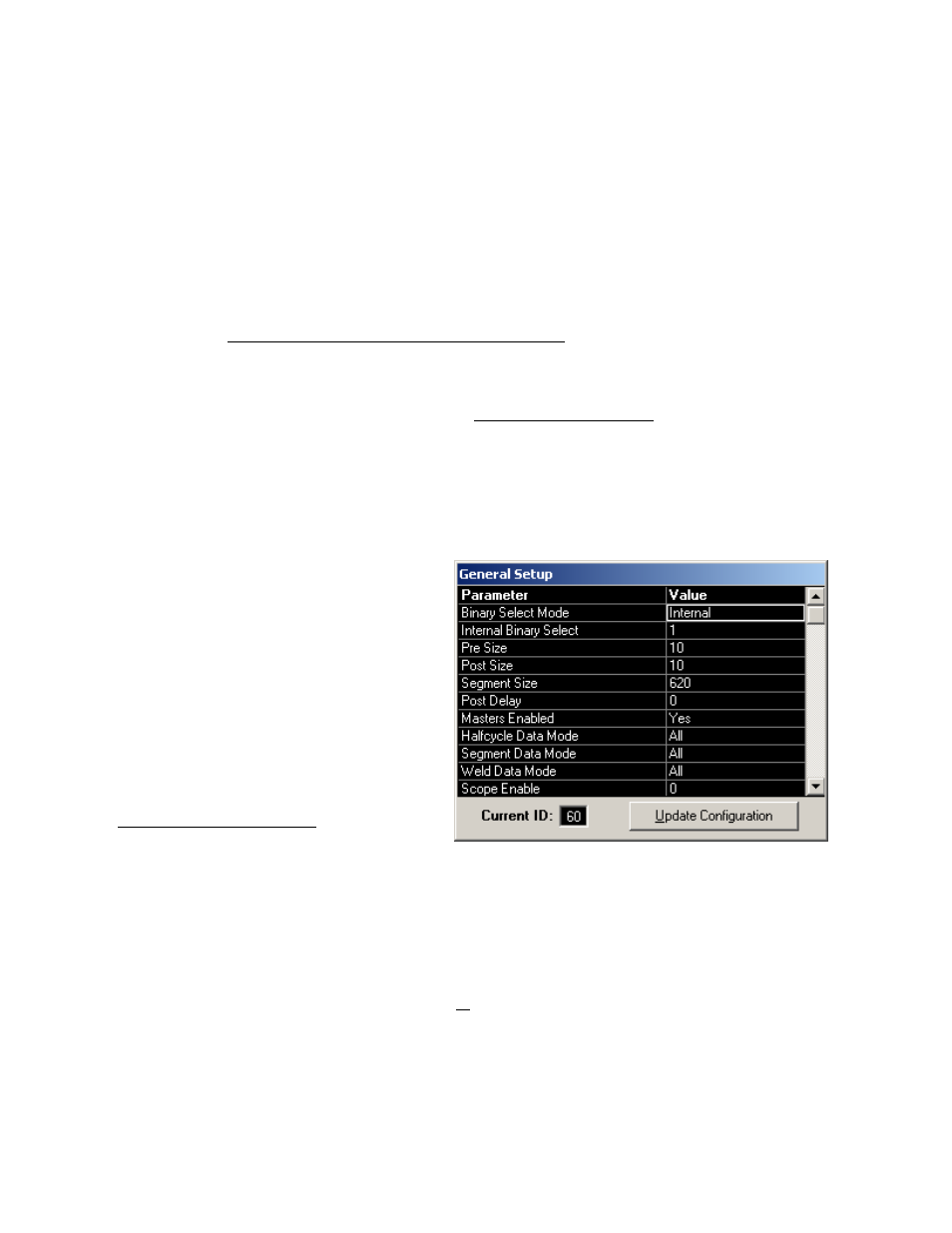

General Setup

The first step is to confirm that the general configuration settings are appropriate for this procedure.

1. With the equipment set up for monitoring

and the WMS program running, go to the

Main Menu. Select Setup, then General

Setup.

2. Current ID should be set to 60.

3. For the purposes of this example, set the

General Setup parameters to the following

values (parameters not mentioned here can

be left at their default settings). Refer to

the General Setup Menu in Section 6,

WMS Reference Guide, for parameter

specifics.

Pre Size = 10

Halfcycle Data Mode = All

Post Size = 10

Segment Data Mode = All

Post Delay = 0

Weld Data Mode = All

Masters Enabled = Yes

Segment Tolerance Mode = Average

Segment Size = 100

4. Once these changes have been made, use the Update Configuration button to update settings to the

weld monitor.

5. ESCAPE to the main program screen.