Rockwell Automation 1441-PEN25-Z Enpac 2500 Data Collector User Manual

Page 258

258

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Chapter 10

Run Up/Coast Down Application

Use the descriptions in this table to help you configure the parameters in the Run

Up/Coast Down Setup screen.

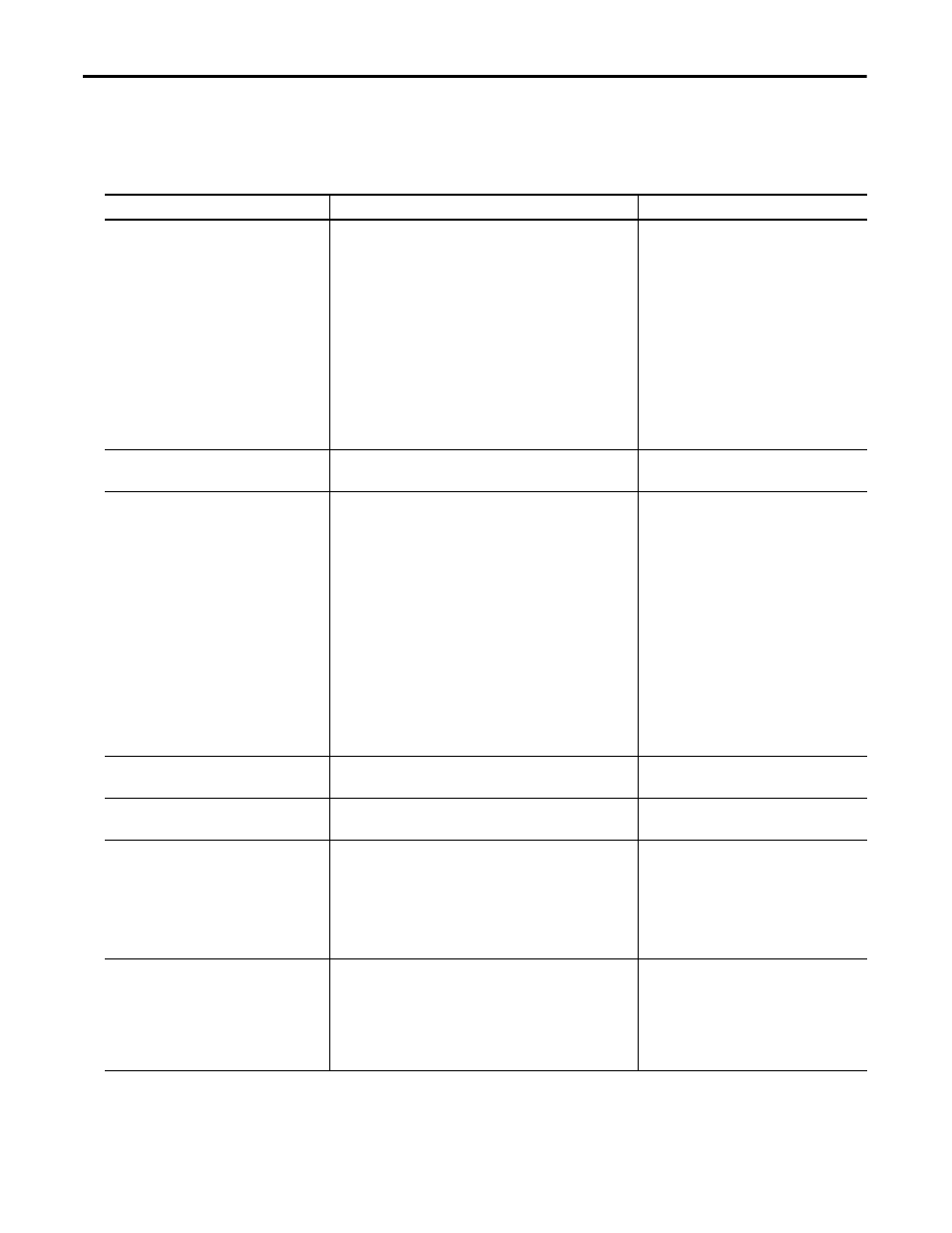

Table 44 - Run Up/Coast Down Setup Parameters

Parameter Name

Description

Values/Comments

Transducer

Type of sensor used on channel 1 of the Enpac 2500.

The sensor type determines available options and engineering units

for subsequent setup fields.

Options:

Accel ICP (g) (default)

Accel (g)

Accel ICP (m/s

)

Accel (m/s

)

Vel ICP (mm/s)

Vel (mm/s)

Vel ICP (ips)

Vel (ips)

Disp (mils)

Disp (um)

Volts AC

User (EU)

Sens (mV/EU)

The transducer sensitivity in millivolts (MV) per engineering units

(EU).

1…2000 (mV/EU)

Default value is 50 (mV/EU)

Range (EU)

The expected maximum amplitude range value.

The range should accommodate for unexpected events; if in doubt,

use caution and set the range 10…20 times higher than expected.

Options:

.1 EU

.2 EU

.5 EU

1 EU

2 EU (default)

5 EU

10 EU

20 EU

50 EU

100 EU

200 EU

500 EU

1000 EU

2000 EU

Max M/c Speed

The maximum speed that the shaft will reach in RPM.

Used with Max No Orders to determine the sampling rate.

10…60000 RPM

Default value is 3600 RPM

Max No Orders

The maximum number of shaft orders of interest during analysis.

Used with Max M/c Speed to determine the sampling rate.

1…166

Default value is 32

Mode

The method for initiating the data collection.

• Runup - The data collection starts when the machine speed rises

above Start Spd.

• Coast down -The data collection starts when the machine speed

falls below Stop Spd.

• Manual - Manually start data collection by pressing F4 (Start). No

tachometer signal is required for this mode.

Options:

Runup (default)

Manual

Coastdown

Pulses/Rev

The number of tachometer signal pulses per revolution of the

reference shaft.

To acquire a suitable tachometer signal, the tachometer signal must

be approximately 1.5 volts peak-to-peak. The adverse effect of

excessively short tachometer pulse widths can be addressed by

setting the Max No Order to a higher value to increase the sampling

rate.

.1…1000

Default value is 1

This number can be a multiple or a non-integer to

accommodate for gear ratios and others.