IAI America RCS3PCR-SS8C User Manual

Page 164

11. Maintenance and Inspection

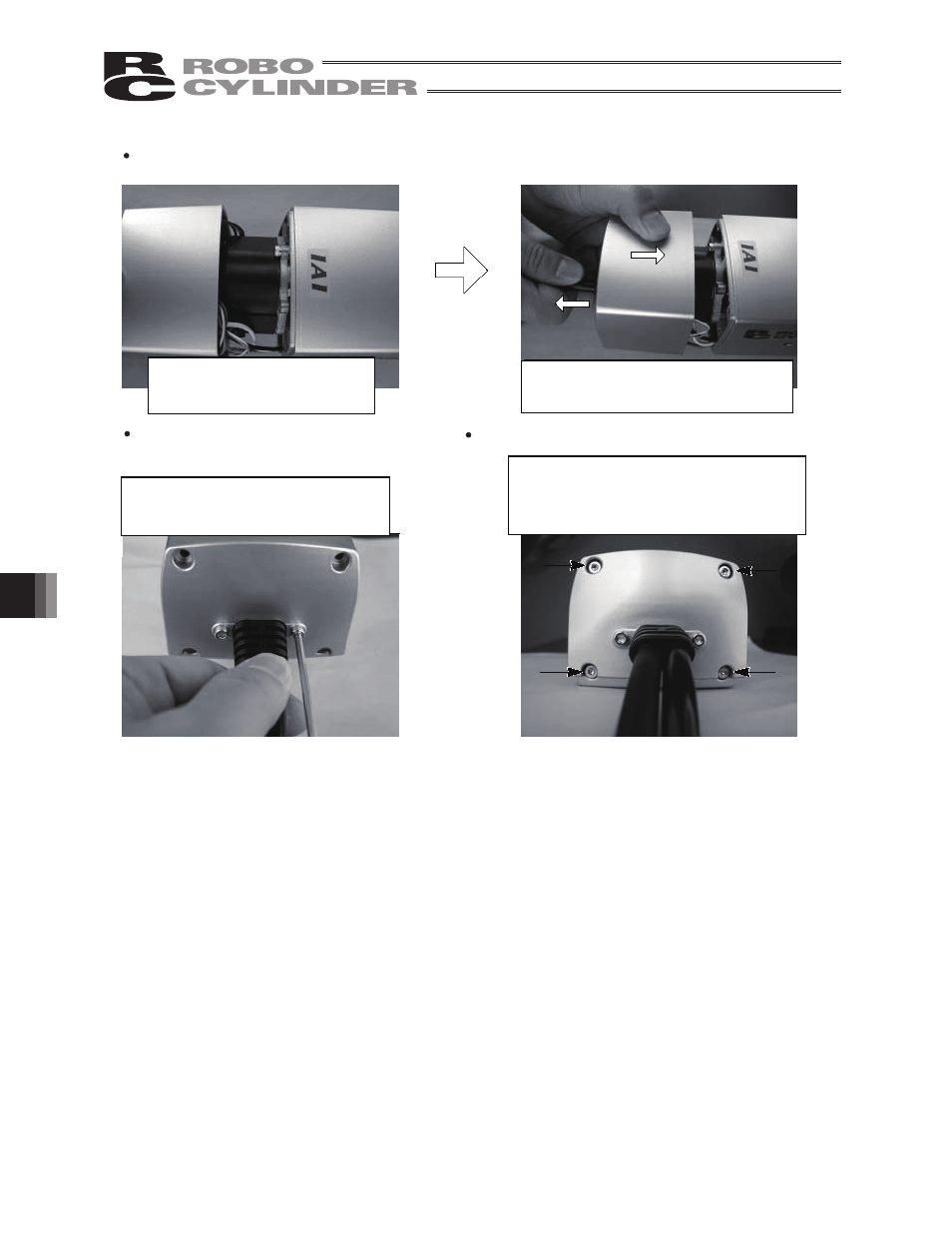

12) Install the motor-end cap.

Carefully push in the motor-end cap by making sure the cables are not pinched.

13) Correct the position deviation.

[Incremental encoder]

[1] Check the home position.

Turn on the controller power.

Use the PC software or teaching pendant to perform homing to check the home position. Repeat homing

several times to confirm that the actuator returns to the same position every time.

[2] Check the amount of position deviation.

The home position may have shifted slightly after the motor replacement.

To check the amount of position deviation, select a desired position number appropriate for checking the

deviation after the motor replacement, perform positioning to the selected position, and measure the

amount of deviation.

[3] Correct the deviation.

If there is a deviation from the initial home position when the SCON controller is being used, make

corrections using home return offset distance of parameter No. 22. If the SSEL or the X-SEL controller is

being used, make corrections using home preset value of the axis-specific parameter

No. 12.

Carefully push in the motor-end

cap by making sure the cables

are not pinched.

Pull out the cable end while pushing in

the motor-end cap.

Tighten the bolts while securely

holding the cable end by hand.

Affix the motor-end cap.

Uniformly tighten the two hexagon

socket-head bolts (M3×8) using an

Allen wrench of 2.5 mm across flats.

Uniformly tighten the two hexagon socket-

head bolts (M3×50) using an Allen wrench

of 2.5 mm across flats.

Tightening torque: 83 N・cm (8.47 kgf・cm)

- RCS3PCR-SA8C RCS3CR-SS8C RCS3CR-SA8C RCS3P-SS8C RCS3P-SA8C RCS3-SS8C RCS3-SA8C RCS2CR-SS8C RCS2CR-SS7C RCS2CR-SA7C RCS2CR-SA6D RCS2CR-SA6C RCS2CR-SA5D RCS2CR-SA5C RCS2CR-SA4C RCS2-SS8R RCS2-SS8C RCS2-SS7R RCS2-SS7C RCS2-SA7R RCS2-SA7C RCS2-SA6R RCS2-SA6D RCS2-SA6C RCS2-SA5R RCS2-SA5D RCS2-SA5C RCS2-SA4R RCS2-SA4D RCS2-SA4C