Accepting / rejecting welds – Dr. Livingstone, I Presume WELDWISE 2400 User Manual

Page 42

0432-INS-400 Rev. E

5-8

Accepting / Rejecting Welds

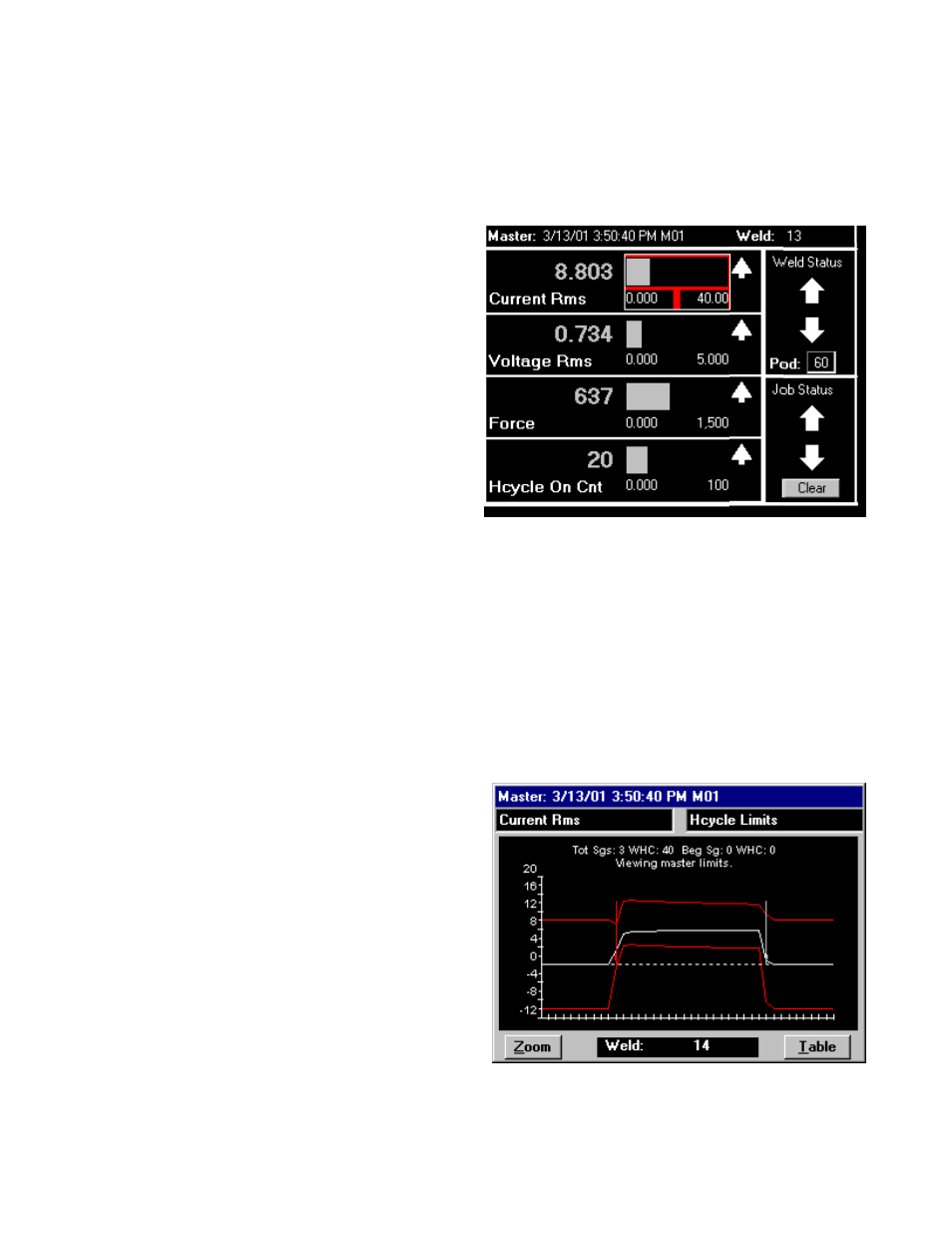

Once a master has been created and updated, the monitor has a basis on which to compare subsequent

welds. If all parameters fall within the master tolerance limits, the weld is accepted by the monitor. If

any of the parameters fall outside of the master tolerance limits, the weld is rejected by the monitor.

This section will demonstrate an accepted weld

and a rejected weld.

Making an accepted weld

1. ESCAPE to the main program screen.

2. Make another weld. Notice that the newly

created master is displayed in the top left,

indicating that the weld was compared against

this master, as shown in figure 5-14. Ideally

this weld should have accepted and a check

mark should be displayed in the Weld Status

box. If there are flashing arrows in the Weld

Status box, then weld rejected for some

reason. Either the weld was rejected because

the master tolerances are set too tightly, or

either the master weld or the last weld made

was not characteristic of a typical weld for this process.

3. Go to the Weld Summary screen and look at the Accept Status for the weld you just made (the

most recent weld will be at the top). An Accept Status of 0 indicates that the weld was accepted. If

the weld was rejected, highlight the Accept Status number and press the SELECT key to see what

parameters failed.

4. Go to the Halfcycle Summary Screen to graphically compare the halfcycle data with the master

tolerance limits. Change the parameter in the top left box to Current Rms and the parameter in the

top right box to Hcycle Limits. Your screen

should now look similar to figure 5-15.

The thin vertical arrows pointing down separate

the three default segments (Pre-weld, Weld and

Post-weld) of the weld process. The upper and

lower horizontal lines represent the default

tolerances assigned to the master. The middle

line represents the weld signature for the weld

number at the bottom of the screen. As you can

see, the parameter Current Rms was within the

tolerance defaults of this master. For the weld

to be accepted, all

parameters must be within

the master tolerance limits.

Selecting different parameters in the upper left

box will allow you to compare all parameters

with the master tolerance limits.

Figure 5-14 Main program screen with new master

date/time stamp displayed

Figure 5-15 Halfcycle Summary, Current Rms

shown with Halfcycle Limits