Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 103

0434-INS-400 Rev. C

7-9

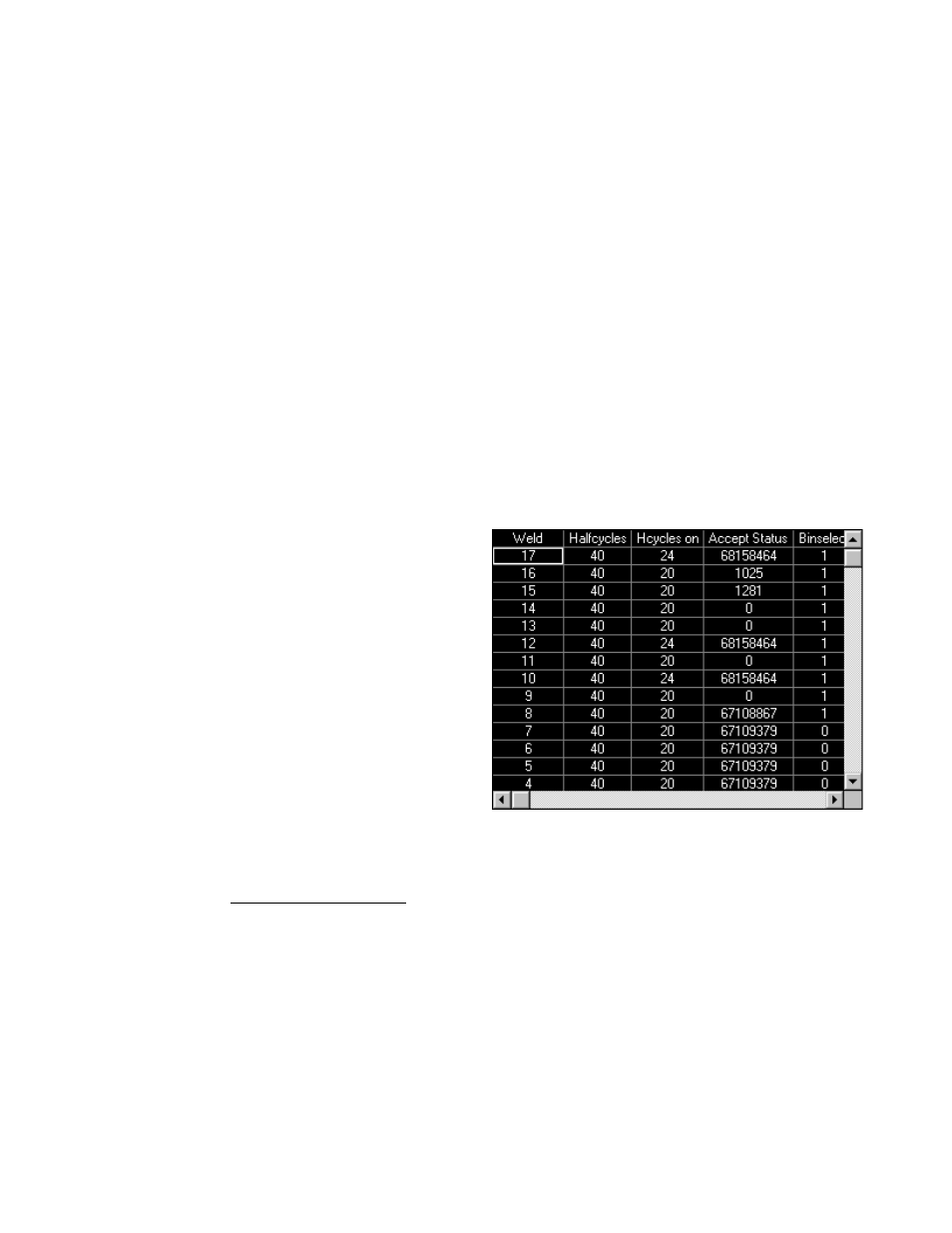

Figure 7-6 Weld Summary screen

To perform a quick test of the sensor installation:

1. With the sensors connected and the WeldWise™ 2400 turned on, set up the welder as usual to

perform a weld. The monitoring of weld events is triggered by current detection and is preset, so no

further setup is required to begin recording values during welding.

2. Make a few welds.

3. Note the values that appear on the monitor's main program screen. If the parameters CurrentRms

and VoltageRms are not already displayed on the weld monitor's screen, click

any parameter box

on the screen itself, click the SELECT key on the Virtual Key-pad and then use the Arrow Keys to

scroll through the various parameters until CurrentRms is displayed. Press ENTER to show

incoming readings for that parameter. Do the same with another parameter box and select

VoltageRms. The graphic display indicates the levels of the sensor readings for these factors and

these values are recorded for the weld.

Note: Readings will be uncalibrated, as the sensors have not been calibrated yet. Calibration is covered

in Chapter 8, Calibrating the Sensors

4. Click the MENU button on the Key-pad.

5. Select the Data option from the Main Menu.

6. Select Weld Summary. The program displays

the data collected for the welds, organized by

weld number, as shown in figure 7-7. For each

weld made, the Halfcycle count should be twice

the amount of cycles in the weld. For example,

a schedule with 5 cycles of Squeeze, 10 cycles

of Weld and 8 cycles of Hold would have 46

total halfcycles (5 + 10 + 8 = 23, 23 times 2 =

46). Use the Arrow Keys to scroll through the

various headings to view readings for Current,

Voltage, Force and Setdown/Expansion

(Displacement).

If any of these operations don't work as described, recheck the setup instructions in this chapter or

consult Chapter 6, WMS Reference Guide.