Problem possible cause or symptom possible fix – Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 135

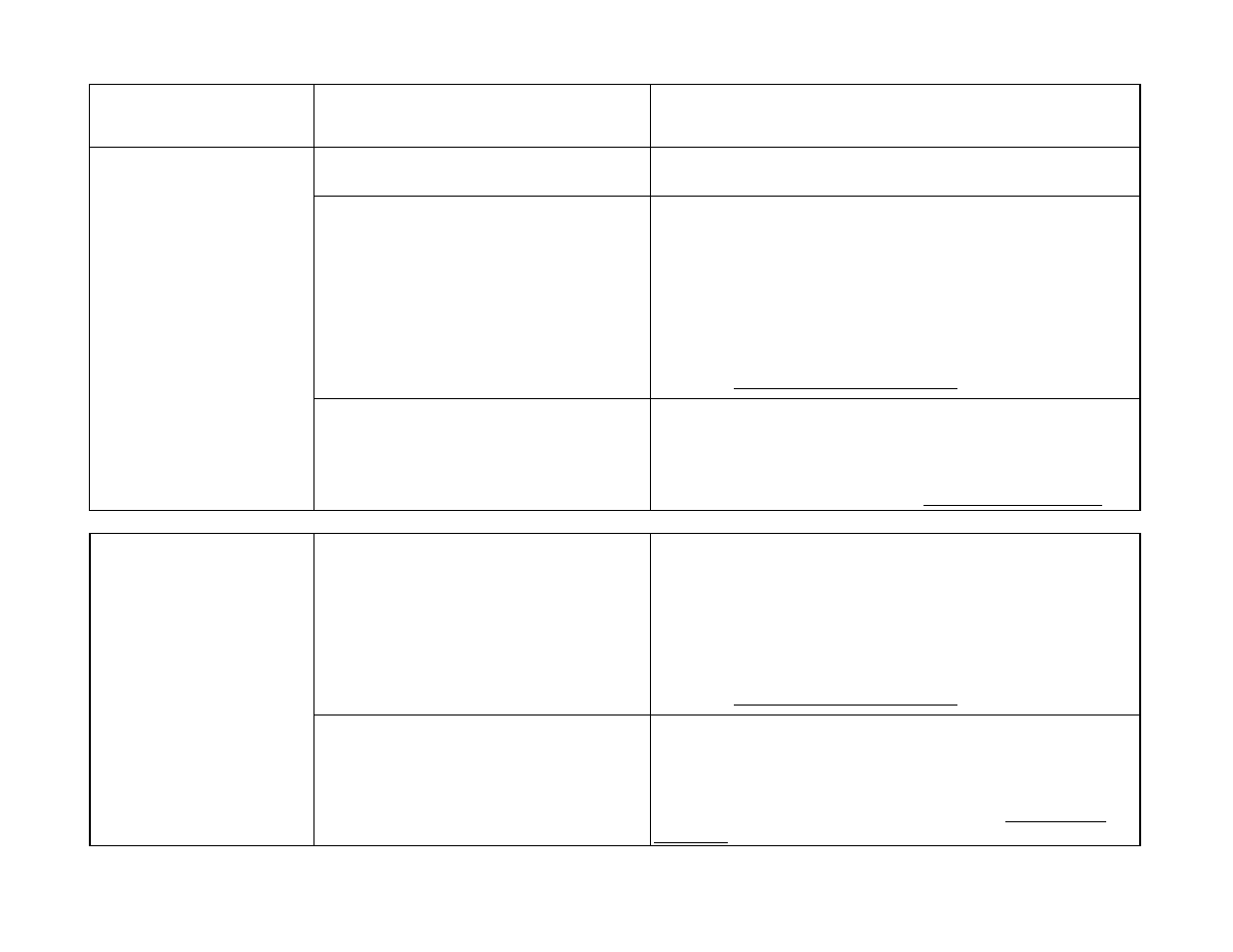

PROBLEM

POSSIBLE CAUSE OR

SYMPTOM

POSSIBLE FIX

The sensor was not zeroed (displacement

only).

Zero the displacement sensor. If the sensor will not zero, the

sensor, sensor cable or weld monitor may be malfunctioning.

Sensor failure.

A reading of +/-32767 indicates that the input channel is

saturated and reading its maximum value. There may be a

problem with the sensor, sensor cable, or weld monitor.

Disconnect the sensor from the sensor cable. If the A/D reading

changes to a value of less than 100, the sensor may be

malfunctioning. Repair or replace the sensor. If the A/D reading

remains at maximum value then the sensor may be OK and the

sensor cable or weld monitor may be malfunctioning. Refer to

Section 6, Possible Sensor Cable Failure.

PEGGED A/D READING:

The Input Monitor

indicates a displacement

channel A/D reading of +/-

32767. This value never

changes; the other sensor

channels appear to be

working and the A/D values

for these channels are

changing/updating.

Sensor cable failure.

Disconnect the sensor from the cable, if still pegged.

Disconnect cable from the weld monitor. If the A/D reading

changes to a value within +/- 100 from 0, the sensor cable

should be repaired or replaced. If the A/D reading remains at

maximum value, refer to Section 8, Trouble With Hardware.

Sensor failure.

A static reading may indicate a problem with the sensor, sensor

cable, or weld monitor. Disconnect the sensor from the sensor

cable. If the A/D reading changes to a value of less than 100,

the sensor may be malfunctioning. Repair or replace the sensor.

If the A/D reading remains at the same value or does not change

to a value of less than 100, the sensor may be OK and the

sensor cable or weld monitor may be malfunctioning. Refer to

Section 6, Possible Sensor Cable Failure.

FROZEN A/D READING

(DISPLACEMENT

ONLY): The Input

Monitor indicates a

constant (static) A/D

reading for the displacement

sensor. This value never

changes; the other sensor

channels appear to be

working and the A/D values

for these channels are

changing/updating.

Sensor cable failure.

Disconnect the sensor from the cable, if value remains the

same. Disconnect cable from the weld monitor. If the A/D

reading changes to a value within +/- 100 from 0, the sensor

cable should be repaired or replaced. If the A/D reading

remains at maximum value, refer to Section 8, Trouble With

Hardware.

10-19

0455

-INS-4

00

Re

v.

C