Summary – Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 45

0432-INS-400 Rev E.

5- 11

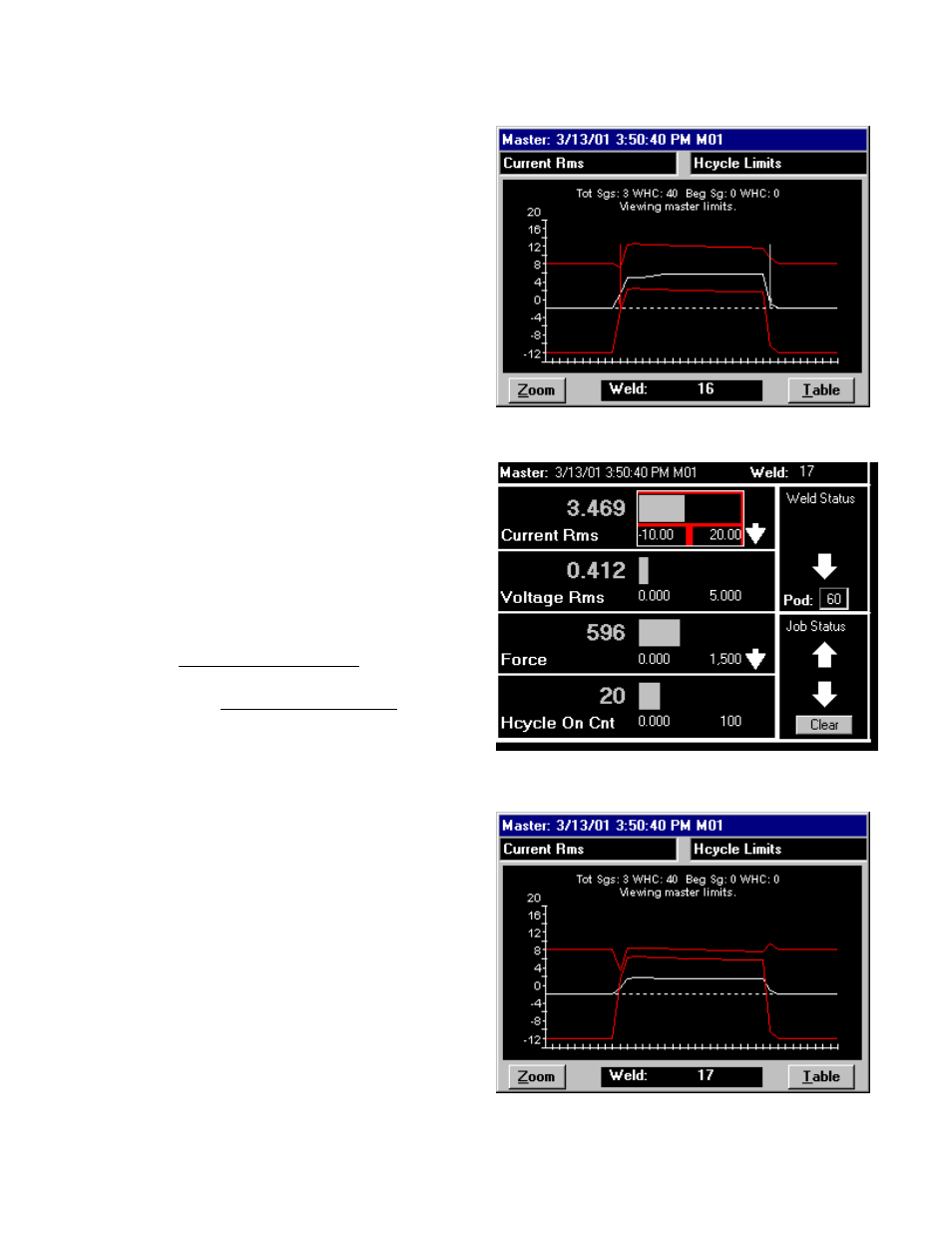

Figure 5-20 Halfcycle Summary for ACCEPTED

weld

Figure 5-21 Main program screen displaying a

REJECTED weld (Current Rms, etc. too low)

Figure 5-22 Halfcycle Summary for REJECTED

weld

7. Decrease the heat on your weld schedule by 20.

(If your schedule is set for 45% heat, lower it to

25% heat). ESCAPE to the main screen and

make a weld.

8. The Weld Status box should display flashing

arrows, indicating a REJECTED weld, as shown

in figure 5-21. Go to the Halfcycle Summary

screen. It should look similar to figure 5-22.

Notice that the Current Rms line is below the

lower tolerance boundary, causing a

REJECTED weld.

Summary

Remember, this guide is intended as an example

only— the creation of masters and tolerances for

individual weld processes will vary. Please refer to

Chapter 6, WMS Reference Guide for a complete

description of all functions in the WMS program, or

use Chapter 10, Troubleshooting Guide for more

information about mastering.