Problem possible cause or symptom possible fix – Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 132

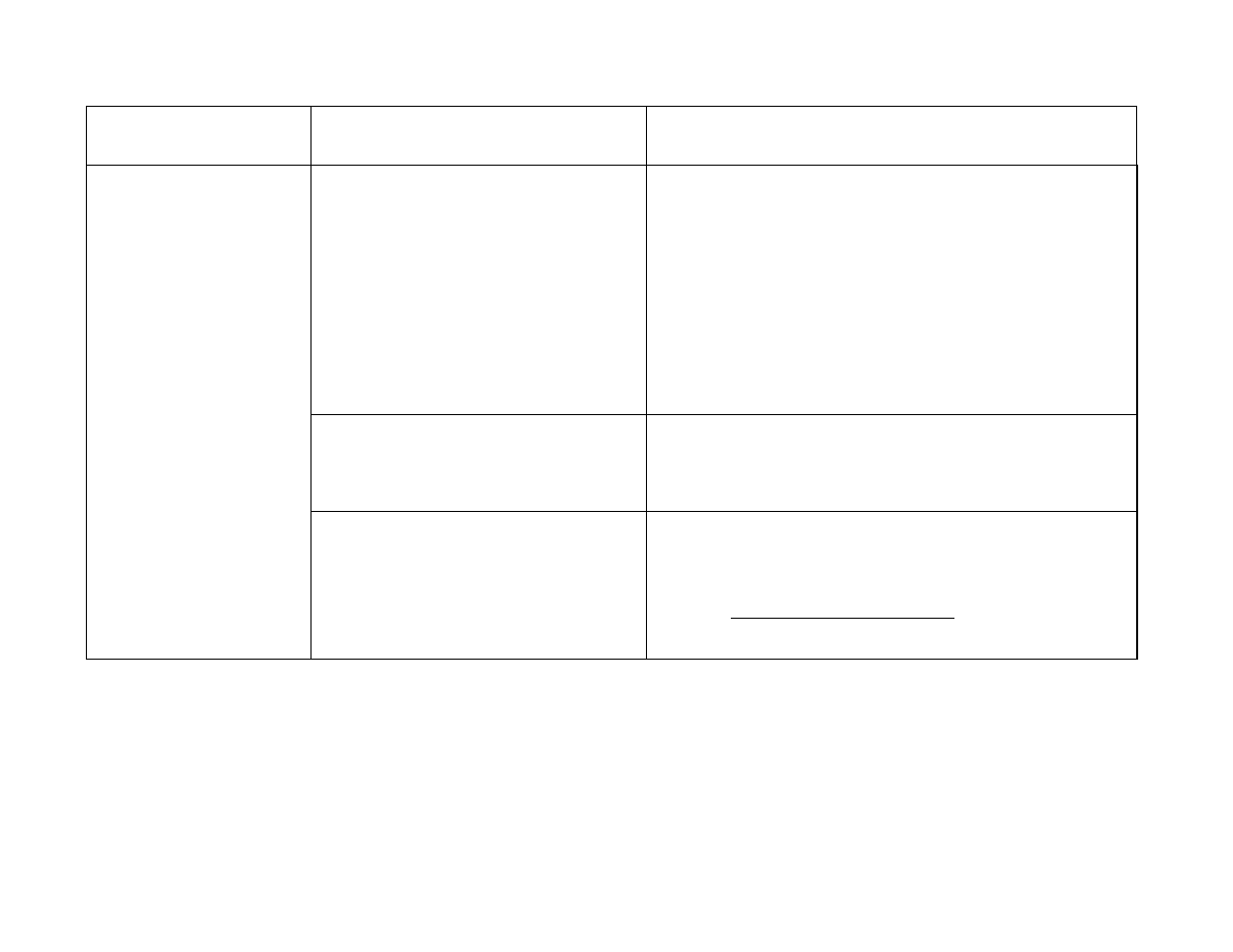

PROBLEM

POSSIBLE CAUSE OR

SYMPTOM

POSSIBLE FIX

Sensor failure.

A damaged force sensor may result in an offset or inaccurate

readings. Use the Input Monitor to observe the force channel

readings, then refer to the force sensor manufacturer

specifications and determine what the mV output of the sensor

should be at a given force. +/-32767 A/D readings are

equivalent to +/- 20mV. Apply and remove force and see if the

A/D input readings compare to what the sensor readings should

be. If the values seem to be incorrect, there may a problem with

the sensor, sensor cable, or weld monitor hardware. Try using a

known good spare sensor cable and/or weld monitor. If the

readings still appear to be incorrect, replace the sensor.

Sensor cable failure.

Try using a spare sensor cable. Apply and remove force and see

if the A/D input readings compare to what the sensor readings

should be. If the values are still incorrect, there may be a

problem with the sensor or weld monitor.

INACCURATE A/D

READINGS: The Input

Monitor indicates the force

sensor A/D readings are

changing but the readings

may not be correct.

Weld Monitor failure.

Try using a spare weld monitor. Apply and remove force and

see if the A/D input readings compare to what the sensor

readings should be. If the values are still incorrect then there

may be a problem with the sensor or the sensor cable. Refer to

Section 6, Possible Sensor Cable Failure.

10-16

04

55

-IN

S-

40

0 Re

v. C