Problem possible cause or symptom possible fix – Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 134

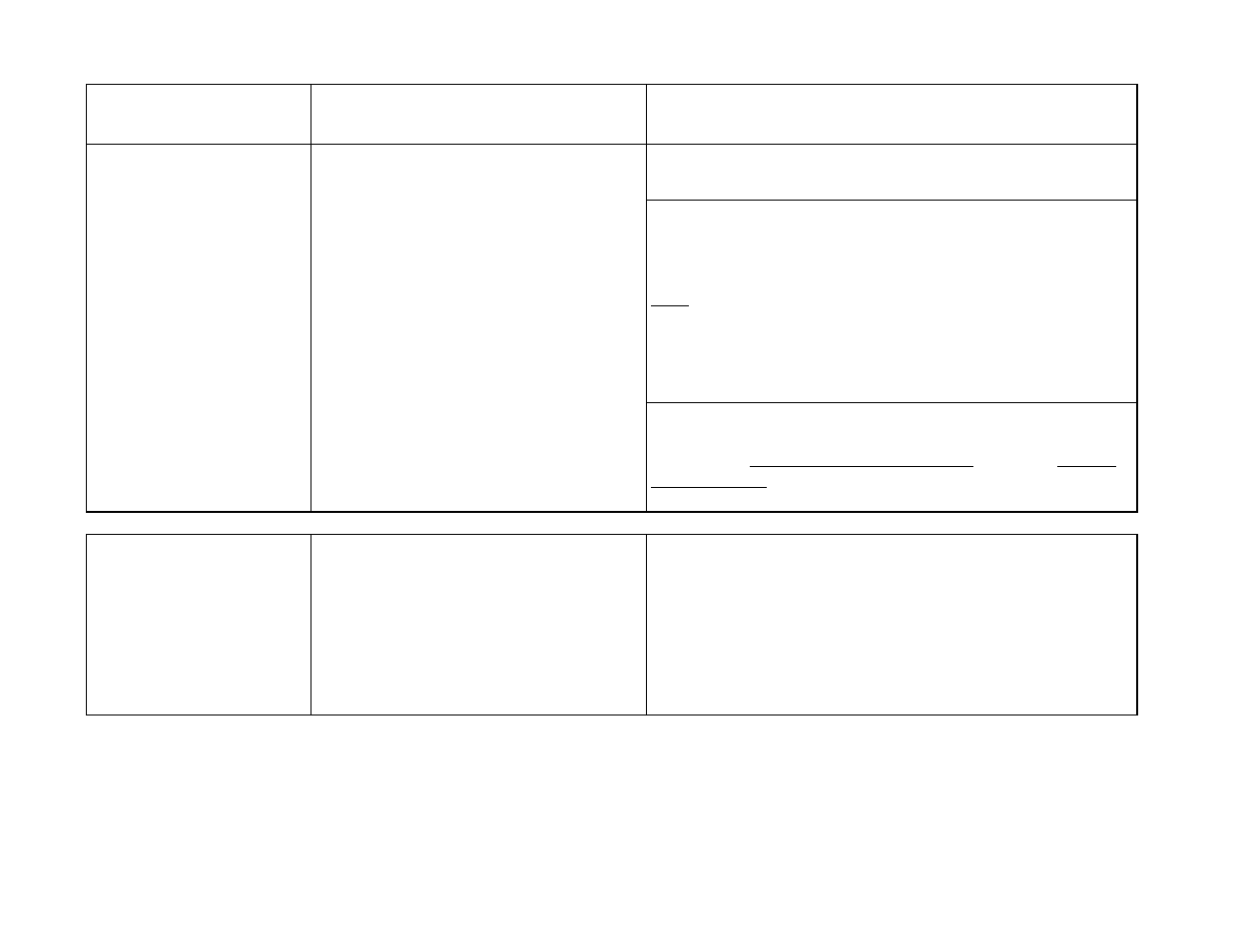

PROBLEM

POSSIBLE CAUSE OR

SYMPTOM

POSSIBLE FIX

Inspect electrical connections for damage, poor connections

and/or corrosion. Replace connectors and/or cable.

Use the Input Monitor screen to observe the displacement

channel readings. Mechanically disconnect one end of the

sensor and slowly extend/retract until you are reading within the

'window' of the displacement channel. (Refer to Chapter 9,

FAQ for additional information about the displacement

window). Try flexing different areas of the sensor cable looking

for any area that causes the readings on the Input Monitor to

"jump". Replace the cable if flexing any part of it causes

intermittent readings.

CALIBRATED

DISPLACEMENT

SIGNAL IS INDICATING

A FROZEN (static)

READING

CONT'D

Sensor Cable or weld monitor failure.

CONT’D

If the displacement window cannot be found then the sensor OR

the sensor cable may be failing. To check the sensor cable, refer

to Section 6, Possible Sensor Cable Failure or refer to Trouble

With Hardware. If the cable and weld monitor appear to be

OK, replace the sensor.

FROZEN A/D READING

(ALL): The Input Monitor

indicates a constant (static)

A/D reading for the

displacement sensor. This

value never changes; the

other sensor channels do not

change or update either.

Weld Monitor problem

If other channel readings are not changing, the data may not be

updating. Shutdown and Restart the weld monitor. If problem

persists contact Livingston Service.

10-18

04

55

-IN

S-

40

0R

ev

. C