10 replacing the motor – IAI America RCS3PCR-SS8C User Manual

Page 124

11. Maintenance and Inspection

114

Home position

Z-phase ON

position

Mechanical end

Approx. 2 mm

The countermark on the motor

aligns with this position.

Use Parameter home return offset distance (SCON) or home

preset value (SSEL and X-SEL) to specify the settings

(The values displayed above are factory default settings).

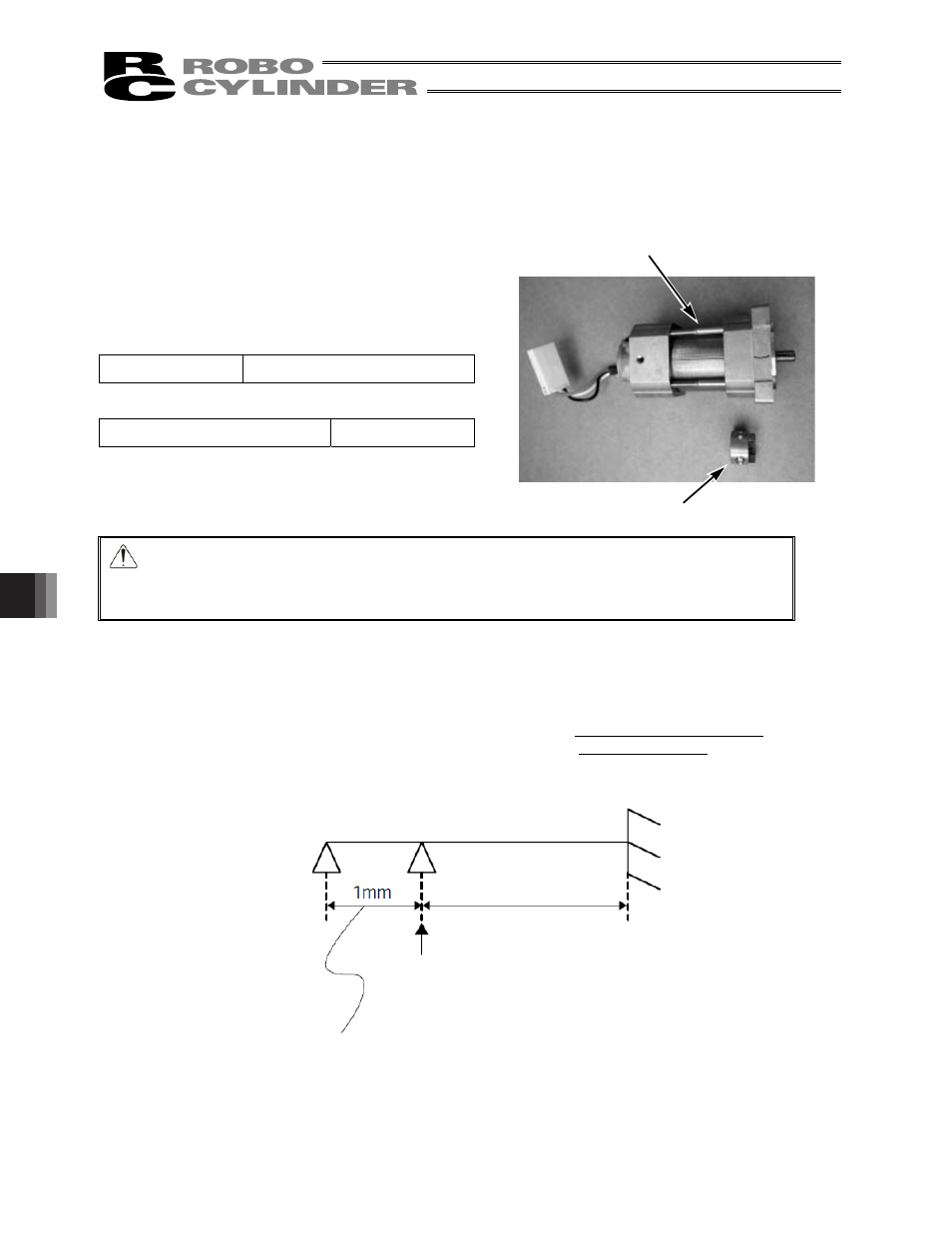

Example: Replacement motor (IAI encoder)

Coupling (with screws)

11.10 Replacing the Motor

11.10.1

Replacing the Motor of the Motor Straight Type (Coupling Type) (Made by IAI)

: RCS2-SA4C, SA5C, SA6C

[Items Required for Replacement]

�

Replacement motor

�

Coupling (with screws)

�

Allen wrenches

�

Phillips screwdriver

�

Scale

�

Oil-based marker pen

�

Grease

Other than cleanroom specification

Idemitsu Kosan

Daphne Eponex Grease No.2

Cleanroom specification

Kuroda Precision Industries

C Grease

• PC or teaching pendant

Caution: When replacing the motor, handle the replacement motor with due care. The

actuator has been shipped with the encode adjusted to an optimal position, so do

not crush the encoder unit. It may displace the encoder, thus impairing proper

actuator operation.

[Overview of Replacement]

1) Move the slider to a position where Z-phase turns on (home position) (2 mm from the mechanical end).

Replace the motor in this position.

2) Perform homing using a PC or teaching pendant and check for deviation from the initial home position.

If there is a deviation when the SCON controller is being used, use home return offset distance to make the

adjustments. If the SSEL or the X-SEL controller is being used, use home preset value to make the

adjustments.

- RCS3PCR-SA8C RCS3CR-SS8C RCS3CR-SA8C RCS3P-SS8C RCS3P-SA8C RCS3-SS8C RCS3-SA8C RCS2CR-SS8C RCS2CR-SS7C RCS2CR-SA7C RCS2CR-SA6D RCS2CR-SA6C RCS2CR-SA5D RCS2CR-SA5C RCS2CR-SA4C RCS2-SS8R RCS2-SS8C RCS2-SS7R RCS2-SS7C RCS2-SA7R RCS2-SA7C RCS2-SA6R RCS2-SA6D RCS2-SA6C RCS2-SA5R RCS2-SA5D RCS2-SA5C RCS2-SA4R RCS2-SA4D RCS2-SA4C