5 tightening screws – IAI America RCS3PCR-SS8C User Manual

Page 64

5. Installation

54

5.5 Tightening Screws

�

The male screws for mounting the base should be M3 for SA4, M4 for SA5, M5 for SA6/SA7/SS7, and M8 for

SS8. (Use hexagon socket-head bolts).

�

For the bolts, we recommend high strength bolts of ISO-10.9 or higher.

�

When using a foot base to attach to a mounting table, use the special washer made for high strength bolts

that comes with the actuator if the bolt is M8 or larger. This is unnecessary for M6 or smaller bolts. Do not

use a common spring washer.

�

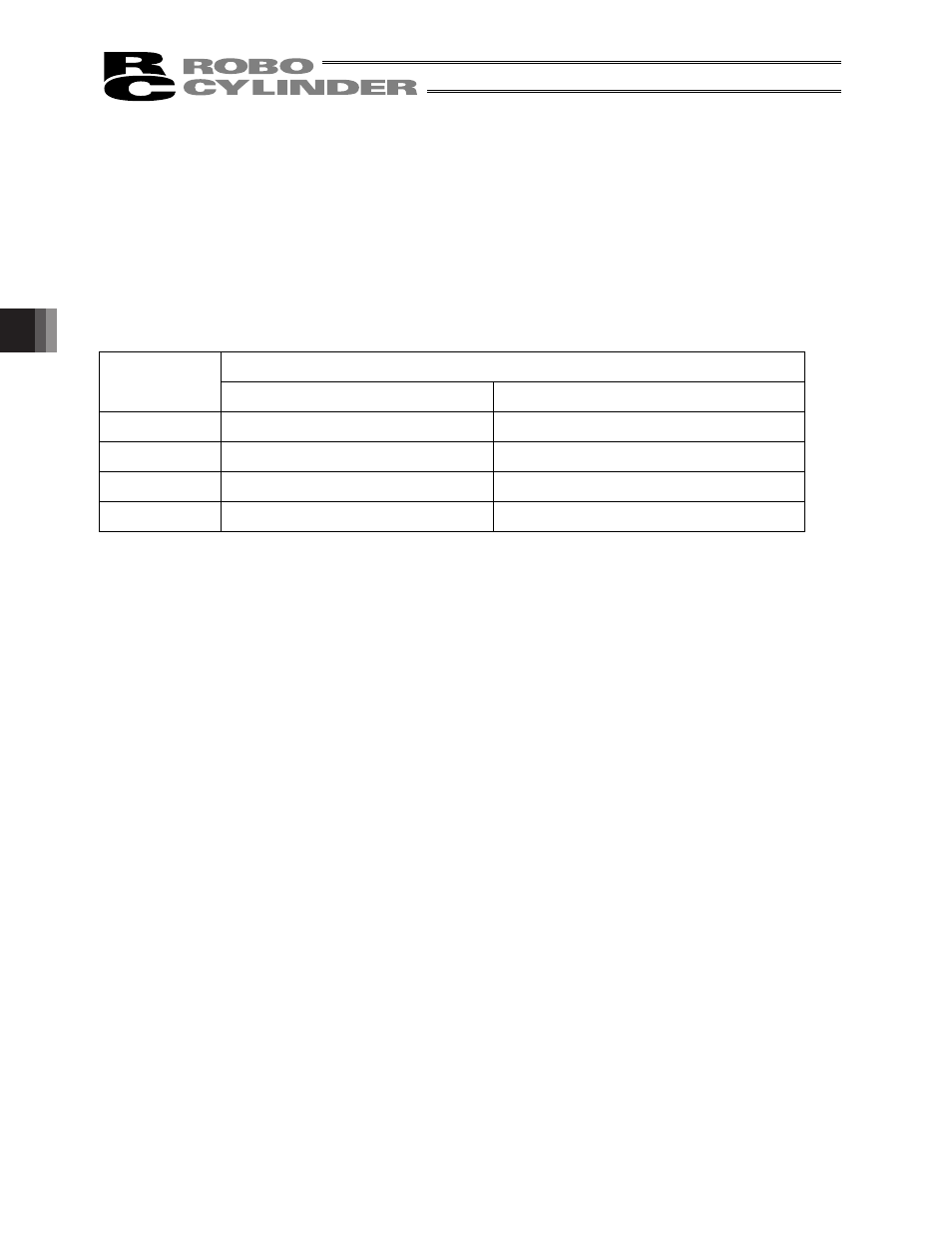

The recommended tightening torque is given below.

Tightening Torque

Screw nominal

diameter

When the bolt seating surface is steel When the bolt seating surface is aluminum

M3

1.5 N�m (0.15 kgf�m)

0.8 N�m (0.08 kgf�m)

M4

3.6 N�m (0.37 kgf�m)

1.8 N�m (0.18 kgf�m)

M5

7.3 N�m (0.74 kgf�m)

3.4 N�m (0.35 kgf�m)

M8

30.0 N�m (3.05 kgf�m)

11.5 N�m (1.17 kgf�m)

- RCS3PCR-SA8C RCS3CR-SS8C RCS3CR-SA8C RCS3P-SS8C RCS3P-SA8C RCS3-SS8C RCS3-SA8C RCS2CR-SS8C RCS2CR-SS7C RCS2CR-SA7C RCS2CR-SA6D RCS2CR-SA6C RCS2CR-SA5D RCS2CR-SA5C RCS2CR-SA4C RCS2-SS8R RCS2-SS8C RCS2-SS7R RCS2-SS7C RCS2-SA7R RCS2-SA7C RCS2-SA6R RCS2-SA6D RCS2-SA6C RCS2-SA5R RCS2-SA5D RCS2-SA5C RCS2-SA4R RCS2-SA4D RCS2-SA4C