Problem possible cause or symptom possible fix – Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 123

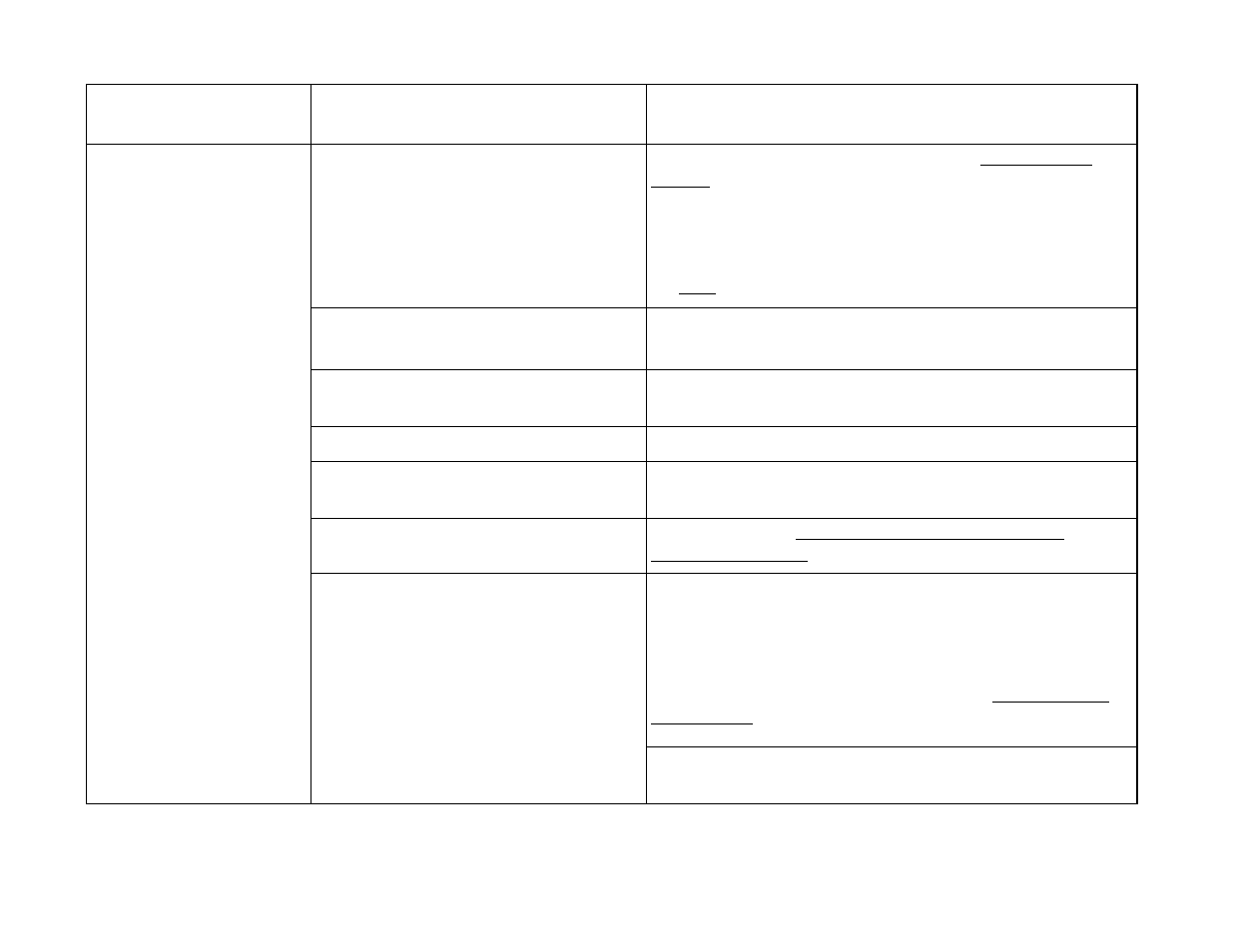

PROBLEM

POSSIBLE CAUSE OR

SYMPTOM

POSSIBLE FIX

Sensor is reading outside of usable range

(window).

Zero the displacement. (Refer to Chapter 8, Calibrating the

Sensors or Supplementary Procedure, if applicable). If

monitoring more than 1 specific weld with the weld monitor

(e.g., weld gun shuttles or moves to multiple locations when

welding), verify that the initial and final stack-ups are within

the displacement window for each weld being made. (Refer to

the FAQ for more information about the displacement window).

Mechanical problems: loose displacement

brackets or loose tooling.

Check the tooling and brackets for looseness or mechanical

slop. Check for loose electrodes. Repair as necessary.

Welds are being made with missing parts. Check welded parts for missing parts, nuts, etc. Check nut

feeder.

Mechanical binding.

Check for mechanical binding.

Process timing has changed. Weld head is

extending too late or retracting too soon.

Check for mechanical binding. Check for PLC program

changes.

Sensor failure.

Refer to Section 3, Trouble With Displacement Sensor,

Readings or Channel.

Inspect sensor cable for physical damage. A cable that is

deformed, severed, partially severed, shredded, abraded and/or

has bare wires showing may be suspect. Disconnect sensor

cable from the weld monitor and replace. Try to reposition

cable new to avoid recurring damage. Spiral wrap or guards will

also help to protect cable. Refer to Section 6, Possible Sensor

Cable Failure.

EVERY WELD IS

REJECTED: The Weld

Summary screen indicates

that any or all Displacement

parameters (Initial

Thickness, Final Thickness,

Setdown, Expansion) are

out of tolerance.

CONT’D

Sensor cable failure.

Inspect electrical connections for damage, poor connections

and/or corrosion. Replace connectors and/or cable.

10-7

0455

-INS-4

00

R

ev

. C