Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 43

0432-INS-400 Rev. E

5-9

5. If for some reason your weld rejected, try making more welds to see if any accept. If the welds

continue to reject, review the failed parameters and skip ahead to the tolerancing section of the

WMS quick start guide. Adjust master tolerances until welds are accepted and continue with the

following steps to make a rejected weld.

Making a rejected weld

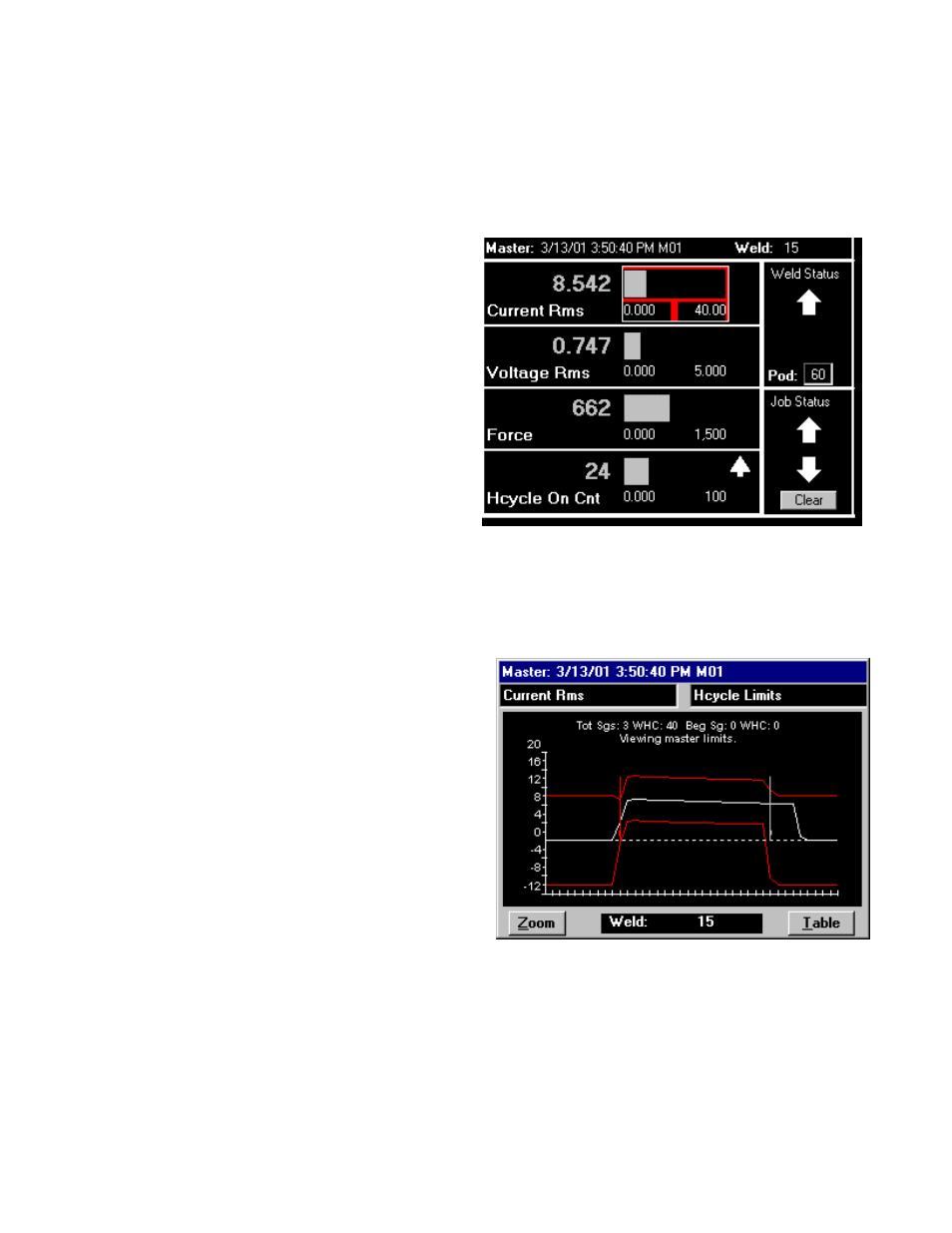

Now we will deliberately reject a weld and see

what the resulting halfcycle data looks like. We'll

use an increased halfcycle count as an example.

1. ESCAPE to the main program screen.

2. Increase the weld cycle count by 2 on your

weld controller.

3. Make a weld using the new weld schedule and

observe the monitor screen. You should see a

blinking arrow in the Weld Status box, as

shown in figure 5-16. If one of your displayed

parameters is Hcycle On Cnt, you'll also see a

small blinking arrow next to the bar graph.

4. Go to the Halfcycle Summary screen. It should look something like figure 5-17.

Notice that although the line representing

Current Rms has remained within the tolerance

boundaries, it has extended past the Weld

segment boundary. Because of the 4 added

halfcycles in the weld schedule, this weld did

not match the master (the master was made

without the extra 2 cycles) and as a result was

not passed (REJECTED).

5. Remove the two additional cycles from your

weld schedule before proceeding.

Figure 5-16 Main program screen showing

REJECTED weld

Figure 5-17 Halfcycle Summary of REJECTED weld