4 installation surface – IAI America RCS3PCR-SS8C User Manual

Page 61

5. Installation

51

�

5.4 Installation Surface

�

The mounting table should have sufficient rigidity to avoid generating vibration.

�

The surface where the actuator will be mounted should be machined or be equally level and the flatness

tolerance between the actuator and the table should be within � 0.05 mm.

�

Provide enough space around the actuator to permit maintenance work to be done.

5.4.1

Using Side Faces of the Base as Reference Planes

[RCS2 (CR)]

�

The side and bottom faces of the actuator base provide the reference planes for slider travel.

�

When precision is required, use these surfaces as the reference planes for mounting.

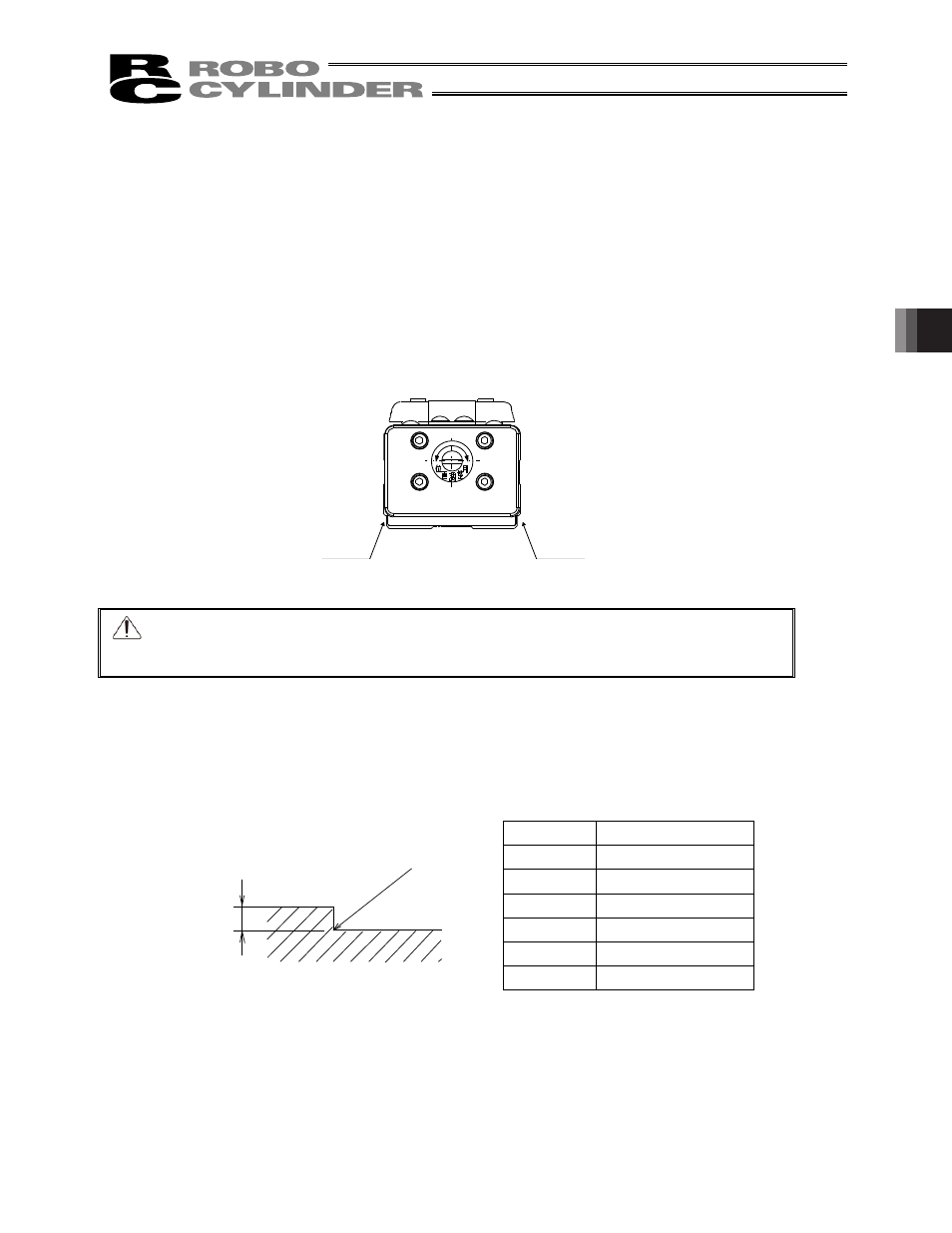

Caution: As shown above, the side faces of the base provide the reference planes for

slider travel. When precision is required, use these surfaces as the reference

planes for mounting.

When using the base as the reference planes for mounting the actuator to the machine frame, follow the

machining dimensions shown below.

Type

Dimension A [mm]

SA4

2 to 3

SA5

2 to 4.5

SA6

2 to 4.5

SA7

2 to 5.5

SS7

2 to 4

SS8

2 to 4.5

(side face of the base)

R0.3 or less

Reference plane

(side face of the base)

Reference plane

For position

adjustment

- RCS3PCR-SA8C RCS3CR-SS8C RCS3CR-SA8C RCS3P-SS8C RCS3P-SA8C RCS3-SS8C RCS3-SA8C RCS2CR-SS8C RCS2CR-SS7C RCS2CR-SA7C RCS2CR-SA6D RCS2CR-SA6C RCS2CR-SA5D RCS2CR-SA5C RCS2CR-SA4C RCS2-SS8R RCS2-SS8C RCS2-SS7R RCS2-SS7C RCS2-SA7R RCS2-SA7C RCS2-SA6R RCS2-SA6D RCS2-SA6C RCS2-SA5R RCS2-SA5D RCS2-SA5C RCS2-SA4R RCS2-SA4D RCS2-SA4C