Mechanism description 2.1 general mechanism, 2 hopper mechanism – Oki B4100 User Manual

Page 602

40055101TH Rev.4

602 /

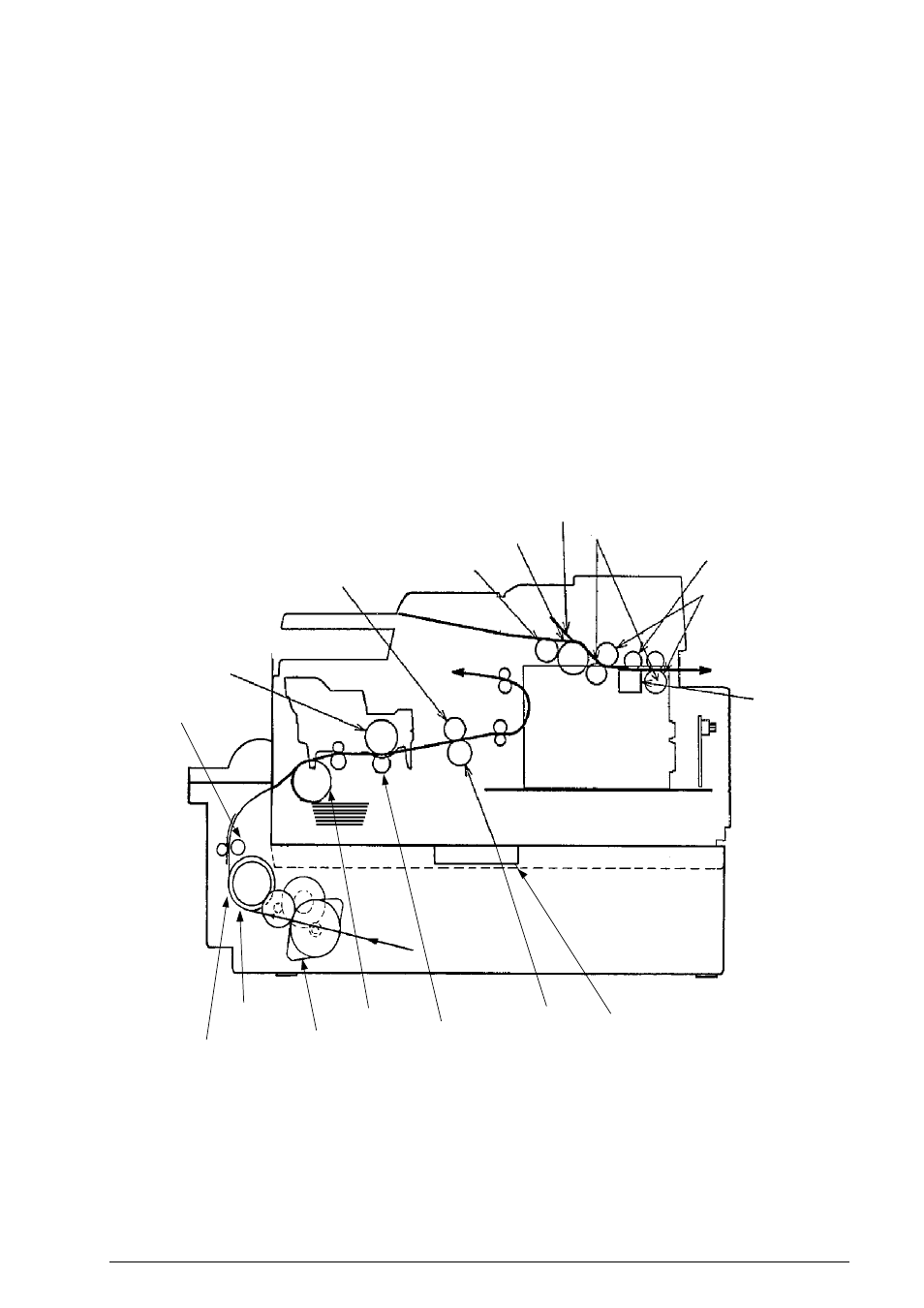

Heater roller

Sub roller

ADF roller

Separation rubber

Pinch rollers

Scan roller

Feed rollers

Image sensor

EP drum

Feed roller

One-way clutch roller

Hopping roller

Pulse motor

Hopping roller

Transfer roller

Back-up roller

Handling hall

2.

MECHANISM DESCRIPTION

2.1

General Mechanism

The Second Paper Feeder feeds the paper into the facsimile by receiving the signal from the facsimile, which

drives the pulse motor inside the Second Paper Feeder, and this motion is transmitted to rotate the one-way

clutch of the hopping frame assembly. The paper is delivered from the hopper into the facsimile through the

turning of the hopping roller and feed roller.

Once delivered into the facsimile, the paper is then controlled and fed through by pulse motor (registration)

of the facsimile.

2.2

Hopper Mechanism

The hopper automatically feeds the facsimile with the paper being set, single sheet at a time. When the paper

is loaded in the paper cassette, it is then transported by the pulse motor, carrying forward only a single sheet

caught by the separation rubber at a time.