IAI America RCS3PCR-SS8C User Manual

Page 186

11. Maintenance and Inspection

166

11.10.7

Replacing the Motor of the Motor Reversing Type: RCS3 (P)- SA8R, SS8R

[Items Required for Replacement]

�

Replacement motor unit

�

Allen wrenches

�

Phillips screwdriver

�

Sound-wave tension gauge or tension gauge (capable of withstanding at least 15 kg of tension)

�

Long tie-band (thin string)

�

Measuring tape

�

Oil-based marker pen

�

PC or teaching pendant

[Overview of Replacement]

1) Loosen the bolts securing the motor unit and replace the motor.

2) Restore the home position.

Fix the slider at a position 2 mm from the mechanical end on home side, pass the belt, and adjust the belt to

the specified tension.

3) Perform homing using a PC or teaching pendant and check for deviation from the initial home position. If

there is a deviation when the SCON controller is being used, use home return offset distance to make the

adjustments. If the SSEL or the X-SEL controller is being used, use home preset value to make the

adjustments.

[Procedure]

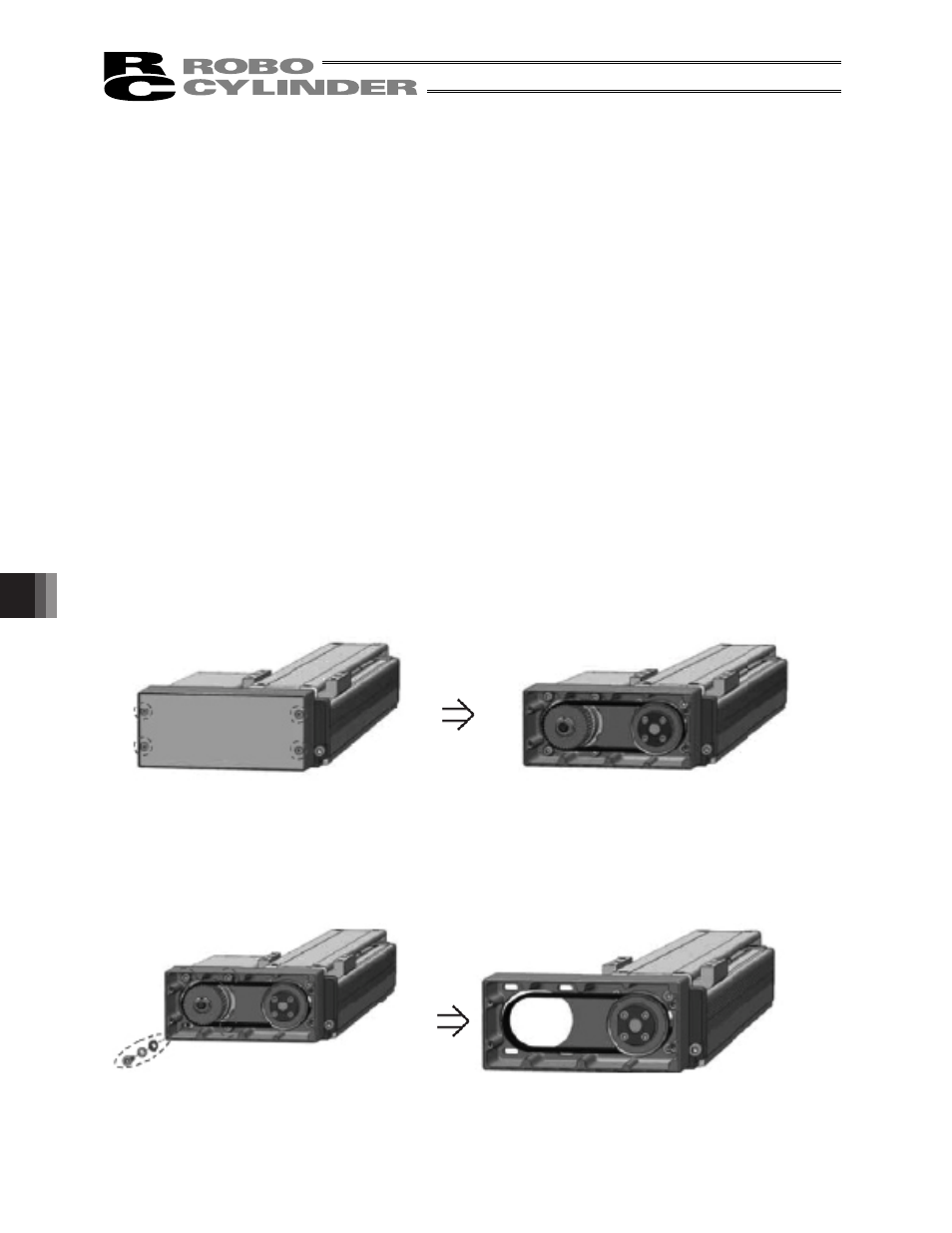

1) Remove the pulley cover.

Applicable wrench : 2 mm across flats

Applicable bolt

: Hexagonal socket head bolt _M3 x 5 (SUS), 4 pcs

2) Remove the motor unit.

Applicable wrench : 3 mm across flats

Applicable bolt

: Hexagonal socket head bolt _M4 x 16, 4 pcs

Washer : M4 flat washer, M4 spring washer #2

- RCS3PCR-SA8C RCS3CR-SS8C RCS3CR-SA8C RCS3P-SS8C RCS3P-SA8C RCS3-SS8C RCS3-SA8C RCS2CR-SS8C RCS2CR-SS7C RCS2CR-SA7C RCS2CR-SA6D RCS2CR-SA6C RCS2CR-SA5D RCS2CR-SA5C RCS2CR-SA4C RCS2-SS8R RCS2-SS8C RCS2-SS7R RCS2-SS7C RCS2-SA7R RCS2-SA7C RCS2-SA6R RCS2-SA6D RCS2-SA6C RCS2-SA5R RCS2-SA5D RCS2-SA5C RCS2-SA4R RCS2-SA4D RCS2-SA4C