Tolerancing – Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 44

0432-INS-400 Rev. E

5-10

Tolerancing

In the WMS program, welds are accepted or rejected based on specific tolerances assigned for

individual parameters within an active master. Tolerances can be defined as relative or absolute values.

Refer to the Tolerancing in section 6, WMS Reference Guide, for a definition of relative and absolute

tolerances.

As weld data is recorded and compared to the master tolerance limits, the monitor flags values that are

out of tolerance. In this section, we'll change the tolerances for the master that was just made and then

accept / reject welds based on those master tolerance limits.

1. From the Main Menu, select Tolerancing.

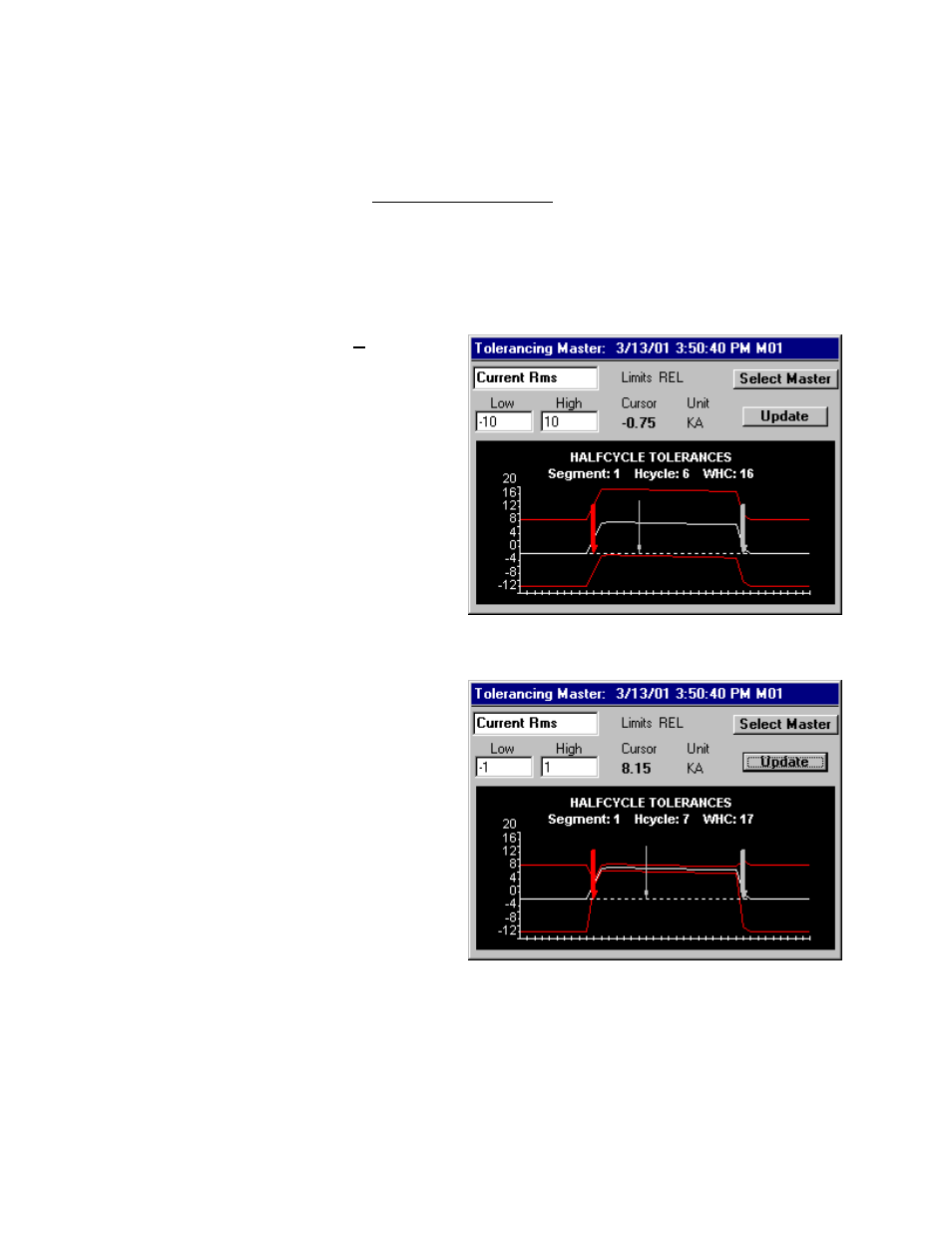

If nothing comes up, press the Select

Master button and highlight the master we

just made. Press SELECT. Your screen

should look similar to figure 5-18.

2. Touch anywhere in the Weld segment

(middle of the screen) so that the pointer

(thinnest vertical arrow) is in Segment 1

(Weld segment). Under

HALFCYCLE

TOLERANCES

, the screen should say

Segment: 1.

3. Select the parameter Current Rms.

4. Select the Low number and change it to –1.

Select the High number and change it to 1.

5. Press the Update button. After a few

moments, the screen should now look

similar to figure 5-19. Notice that the

tolerance bands have adjusted accordingly.

6. ESCAPE to the main screen and make a

weld. If the weld passes, go to the Halfcycle Summary screen. Your Halfcycle Summary screen

should look similar to figure 5-20. Notice that the Current Rms line is within the set tolerances.

Now we'll lower the heat for the next weld so you can see what happens.

Figure 5-18 Tolerancing screen

Figure 5-19 Master with Low/High tolerances

changed