Problem possible cause or symptom possible fix – Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 125

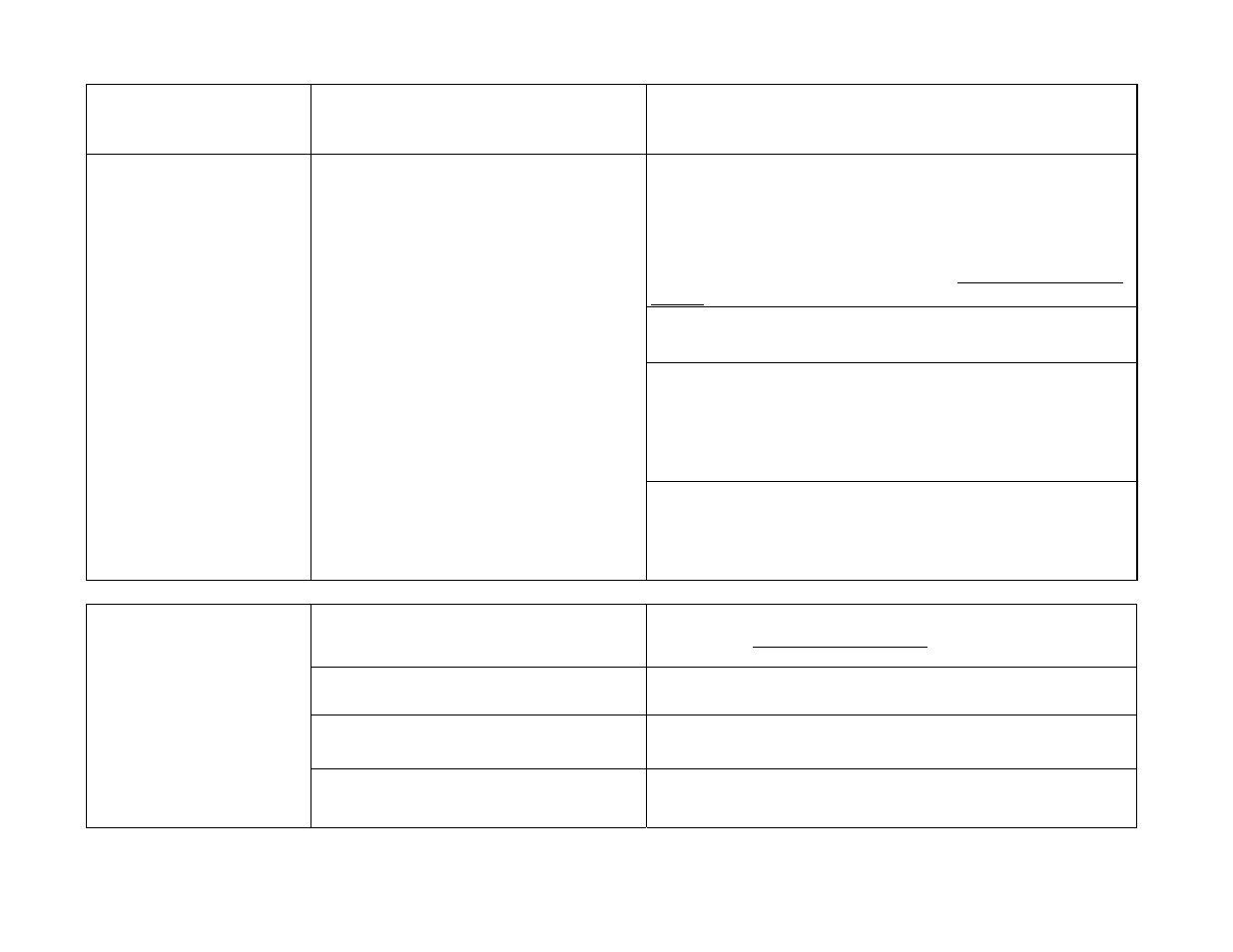

PROBLEM

POSSIBLE CAUSE OR

SYMPTOM

POSSIBLE FIX

Inspect sensor cable for physical damage. A cable that is

deformed, severed, partially severed, shredded, abraded and/or

has bare wires showing may be suspect. Disconnect sensor

cable from the weld monitor and replace. Try to reposition new

cable to avoid recurring damage. Spiral wrap or guards will also

help to protect cable. Refer to Section 6, Possible Sensor Cable

Failure.

Inspect electrical connections for damage, poor connections

and/or corrosion. Replace connectors and/or cable.

Use the Input Monitor screen to observe the force channel

readings. Try flexing different areas of the sensor cable looking

for any area that causes the readings on the Input Monitor to

"jump". Replace the cable if flexing any part of it causes

intermittent readings.

EVERY WELD IS

REJECTED: The Weld

Summary screen indicates

that Force Parameters are

out of tolerance.

CONT'D

Sensor cable failure.

Disconnect the sensor cable from the weld monitor & sensor

and then using Livingston sensor cable documentation, check

continuity of all connections within the cable. Repair or replace

cable as necessary.

Calibration has changed.

Inspect and re-enter toroid calibration factor if necessary (Refer

to Chapter 8, Calibrating the Sensors).

Tolerances are set improperly.

Adjust the tolerances.

Voltage lead failure or poor connections.

Inspect the voltage leads for severed or abraded wires, or poor

connections and repair as necessary.

EVERY WELD IS

REJECTED: The Weld

Summary screen indicates

that Current, Voltage,

Energy, Resistance or

Conduction Angle

Parameters are out of

tolerance.

Weld process has changed due to shunt,

tooling change or tooling failure.

Check welded parts for missing parts, nuts, etc. Check nut

feeder. Inspect the shunts and tooling.

10-9

0455

-INS-4

00

Re

v.

C