Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 78

0433-INS-400 Rev. E

6-32

GENERAL SETUP - Parameter Descriptions

• Binary Select Mode (Default Setting: Internal)

Binary Select inputs are to select different masters for a single weld head. For each ID there are up

to 15 masters which can be on line, and immediately available for use. This is useful when a single

weld head has several weld schedules. Typically the binary select number corresponds with the

weld schedule number or the sequential order of welds made the welder during a part cycle.

Internal: The binary select is set to the Internal Binary Select setting in the General Setup Menu

(see below).

External: The Binary Select is determined by the status of the Binary Select inputs located at the

rear panel of the 2400. A Binary Select of 0 is invalid.

• Internal Binary Select (Default Setting: 1)

The Internal Binary Select value is only used if the Binary Select Mode is set to Internal. The

Internal Binary Select should be set to a number from 1 to 15. In internal mode, all masters created

will be associated with this Binary Select.

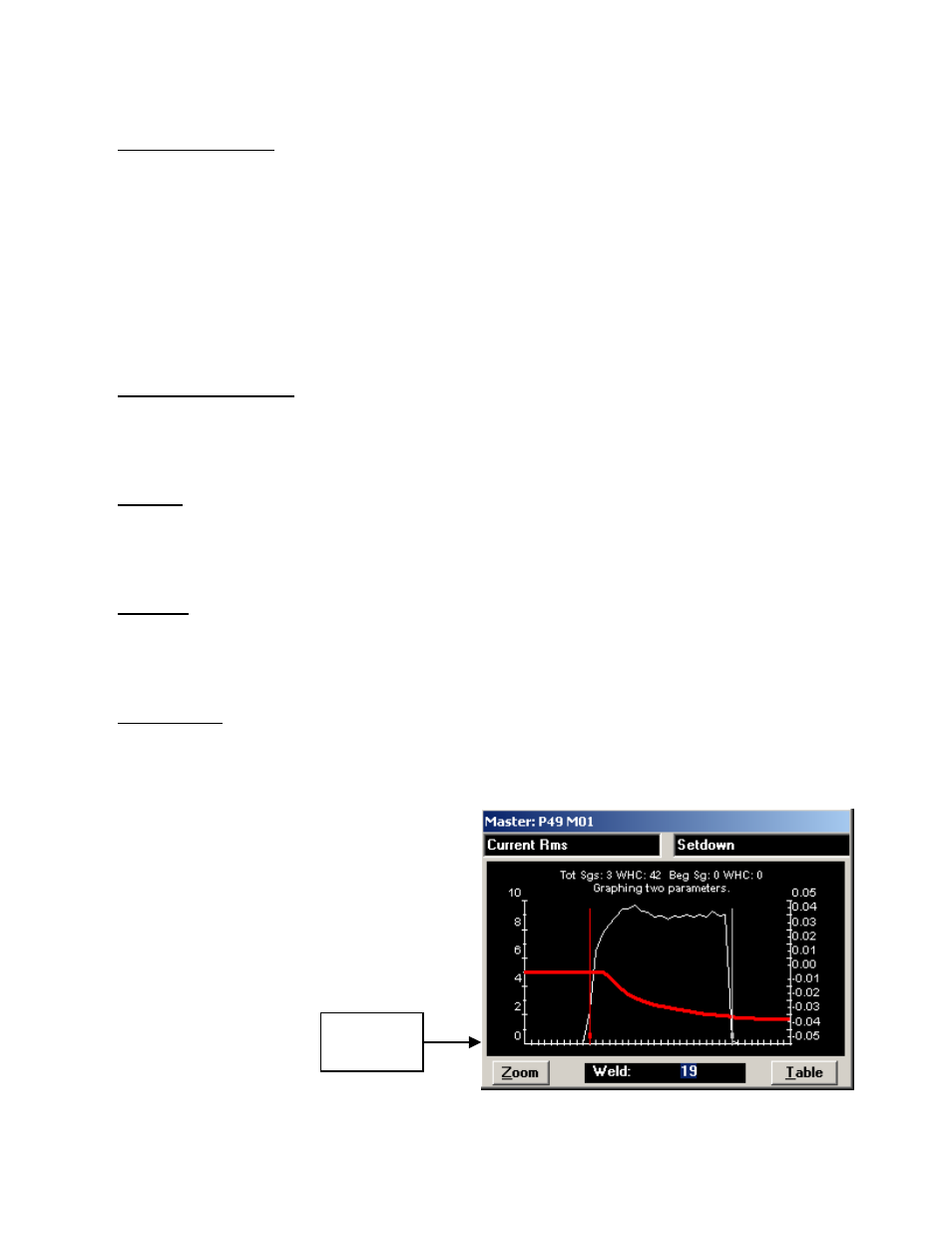

• Pre Size (Default Setting: 10) (see figure 6-50)

This setting determines the amount of time in halfcycles that data is recorded before the weld

current begins. It is recommended that the Pre be set to less than the ‘Squeeze’ time used for the

weld schedule.

• Post Size (Default Setting: 10) (see figure 6-50)

This setting determines the amount of time in halfcycles that data is recorded after the weld current

ends. It is recommended that the Post be set to slightly less than the ‘Hold’ time used for the weld

schedule, yet long enough for the weld to have solidified.

• Segment Size (Default Setting: 620) (see figure 6-50)

The Segment Size setting determines the maximum number of halfcycles (amount of time) that

data is recorded after weld current begins until the weld current ends. This setting should be set to

a number higher than the expected number of halfcycles in the weld.

Note that Weld Segment data is truncated to

the actual number of halfcycles in the weld.

The Segment Size is the maximum number of

halfcycles that will be recorded in the weld

segment when making a master. If a master is

being used and masters are enabled, then the

master’s segment size data will override this

setting.

PRE

WELD

SEGMENT

POST

Halfcycle

axis

Figure 6-50 Segment Size sets the maximum

weld segment size