IAI America RCS3PCR-SS8C User Manual

Page 122

11. Maintenance and Inspection

112

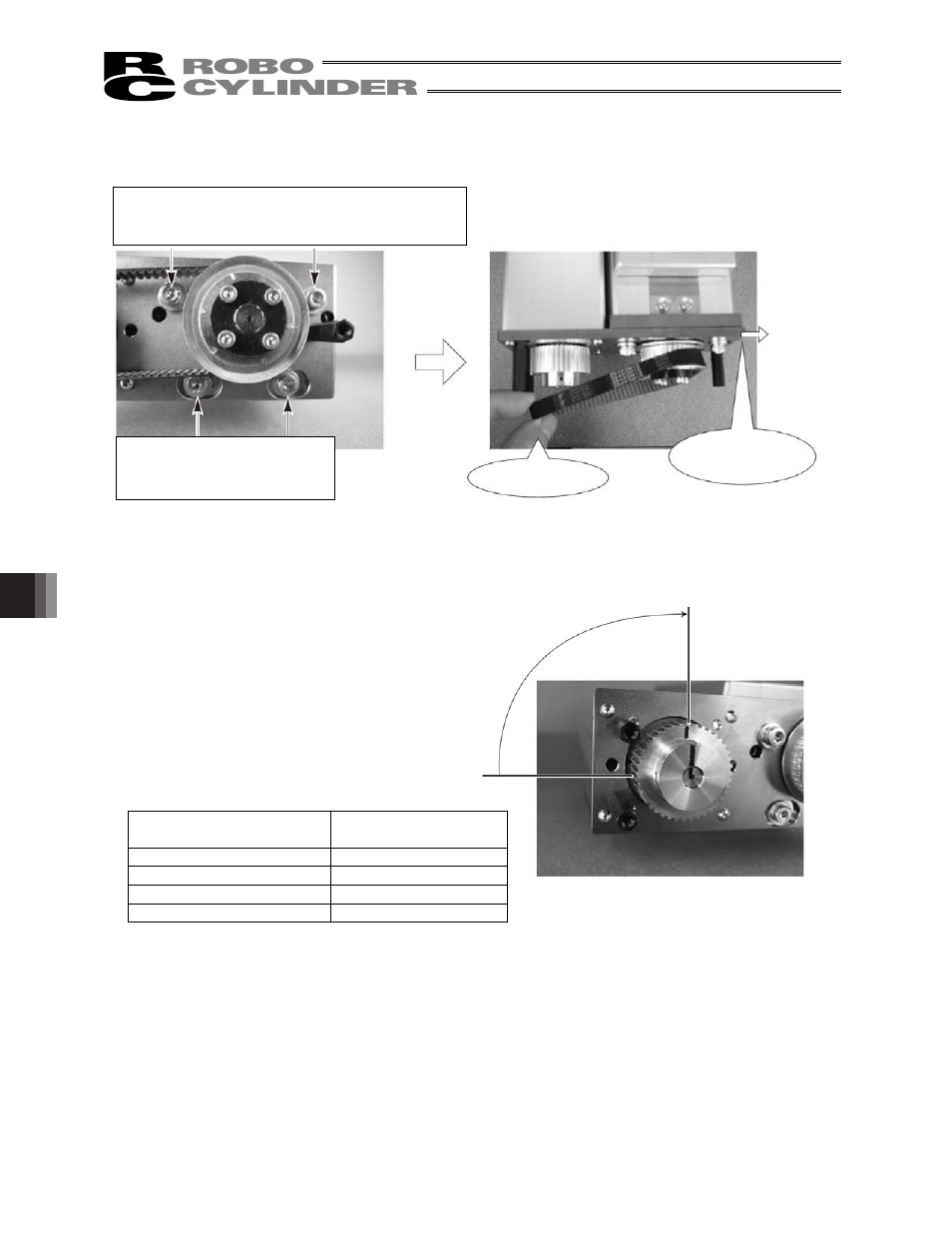

Tension adjustment bolts

(Use an Allen wrench of 3 mm

across flats.)

Tension adjustment bolts

(Use an Allen wrench of 3 mm across flats for

SS7R and of 4 mm across flats for SS8R.)

Remove by

hand.

Move the motor

bracket.

Initial countermark position

Example for SS7R-12/SS8R-10 types:

Turn 90 degrees in the direction of

returning to the mechanical end

(standard home specification).

2) Loosen the tension adjustment bolts and move the motor bracket to slack and remove the belt.

3) Make the adjustment to restore the home position.

�

Press the slider against the mechanical end on the home side and affix the slider in this position.

�

Turn the motor shaft away from the countermark by the specified distance in the direction of returning to

the mechanical end (the direction checked earlier).

Type

Return angle from

countermark position

SS7R-12 (high speed)

90 degrees

SS7R-6 (medium speed)

180 degrees

SS8R-20 (high speed)

45 degrees

SS8R-10 (medium speed)

90 degrees

�

Pass the new belt by making sure the pulleys on both sides do not move.

- RCS3PCR-SA8C RCS3CR-SS8C RCS3CR-SA8C RCS3P-SS8C RCS3P-SA8C RCS3-SS8C RCS3-SA8C RCS2CR-SS8C RCS2CR-SS7C RCS2CR-SA7C RCS2CR-SA6D RCS2CR-SA6C RCS2CR-SA5D RCS2CR-SA5C RCS2CR-SA4C RCS2-SS8R RCS2-SS8C RCS2-SS7R RCS2-SS7C RCS2-SA7R RCS2-SA7C RCS2-SA6R RCS2-SA6D RCS2-SA6C RCS2-SA5R RCS2-SA5D RCS2-SA5C RCS2-SA4R RCS2-SA4D RCS2-SA4C