Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 138

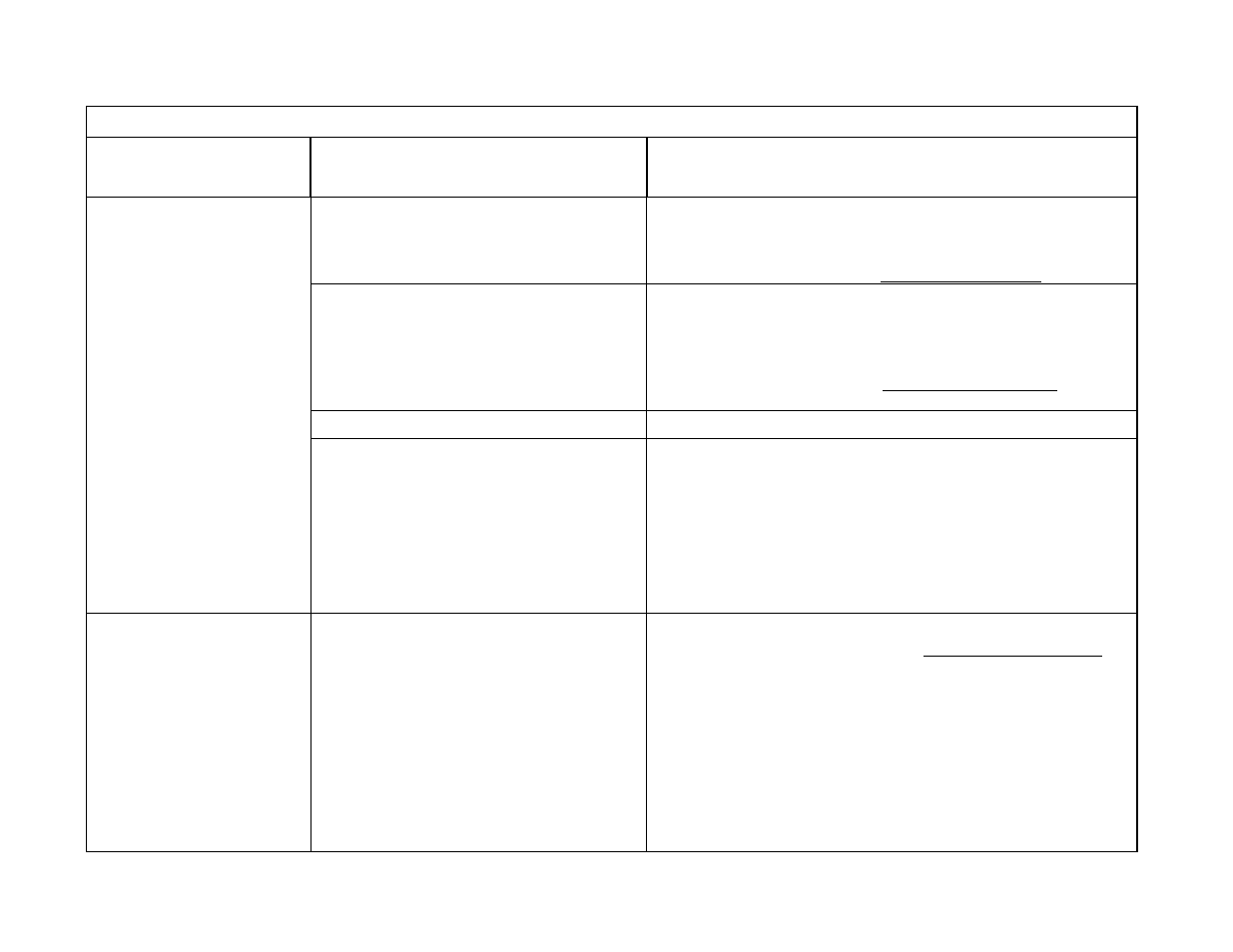

5. TROUBLE WITH VOLTAGE LEADS, READINGS OR CHANNEL

PROBLEM

SYMPTOM OR POSSIBLE

CAUSE

POSSIBLE FIX

Voltage leads are broken.

Inspect for damage, use an ohmmeter to check for high

resistance, flex and manipulate leads to see if readings change,

indicating an intermittent connection. Replace leads if

necessary. Refer to Chapter 7, Installing the Sensors.

Calibration has changed.

Verify calibration by disconnecting leads from electrodes and

connecting to a 1.5V flashlight battery, also connect a DMM,

the reading on the multimeter should match the calibrated

reading on the Input Monitor screen. Recalibrate voltage if

necessary (Refer to Chapter 8, Calibrating the Sensors).

Voltage leads are not connected properly. Inspect

electrical

connections for poor connections or corrosion.

CALIBRATED

VOLTAGE SIGNAL IS

READING HIGHER OR

LOWER THAN

NORMAL OR

CALIBRATED

VOLTAGE SIGNAL IS

INDICATING A

FROZEN (static)

READING

Sensor Cable or weld monitor failure.

Inspect sensor cable for physical damage. A cable that is

deformed, severed, partially severed, shredded, abraded and/or

has bare wires showing may be suspect. With the flashlight

battery connected flex and manipulate leads to see if the

calibrated readings “jump” or change. If so disconnect sensor

cable from the weld monitor and replace with a spare sensor

cable. Try to reposition the new cable to avoid recurring

damage. Spiral wrap or guards will also help to protect cable.

FROZEN A/D READING

(VOLTAGE ONLY): The

Input Monitor indicates a

constant (static) A/D

reading for voltage. This

value never changes; the

other sensor channels

appear to be working and

the A/D values for these

channels are

changing/updating.

Weld monitor has a problem with the

voltage channel.

A static reading may indicate a problem with the weld monitor

voltage channel. Refer to Section 8, Trouble With Hardware.

10-22

04

55

-IN

S-

40

0 Re

v. C