Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 54

0433-INS-400 Rev. E

6-8

• Accept Status

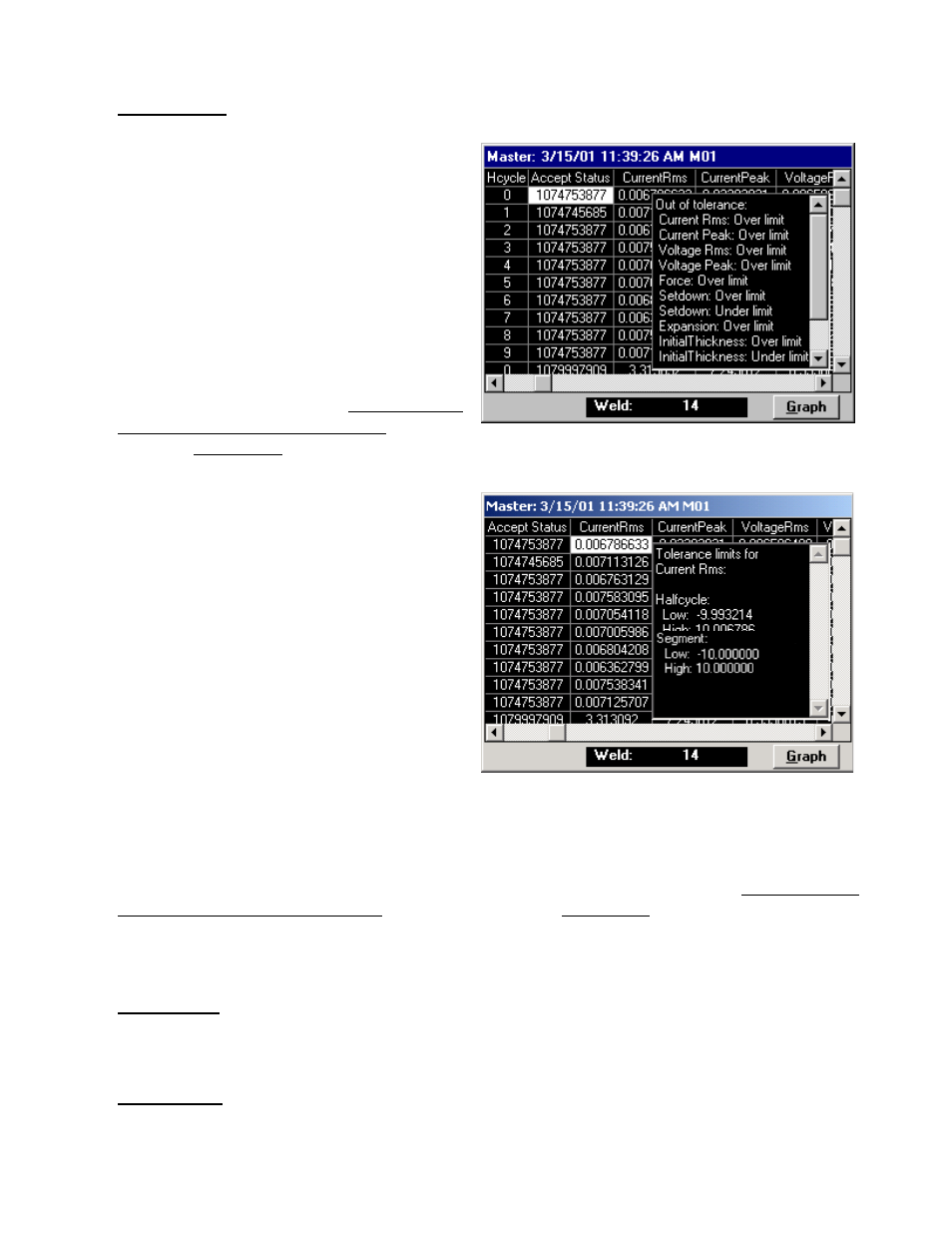

The Accept Status field will be zero if the

weld was within all specified tolerances in the

master. If the Accept Status field is not zero,

then at least one parameter of the weld was

outside of the master tolerance limits.

Use the arrow keys to scroll through the rows

(data records) and columns (data parameters).

To determine the parameters that were out of

tolerance in a given row (data record),

highlight the Accept Status, and press the

SELECT button. A pop-up window will

display the failed parameters, as shown in

figure 6-13. Refer to the topic Identifying and

Interpreting Accept Status Codes (Chapter

11) in the Appendices of this manual for more

information about the Accept Status codes.

If the SELECT button is pressed while an

individual data record is highlighted, the pop-

up window will display the Halfcycle, and

Segment High and Low Tolerance limits for

that parameter, as shown in figure 6-14.

If a master was NOT used to qualify this weld

then no limits will be displayed.

The tolerance limits displayed are taking from

the master. In figure 6-14 the Master weld

data (for this halfcycle) for CurrentRms is

0.006786 and the tolerances are set to +/-10

(relative tolerancing) in the master. The high

tolerance limit is 0.006786 + 10 = 10.006786.

The Low tolerance limit is 0.006786 - 10 = -

9.993214.

Use ESCAPE or Arrow Keys to close the pop-up window. Refer to the topic Identifying and

Interpreting Accept Status Codes (Chapter 11) in the Appendices of this manual for more

information about the Accept Status codes.

• CurrentRms

The RMS (Root-Mean-Square) current in a halfcycle, or average RMS current for a segment or

weld.

• CurrentPeak

The peak (positive or negative) current in a halfcycle, or the peak current in a segment or weld.

Figure 6-13 Pop-up window displaying all parameters

that were out of tolerance

Figure 6-14 Pop-up window displaying tolerance

limits for selected parameter