Two plane balancing, Taking the initial vibration measurement – Rockwell Automation 1441-PEN25-Z Enpac 2500 Data Collector User Manual

Page 222

222

Rockwell Automation Publication GMSI10-UM002D-EN-E - August 2012

Chapter 8

Balancing Application

Two Plane Balancing

This section describes the procedure for balancing a machine in two planes.

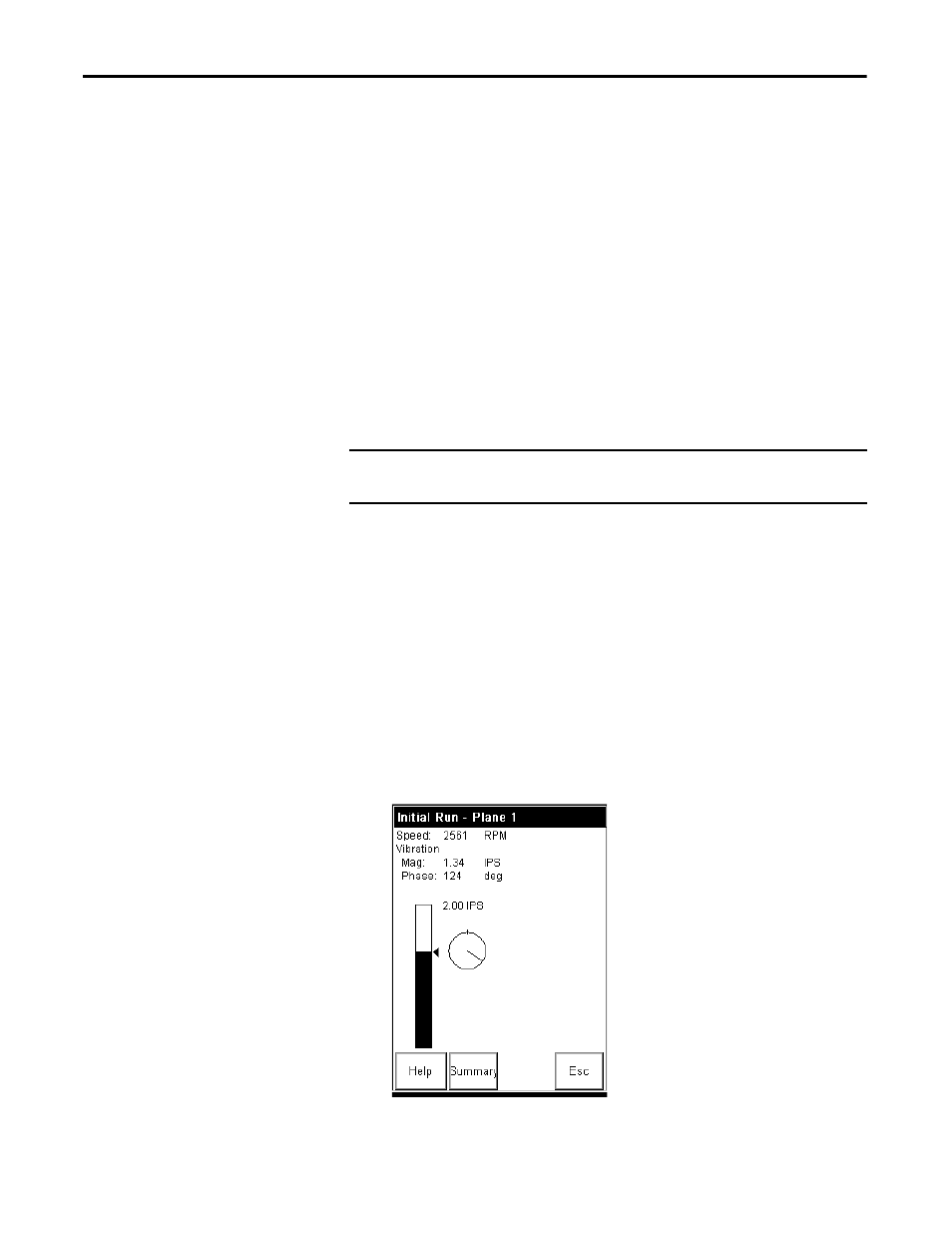

Taking the Initial Vibration Measurement

1.

If you are using an external tachometer, optical tachometer, or strobescope

as the trigger source, then connect the tachometer cable

(Cat. No. EK- 45131) to the POWER/TRIG connector of the data

collector.

2.

Mark the rotor by making a mark on one rotor that will serve as a reference

mark. It is also possible to use an existing mark on the rotor as the reference

mark, such as a key or keyway.

3.

Attach a transducer to a bearing housing in each plane at each end of the

shaft. You must have two identical transducers to complete the two-plane

balancing.

4.

Start the machine and allow it to reach normal running speed.

5.

Press READ/OK to take the initial vibration measurement.

The data collection will begin as soon as the trigger conditions are

satisfied. The data collector automatically measures the speed, vibration,

and phase in the first plane. The values are continually updated on the

screen.

TIP

You can skip this step if you are using the internal Laser Tachometer

as the trigger.

IMPORTANT

If the rotor has multiple positions (vanes or fan blades), the reference mark

must be at one of the blade positions.

TIP

The data collector may ask if the transducer is attached to plane 1.

If the transducer is attached, press F4 (OK).