IAI America RCS3PCR-SS8C User Manual

Page 118

0

11. Maintenance and Inspection

108

11.9.7

Replacing the Belt of the Motor Reversing Type (RCS2-SA7R)

[Items Required for Replacement]

�

Replacement belt � Allen wrenches � Tension gauge (capable of tensioning to 8 kgf or greater)

�

Strong string, looped (or long tie-band) � PC or teaching pendant

[Overview of Replacement]

1) Loosen the tension adjustment bolts and replace the belt.

2) Restore the home position.

Press the slider against the mechanical end on the home side, and move the motor shaft away from the

countermark by the specified distance. With the slider and motor shaft affixed in these positions, adjust the

belt to the specified tension.

3) Perform homing using a PC or teaching pendant and check for deviation from the initial home position.

If there is a deviation when the SCON controller is being used, use home return offset distance to make the

adjustments. If the SSEL or the X-SEL controller is being used, use home preset value to make the

adjustments.

[Procedure]

1) Move the slider from the home position toward the mechanical end and check the rotating direction of the

motor. (This check is necessary, because the rotating direction of the motor is different on actuators whose

home is set on the opposite side.)

�

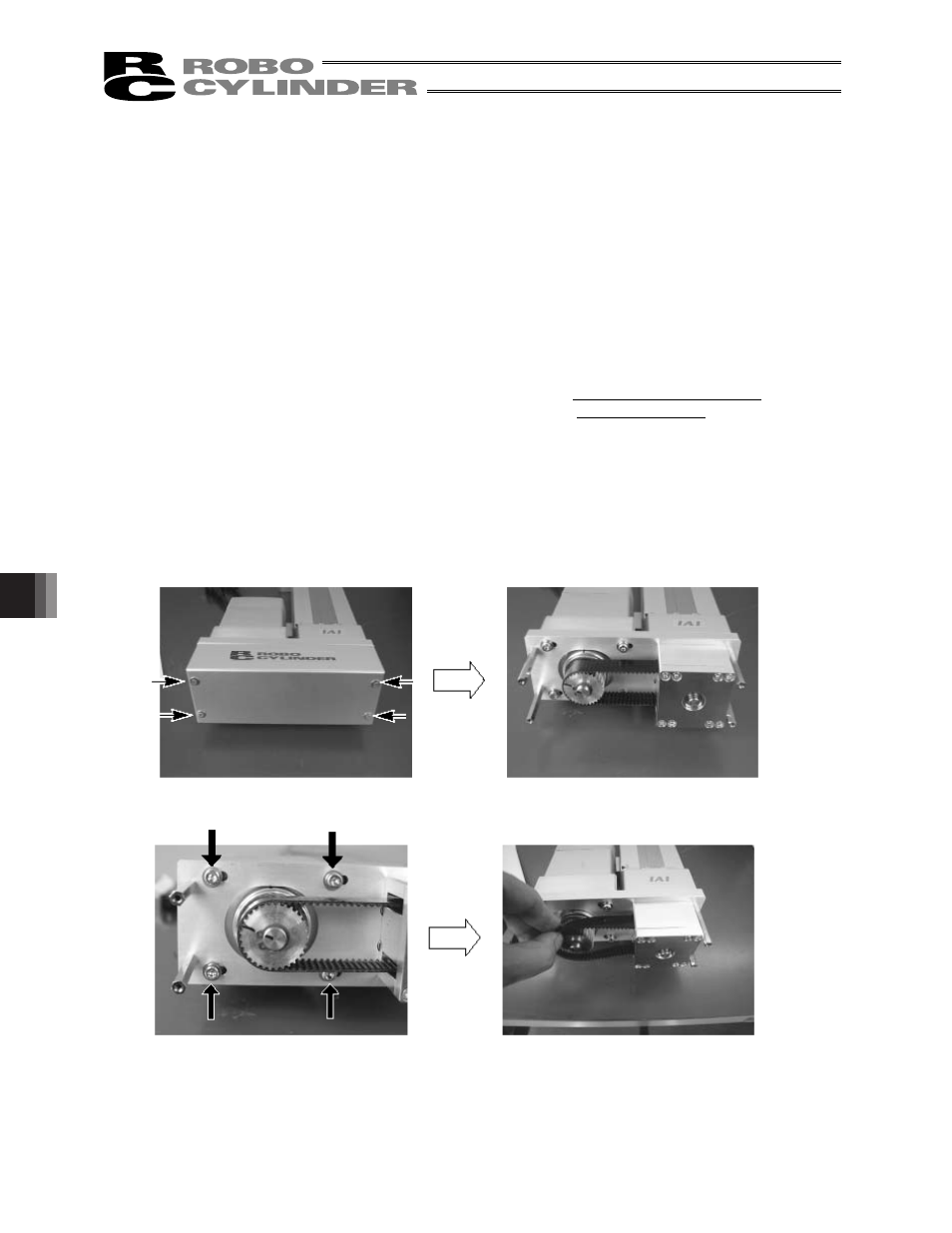

Remove the pulley cover.

(Remove the three thin-head mounting screws using an Allen wrench.)

2) Loosen the four tension adjustment bolts and move the motor bracket to slack the belt.

- RCS3PCR-SA8C RCS3CR-SS8C RCS3CR-SA8C RCS3P-SS8C RCS3P-SA8C RCS3-SS8C RCS3-SA8C RCS2CR-SS8C RCS2CR-SS7C RCS2CR-SA7C RCS2CR-SA6D RCS2CR-SA6C RCS2CR-SA5D RCS2CR-SA5C RCS2CR-SA4C RCS2-SS8R RCS2-SS8C RCS2-SS7R RCS2-SS7C RCS2-SA7R RCS2-SA7C RCS2-SA6R RCS2-SA6D RCS2-SA6C RCS2-SA5R RCS2-SA5D RCS2-SA5C RCS2-SA4R RCS2-SA4D RCS2-SA4C