IAI America RCS3PCR-SS8C User Manual

Page 98

0

11. Maintenance and Inspection

11.7.2

How to Apply Grease to RCS2

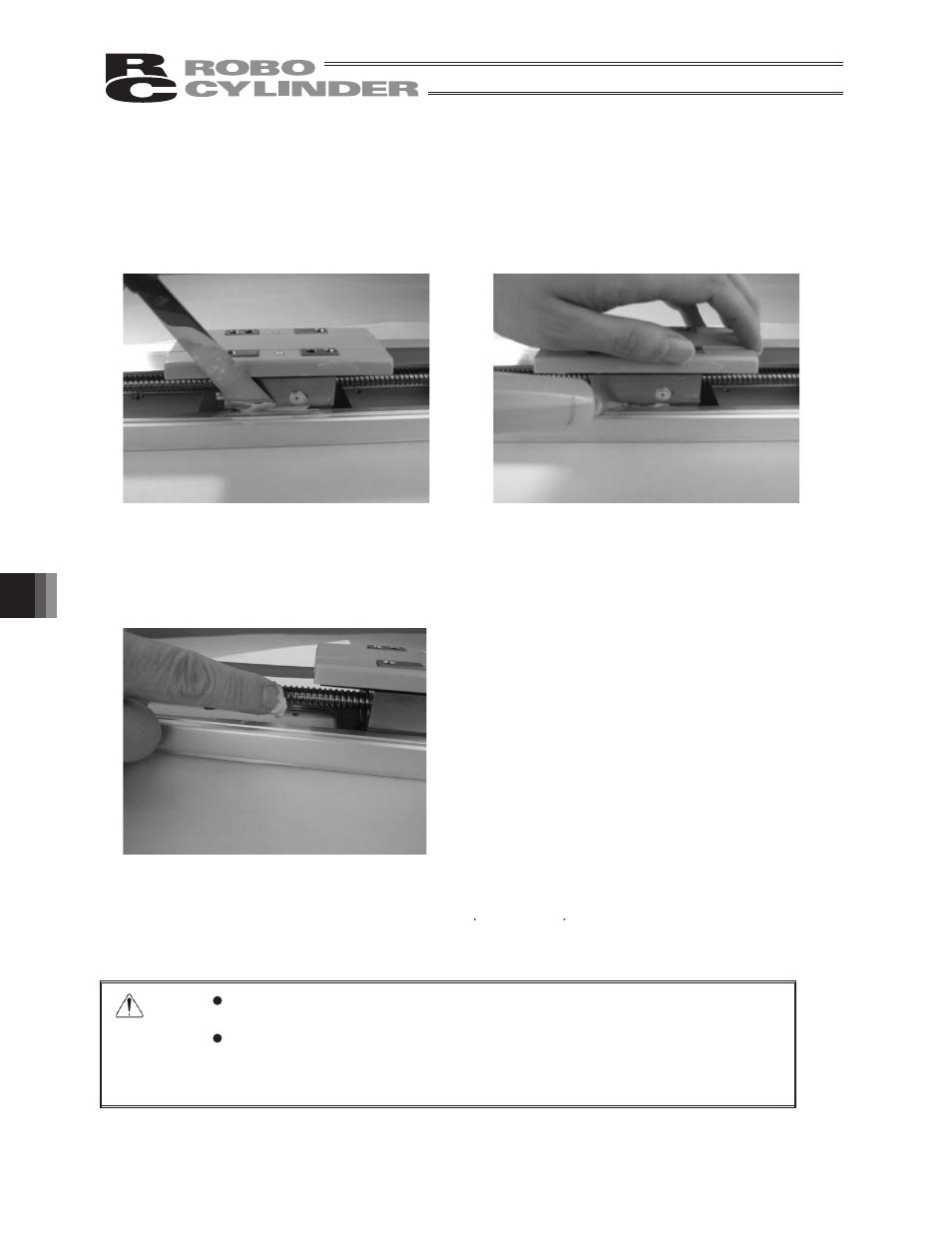

1) When greasing the guide, use a spatula or grease applicator to squeeze or inject grease into the space

between the slider and base, and then move the slider back and forth several times to let the grease spread

evenly.

Apply grease on the guides on both sides.

Remove excess grease.

2) When greasing the ball screw, clean the ball screw, apply grease using a finger, and then move the slider

back and forth several times to let the grease spread evenly.

At this time, be careful not to deform the stainless sheet by accidentally touching the sheet.

Remove excess grease.

3) Install the side covers.

Tightening torque: Thin-head screw M3 x 6 – 87.2 N cm (8.90 kgf cm)

Refer to 3) in 11.5 “Interior Inspection,” for notes on installing the side covers.

Caution:

In case the grease got into your eye, immediately go to see the doctor to get an

appropriate care.

After finishing the grease supply work, wash your hands carefully with water and soap to

rinse the grease OFF.

If the actuator is equipped with a microswitch (optional), carefully install the side

covers so that the switch cables are not pinched.

- RCS3PCR-SA8C RCS3CR-SS8C RCS3CR-SA8C RCS3P-SS8C RCS3P-SA8C RCS3-SS8C RCS3-SA8C RCS2CR-SS8C RCS2CR-SS7C RCS2CR-SA7C RCS2CR-SA6D RCS2CR-SA6C RCS2CR-SA5D RCS2CR-SA5C RCS2CR-SA4C RCS2-SS8R RCS2-SS8C RCS2-SS7R RCS2-SS7C RCS2-SA7R RCS2-SA7C RCS2-SA6R RCS2-SA6D RCS2-SA6C RCS2-SA5R RCS2-SA5D RCS2-SA5C RCS2-SA4R RCS2-SA4D RCS2-SA4C