Problem possible cause or symptom possible fix – Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 126

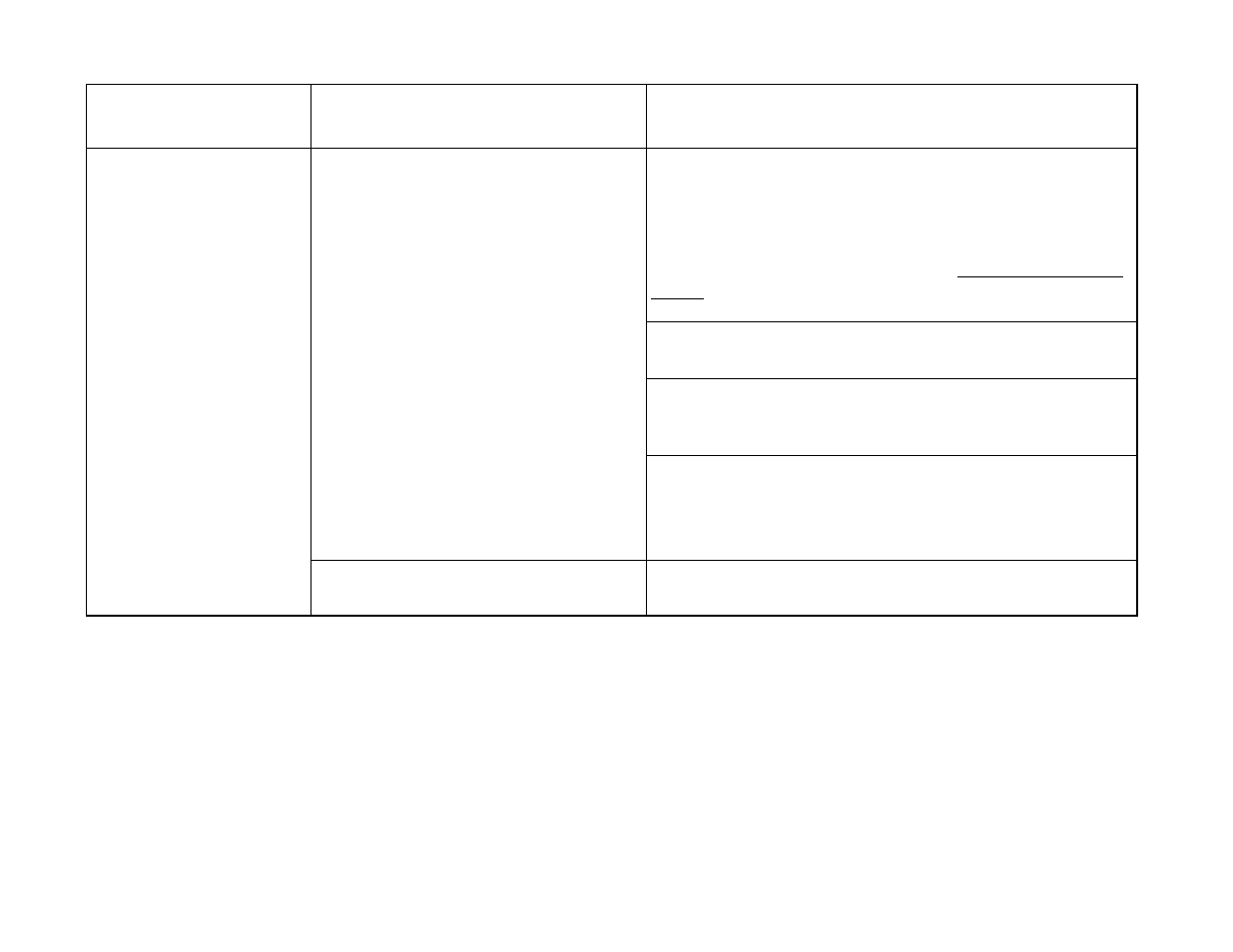

PROBLEM

POSSIBLE CAUSE OR

SYMPTOM

POSSIBLE FIX

Inspect sensor cable for physical damage. A cable that is

deformed, severed, partially severed, shredded, abraded and/or

has bare wires showing may be suspect. Disconnect sensor

cable from the weld monitor and replace. Try to reposition new

cable to avoid recurring damage. Spiral wrap or guards will also

help to protect cable. Refer to Section 6, Possible Sensor Cable

Failure.

Inspect electrical connections for damage, poor connections

and/or corrosion. Replace connectors and/or cable.

Using the cable pinout documentation for your system, check

the continuity of all connections relating to this sensor. Repair

or replace cable as necessary.

Sensor cable failure.

Disconnect the sensor cable from the weld monitor & sensor

and then using Livingston sensor cable documentation, check

continuity of all connections within the cable. Repair or replace

cable as necessary.

EVERY WELD IS

REJECTED: The Weld

Summary screen indicates

that Current, Voltage,

Energy, Resistance or

Conduction Angle

Parameters are out of

tolerance

.

CONT'D

Toroid failure.

Inspect the toroid for physical damage or abrasion. Inspect for

loose buckle. Replace and/or relocate toroid if necessary.

10-10

04

55

-IN

S-

40

0 Re

v. C