IAI America RCS3PCR-SS8C User Manual

Page 46

2. Specification

37

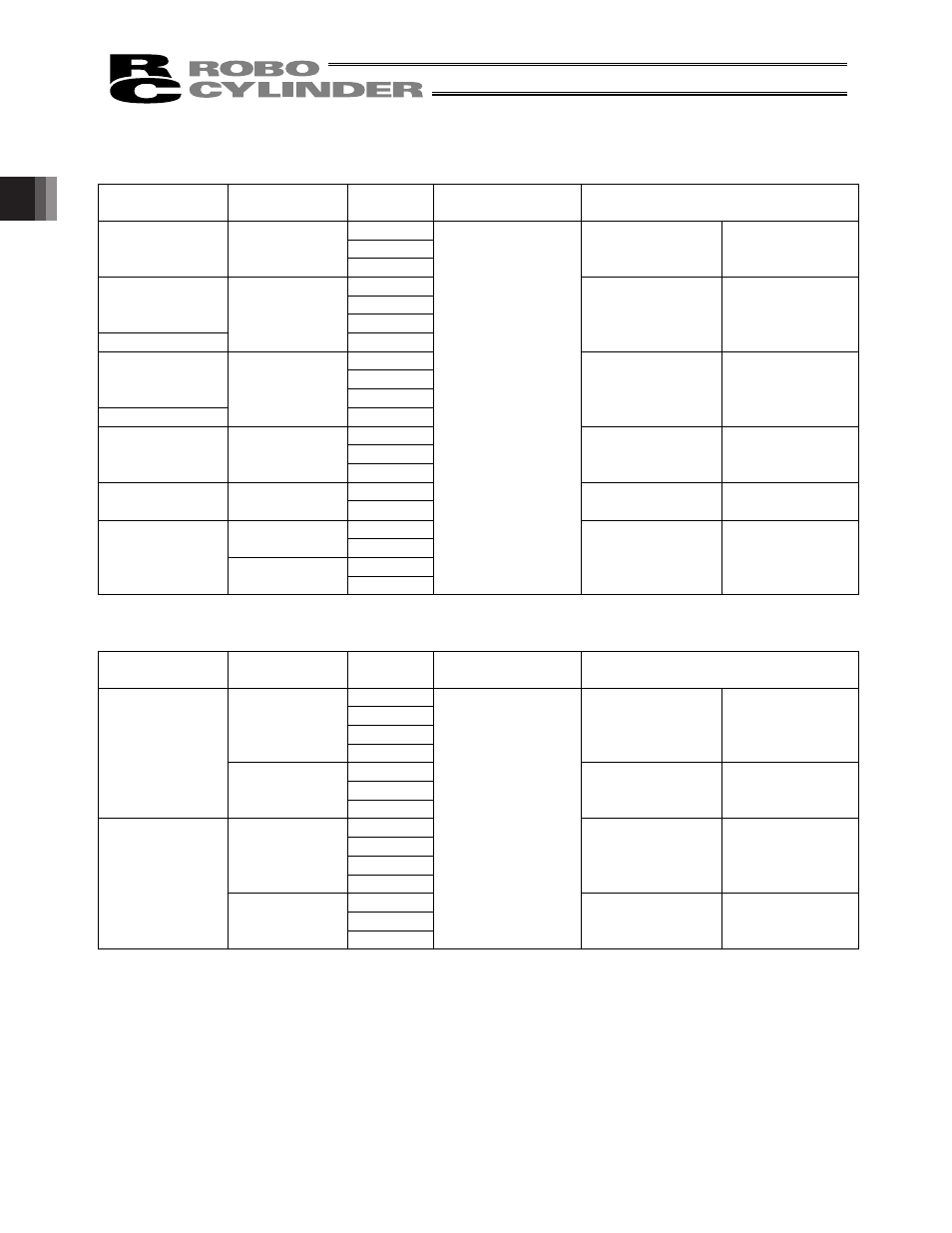

(4) Driving method

[RCS2 Cleanroom specification RCS2CR]

Type

Motor capacity

[W]

Lead

Encoder pulses

*1

Driving method

2.5

5

SA4

20

10

Ball screw

�

8 mm

Rolled, C10

3

6

SA5

12

RCS2-SA5C

20

20

Ball screw

�

10 mm

Rolled, C10

3

6

SA6

12

RCS2-SA5C

30

20

Ball screw

�

10 mm

Rolled, C10

4

8

SA7

60

16

Ball screw

�

12 mm

Rolled, C10

6

SS7

60

12

Ball screw

�

10 mm

Rolled, C10

10

100

20

10

SS8

150

20

16384

Ball screw

�

16 mm

Rolled, C10

*1. Number of pulses input to the controller.

[RCS3 (P) Cleanroom specification RCS3 (P) CR]

Type

Motor capacity

[W]

Lead

Encoder pulses

*1

Driving method

5

10

20

100

30

Ball screw

�

16 mm

Rolled, C10

[Rolled, C5 or

equivalent]

10

20

SA8

150

30

Ball screw

�

16 mm

Rolled, C10

[Rolled, C5 or

equivalent]

5

10

20

100

30

Ball screw

�

16 mm

Rolled, C10

[Rolled, C5 or

equivalent]

10

20

SS8

150

30

16384

Ball screw

�

16 mm

Rolled, C10

[Rolled, C5 or

equivalent]

*1. Number of pulses input to the controller.

- RCS3PCR-SA8C RCS3CR-SS8C RCS3CR-SA8C RCS3P-SS8C RCS3P-SA8C RCS3-SS8C RCS3-SA8C RCS2CR-SS8C RCS2CR-SS7C RCS2CR-SA7C RCS2CR-SA6D RCS2CR-SA6C RCS2CR-SA5D RCS2CR-SA5C RCS2CR-SA4C RCS2-SS8R RCS2-SS8C RCS2-SS7R RCS2-SS7C RCS2-SA7R RCS2-SA7C RCS2-SA6R RCS2-SA6D RCS2-SA6C RCS2-SA5R RCS2-SA5D RCS2-SA5C RCS2-SA4R RCS2-SA4D RCS2-SA4C