Selecting a master, Tolerances, Figure 3-1 weld data showing force and current – Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 26: Figure 3-2 example of a weld lobe for force

0430-INS-400 Rev. D

3-2

remain clamped until the ladder logic has been reset). Parts with rejected welds can then be

immediately identified and isolated from parts with accepted welds.

Selecting a Master

A Livingston weld monitor can store a number of masters (contains master tolerance limits) that are

selectable using the binary select inputs. Selecting different masters is desirable for weld heads that

make more than one weld perhaps with a different weld schedule or different part stack up. Please refer

to the General Setup Menu section in this manual for more information on binary select modes. The

WeldWise 2400 Binary Select inputs are 24V discrete connections located on the rear of the monitor.

Tolerances

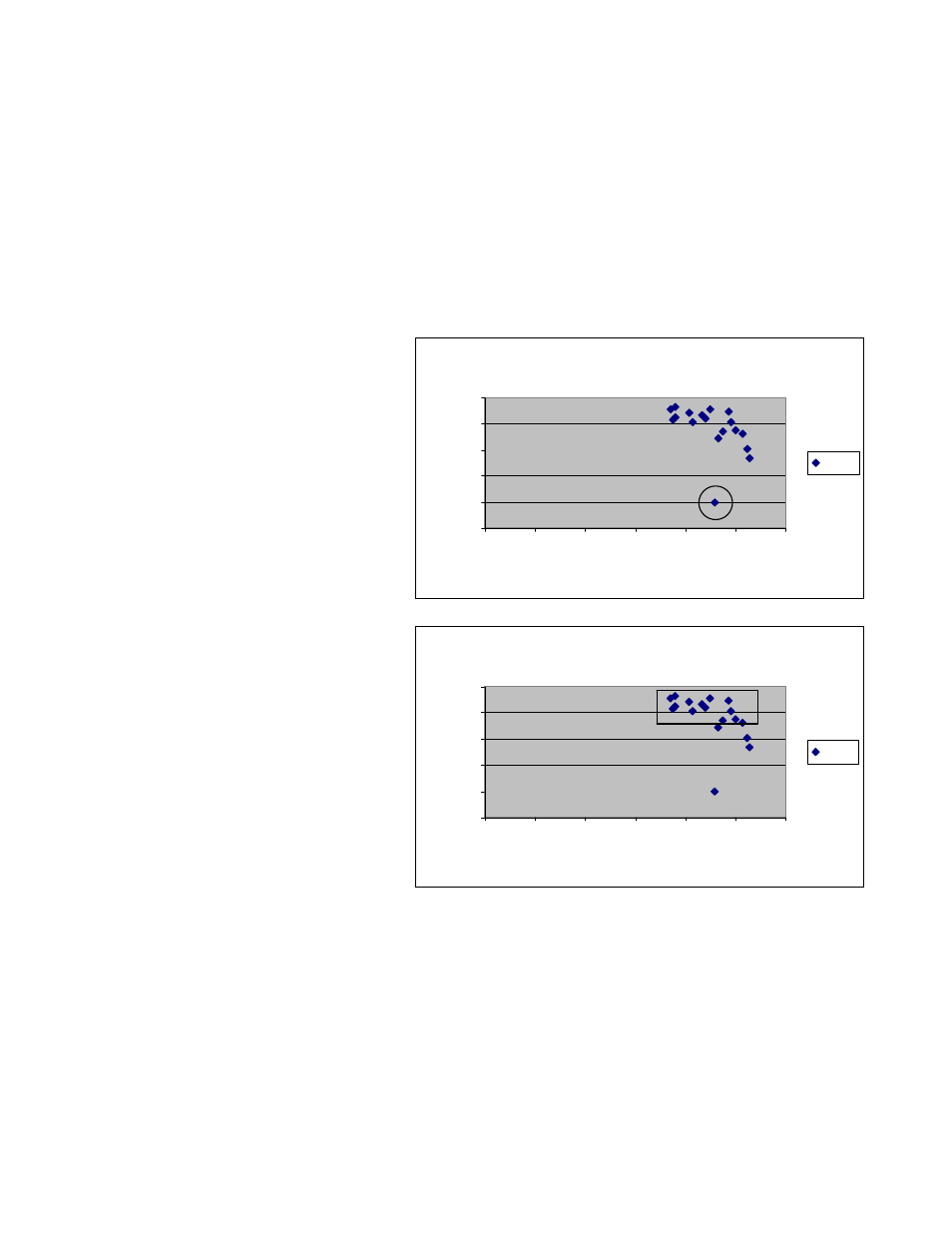

Understanding tolerances requires an

understanding of the weld lobe. Restated

simply, a weld lobe is the range for any

welding parameter in which a high-

quality weld can be made. A weld lobe

is typically defined by destructively

testing welds and then examining the

corresponding weld data to determine

quality limits.

An example of collected weld data is

shown in figure 3-1. In this graph, the

diamond shapes represent welds made.

The horizontal axis is the weld Current

(measured in KA) and the vertical axis

is Force (measured in lbs.). Although

this particular graph only shows force

and current, all weld parameters can be

toleranced using a Livingston monitor.

The locations of the diamonds show

exactly how much force was used at a

particular current for the displayed weld

set. For example, the circled diamond in

figure 3-1 indicates a weld made with

approximately 9.5 KA of weld current at

895 lbs. of force.

To determine the lobe for this particular data set, each part associated with these welds would be

destructively tested. Suppose that testing revealed that the welds made within a range of about 908 to

914 lbs. of force, with a range of about 7 – 11 KA of current were all good. If a box is drawn to isolate

these ranges, as shown in figure 3-2, the area within that box is the weld lobe. The box itself represents

the tolerance limits, or the limits of the range in which good (high-quality) welds can be made. A

master is what provides the monitor with a weld signature that is within the weld lobe. Tolerances are

what define the boundaries of that box. Once a master is created and toleranced, Livingston monitors

will reject any welds that have fallen outside of the box (out of tolerance), while any welds inside the

box (within tolerance) will be accepted.

Weld Data: Current vs. Force

890

895

900

905

910

915

0

2

4

6

8

10

12

Current Rms in KA

Force in Lbs.

force

Figure 3-1 Weld data showing Force and Current

Example of a Weld Lobe

890

895

900

905

910

915

0

2

4

6

8

10

12

Current Rms in KA

Force in Lbs.

force

Figure 3-2 Example of a Weld Lobe for Force