IAI America RCS3PCR-SS8C User Manual

Page 112

0

11. Maintenance and Inspection

102

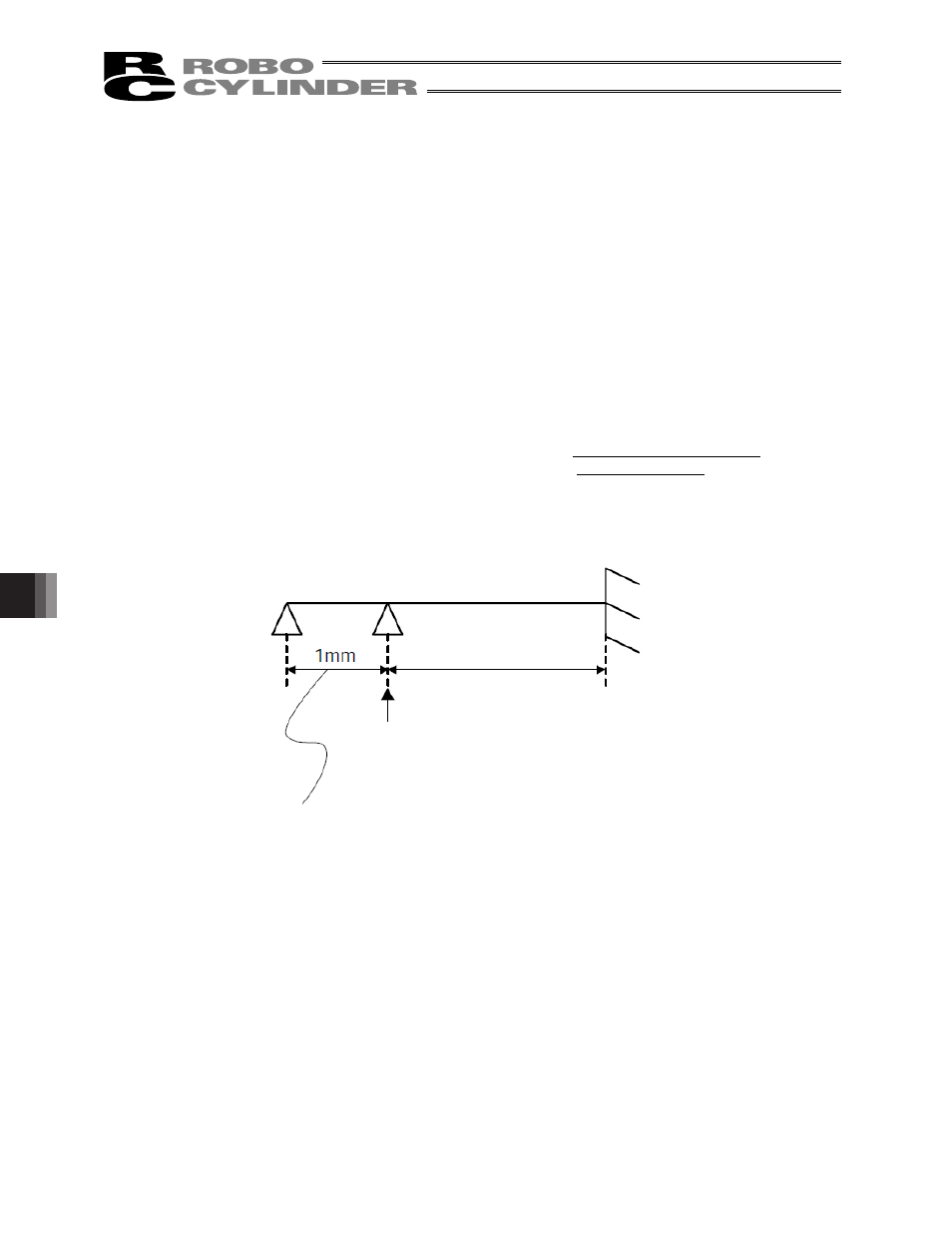

Home position

Z-phase ON

position

Mechanical end

Approx. 2 mm

The countermark on the motor aligns

with this position.

Use Parameter home return offset distance (SCON) or home preset

value (SSEL and X-SEL) to specify the settings

(The values displayed above are factory default settings).

11.9.6

Replacing the Belt of the Motor Reversing Type (RCS2-SA4R, SA5R, SA6R)

[Items Required for Replacement]

�

Replacement belt

�

Allen wrenches

�

Phillips screwdriver

�

Tension gauge (capable of tensioning to 7 kgf or greater)

�

Strong string, looped (or long tie-band)

�

Scale

�

Oil-based marker pen

�

PC or teaching pendant

[Overview of Replacement]

1) Move the slider to a position where Z-phase turns on (home position) (2 mm from the mechanical end). In this

position, loosen the motor-unit affixing bolts and replace the belt.

2) Restore the home position.

Affix the slider at a position 2 mm from the mechanical end on the home side, pass the belt, and adjust the

belt to the specified tension.

3) Perform homing using a PC or teaching pendant and check for deviation from the initial home position.

If there is a deviation when the SCON controller is being used, use home return offset distance to make the

adjustments. If the SSEL or the X-SEL controller is being used, use home preset value to make the

adjustments.

- RCS3PCR-SA8C RCS3CR-SS8C RCS3CR-SA8C RCS3P-SS8C RCS3P-SA8C RCS3-SS8C RCS3-SA8C RCS2CR-SS8C RCS2CR-SS7C RCS2CR-SA7C RCS2CR-SA6D RCS2CR-SA6C RCS2CR-SA5D RCS2CR-SA5C RCS2CR-SA4C RCS2-SS8R RCS2-SS8C RCS2-SS7R RCS2-SS7C RCS2-SA7R RCS2-SA7C RCS2-SA6R RCS2-SA6D RCS2-SA6C RCS2-SA5R RCS2-SA5D RCS2-SA5C RCS2-SA4R RCS2-SA4D RCS2-SA4C