Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 133

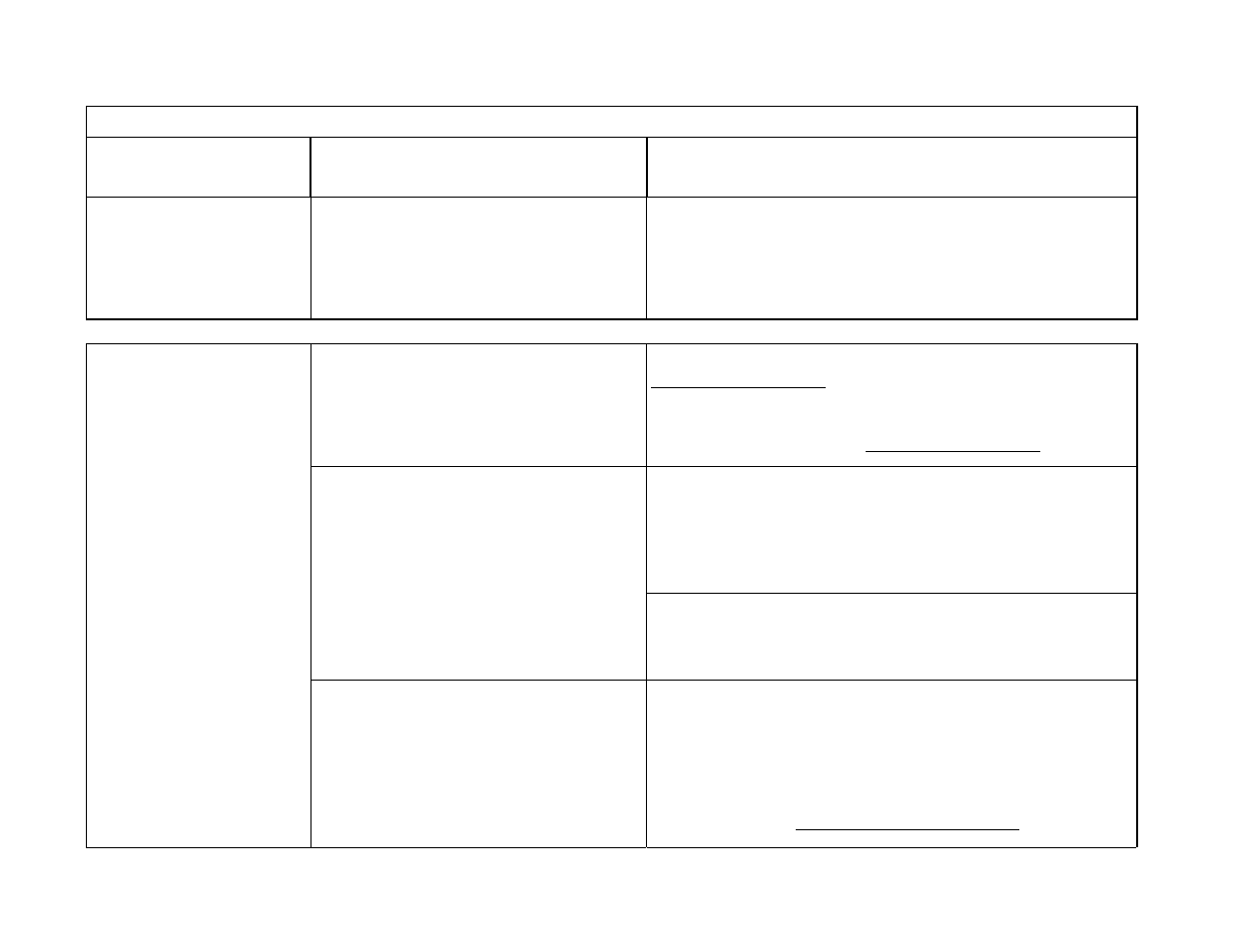

3. TROUBLE WITH DISPLACEMENT SENSOR, READINGS OR CHANNEL

PROBLEM

POSSIBLE CAUSE OR

SYMPTOM

POSSIBLE FIX

CALIBRATED

DISPLACEMENT

SIGNAL IS READING

HIGHER OR LOWER

THAN NORMAL

The sensor was not zeroed.

Zero the displacement sensor.

Calibration has changed.

Inspect and recalibrate sensor if necessary (Refer to Chapter 8,

Calibrating the Sensors). Note: If an Export Setup was

performed the last time this sensor was properly calibrated, an

Import Setup may be performed to reload the saved calibration

settings. Refer to Chapter 6, WMS Reference Guide.

Inspect sensor for physical damage. Inspect electrical

connections for poor connections or corrosion. Try recalibrating

sensor if the sensor will not calibrate or A/D readings don’t

look right. Test the sensor Independent of the Livingston

system.

Sensor failure.

Test the sensor independent of the Livingston System by using

an Oscilloscope. Different model sensors may require different

methods of testing. Call Livingston & Co. for details regarding

the testing of your sensor.

CALIBRATED

DISPLACEMENT

SIGNAL IS INDICATING

A “FROZEN” (static)

READING

Sensor Cable or weld monitor failure.

Inspect sensor cable for physical damage. A cable that is

deformed, severed, partially severed, shredded, abraded and/or

has bare wires showing may be suspect. Disconnect sensor

cable from the weld monitor and replace with a spare sensor

cable. Try to reposition the new cable to avoid recurring

damage. Spiral wrap or guards will also help to protect cable.

Refer to Section 6, Possible Sensor Cable Failure.

10-17

0455

-INS-4

00

R

ev

. C