Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 121

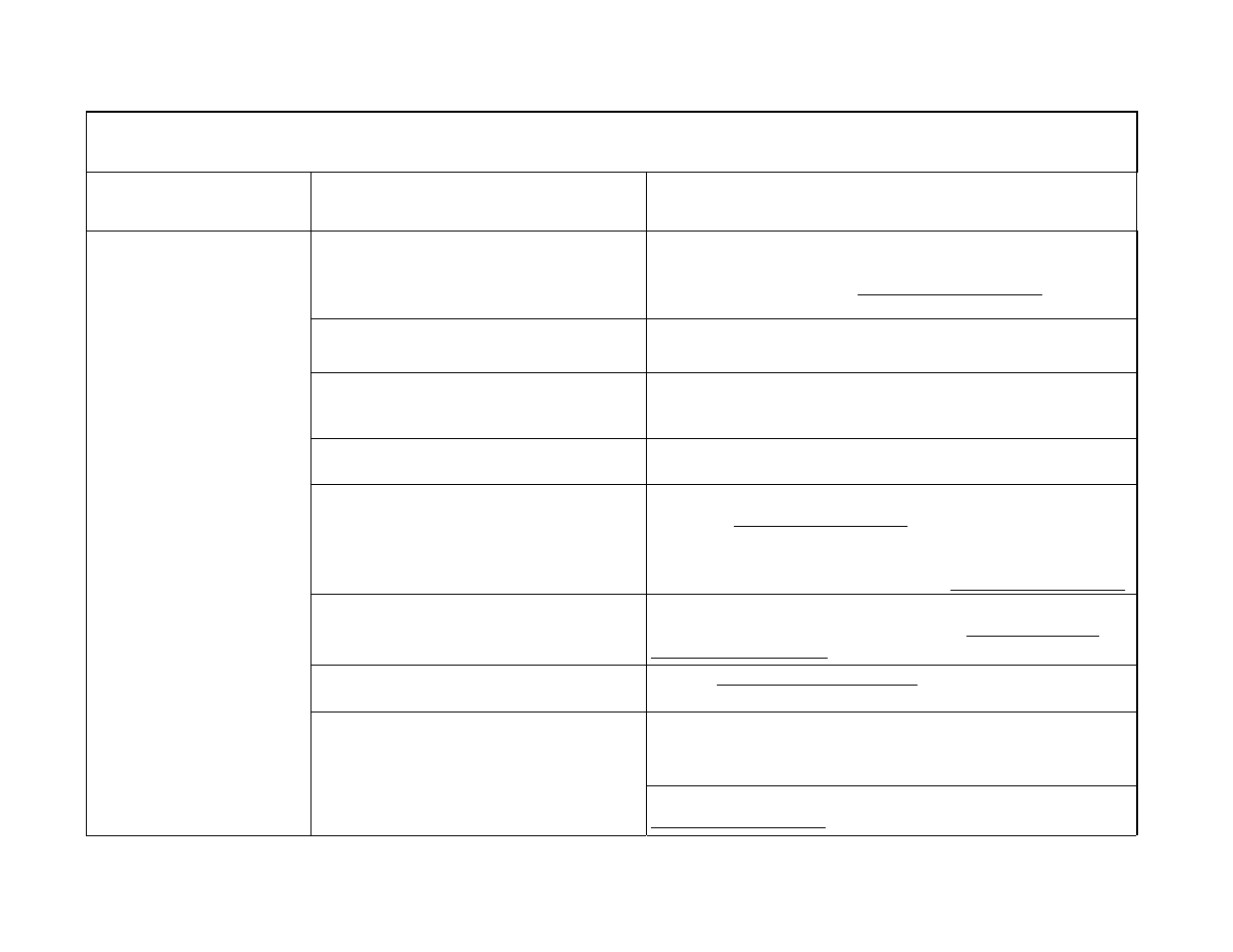

1. SOME OR ALL WELDS ARE REJECTED, NOT CATCHING FAULTY WELDS, WELD

COUNT NOT INCREASING

PROBLEM

POSSIBLE CAUSE OR

SYMPTOM

POSSIBLE FIX

No Master or Master tolerance limits have

been created. It is possible that they were

made, but not updated.

Check to see if "No Master" is displayed on the Main Program

screen. If so, create a new Master or new Master tolerance

limits. (Refer to Chapter 5, WMS Quick Start Guide or

Supplementary Procedure, if applicable).

Masters are not enabled.

Go to the General Setup menu and set Masters Enabled to

Yes.

Weld schedule has changed.

Change weld schedule back to what it was when the Master was

created, create a new Master, or adjust Master Tolerance Limits

for the new schedule.

Tolerances are set improperly.

Adjust the tolerances.

Calibration has been changed.

Check calibration and recalibrate sensor if necessary (Refer to

Chapter 8, Calibrating the Sensors). Note: If an Export Setup

was performed the last time this sensor was properly calibrated,

an Import Setup may be performed to reload the saved

calibration settings. Refer to Chapter 6, WMS Reference Guide.

Incorrect Bin Select.

Depending on system configuration, the Bin Select may be

Internally or Externally selected. Refer to Trouble With Bin

Select or Accept/Reject. Section 7 of this Chapter.

No welds are being detected.

Refer to Trouble With Weld Count.

Inspect sensor for physical damage. Inspect electrical

connections for poor connections or corrosion. Replace sensor

if any damage is found.

EVERY WELD IS

REJECTED: The weld

summary screen indicates

that almost every parameter

is rejecting.

Sensor failure.

Replace the sensor and Re-calibrate. (Refer to Chapter 8,

Calibrating the Sensors for more information about this screen).

10-5

0455

-INS-4

00

R

ev

. C