INFICON Cygnus 2 Thin Film Deposition Controller User Manual

Page 260

14 - 12

IP

N 07

4-

54

5-

P1

E

Cygnus 2 Operating Manual

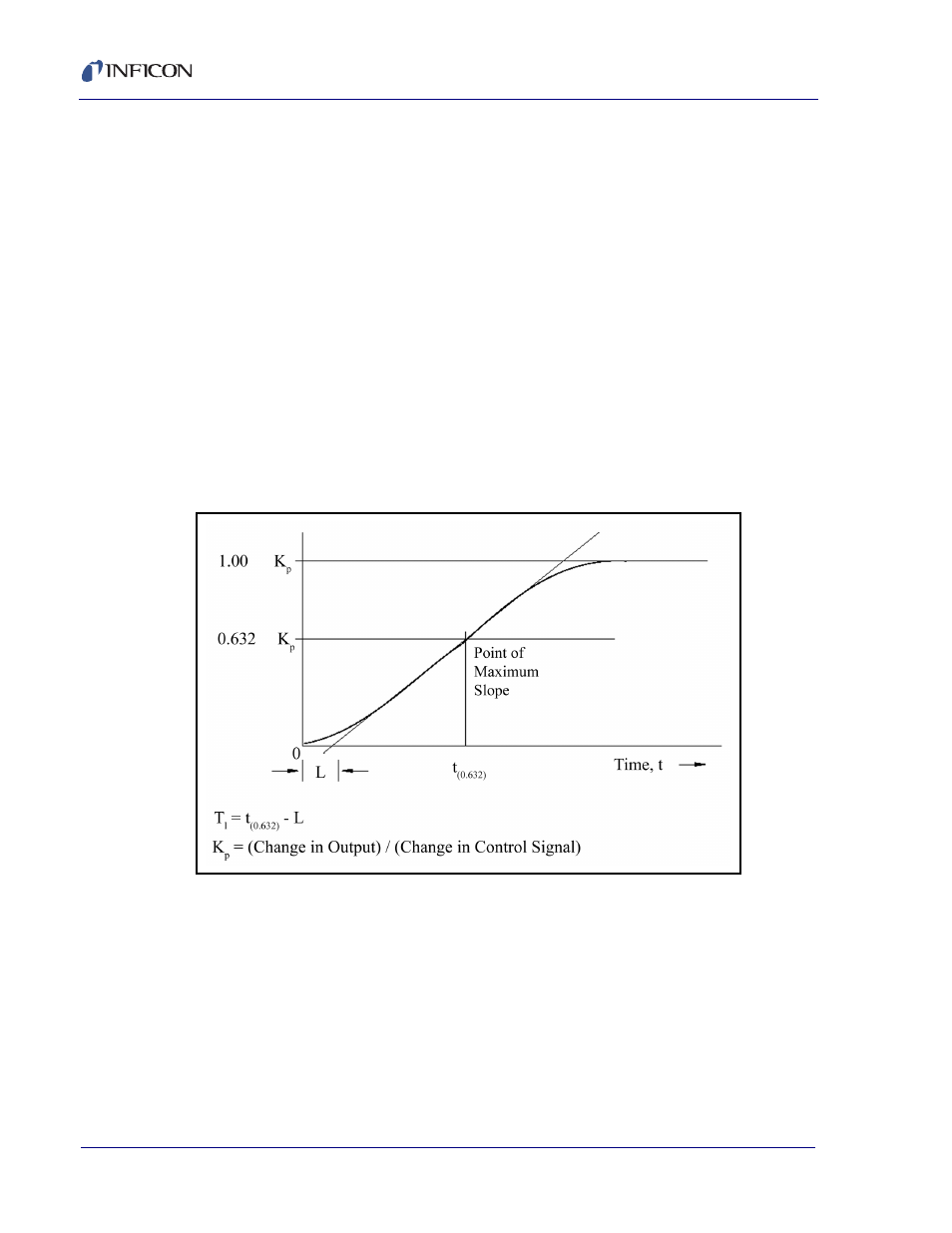

In general, it is not possible to characterize all processes exactly; some

approximation must be applied. The most common is to assume that the dynamic

characteristics of the process can be represented by a first-order lag plus a dead

time. The Laplace transform for this model (conversion to the s domain) is

approximated as:

[8]

Three parameters are determined from the process reaction curve. They are the

steady state gain, K

p

, the dead time, L, and the time constant, T

1

. Several methods

have been proposed to extract the required parameters from the system response

as graphed in

. These are: a one point fit at 63.2% of the transition (one

time constant); a two point exponential fit; and a weighted least-square-exponential

fit. From the above information a process is sufficiently characterized so that a

controller algorithm may be customized.

Figure 14-7 Response of process to an open loop step change

(At t=0 control signal is increased)

A controller model used extensively is the PID type, shown in Laplace form in

[9]

Where

M(s) = manipulated variable or power

K

c

= controller gain (the proportional term)

Output

Input

------------------

K

p

L

– s

exp

T

1

s 1

+

-------------------------------

=

M s

K

c

1

1

T

i

s

------- T

d

s

+

+

Es

=