Recommendations for producing quality welds – Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 17

0428-INS-400 Rev. E

1- 9

Recommendations for Producing Quality Welds

To produce high quality welds consistently, follow these tips:

1. Be sure that the electrodes you are using are suitable for the job.

2. Use standard electrodes whenever possible.

3. Select an electrode tip diameter suited to the thickness of the stock being welded.

4. Make use of flow indicators for viewing and assuring proper cooling water flow through the

electrodes (typically, 1.5 gallons per minute).

5. Ensure that the internal water cooling tube of the holder projects into the tip water hole to within ¼

inch of the bottom of the tip hole.

6. Adjust the internal water-cooling tube of the holder to the appropriate height when switching to a

different length tip.

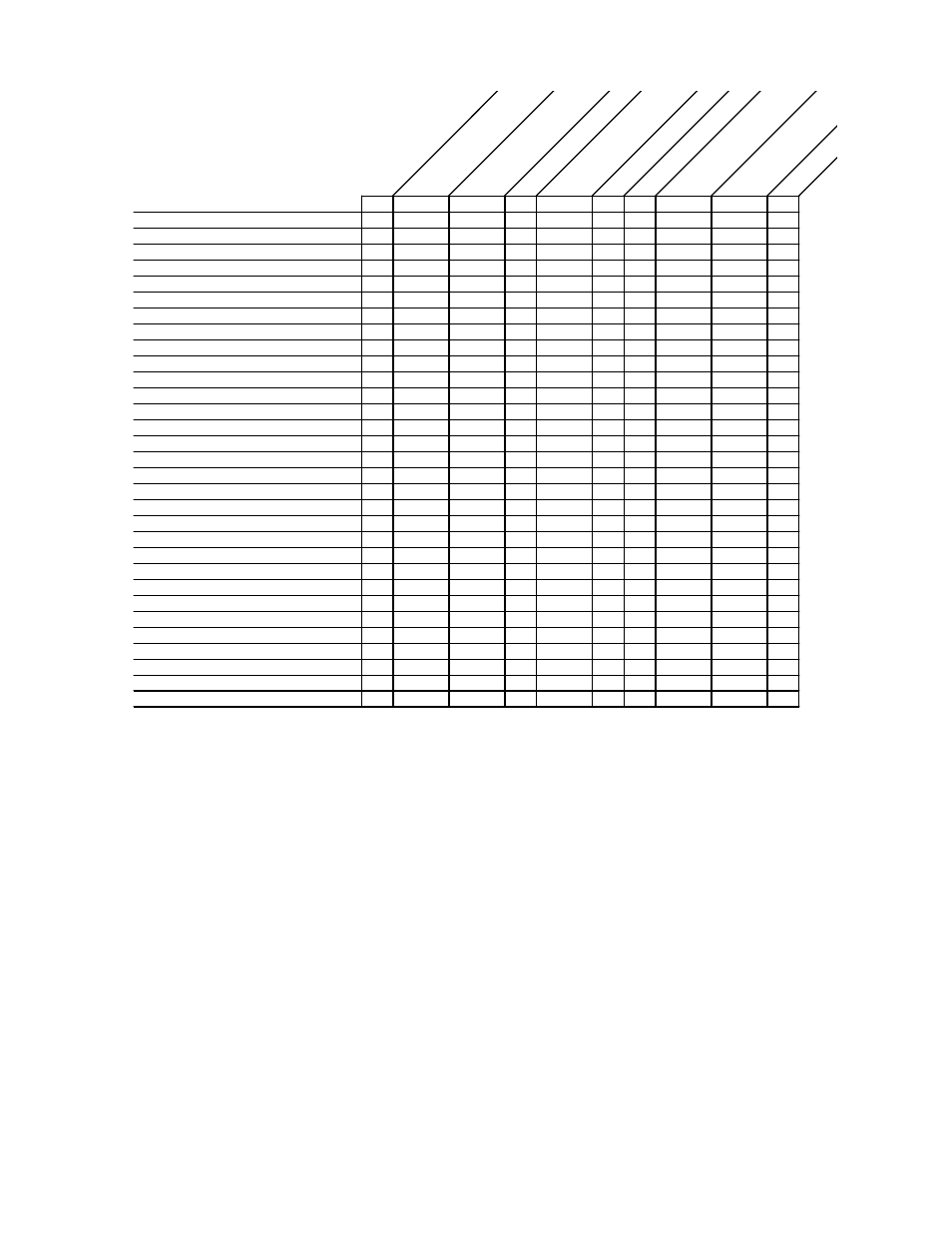

Exce

ss

In

den

ta

tio

n

Ele

ctr

od

e

Mu

shro

om

in

g

Un

dersized

We

ld

Nu

gg

et

Off

set

Weld

Nug

ge

t

Mis

sh

ap

en

We

ld

Nu

gg

et

Ex

pl

us

io

n a

t Surf

ac

e

Exp

uls

io

n a

t I

nt

erf

ace

Cra

cked

o

r Po

or Wel

d

Nugg

et

Di

sc

ol

ored

We

ld

Nu

gg

et

No

Weld

Weld Force Too High

X

X

X

X

Weld Current Too High

X

X

X

X

X

Weld Time Too Long

X

X

X

X

X

Weld Force Too Low

*

X

X

X

X

Weld Current Too Low

X

X

Weld Time Too Short

X

X

Electrode Face Too Small

X

X

X

X

X

Electrode Face Too Large

X

X

Insufficient Electrode Cooling

X

Electrode Allow Too Soft

X

Electrodes Not Flat & Parallel

X

X

X

Electrodes Misaligned

X

X

Poor Fit Up

X

X

X

X

X

X

X

Poor Heat Balance

X

X

Weld Spacing Too Close

X

X

Weld Too Close To Edge of Part

X

X

X

Dirty Material

X

X

X

X

X

Metallurgy of Material

X

X

Squeeze Time Too Short

X

X

Poor Follow-Up

X

X

X

X

No Speed Regulator On Cylinder

X

Poor Pressure Regulation

X

Hold Time Too Short

X

Transformer Tap Set To Off

X

No Weld Switch(es) In No Weld

X

Pressure Switch Open

X

Temperature Limit Switch Open

X

Electrodes Do Not Contact Work

X

Insulated Electrodes/Holders

X

Shunt Path In Secondary

X

X

Excess Ferrous Material In Throat

X

X

Emergency Stop Switch Open

X

* If Weld Force is too low, excess heating of the material surface may cause excess indentation.

Figure 1-3 Chart of weld defects and possible causes