INFICON Cygnus 2 Thin Film Deposition Controller User Manual

Page 233

13 - 17

IP

N 07

4-

54

5-

P1

E

Cygnus 2 Operating Manual

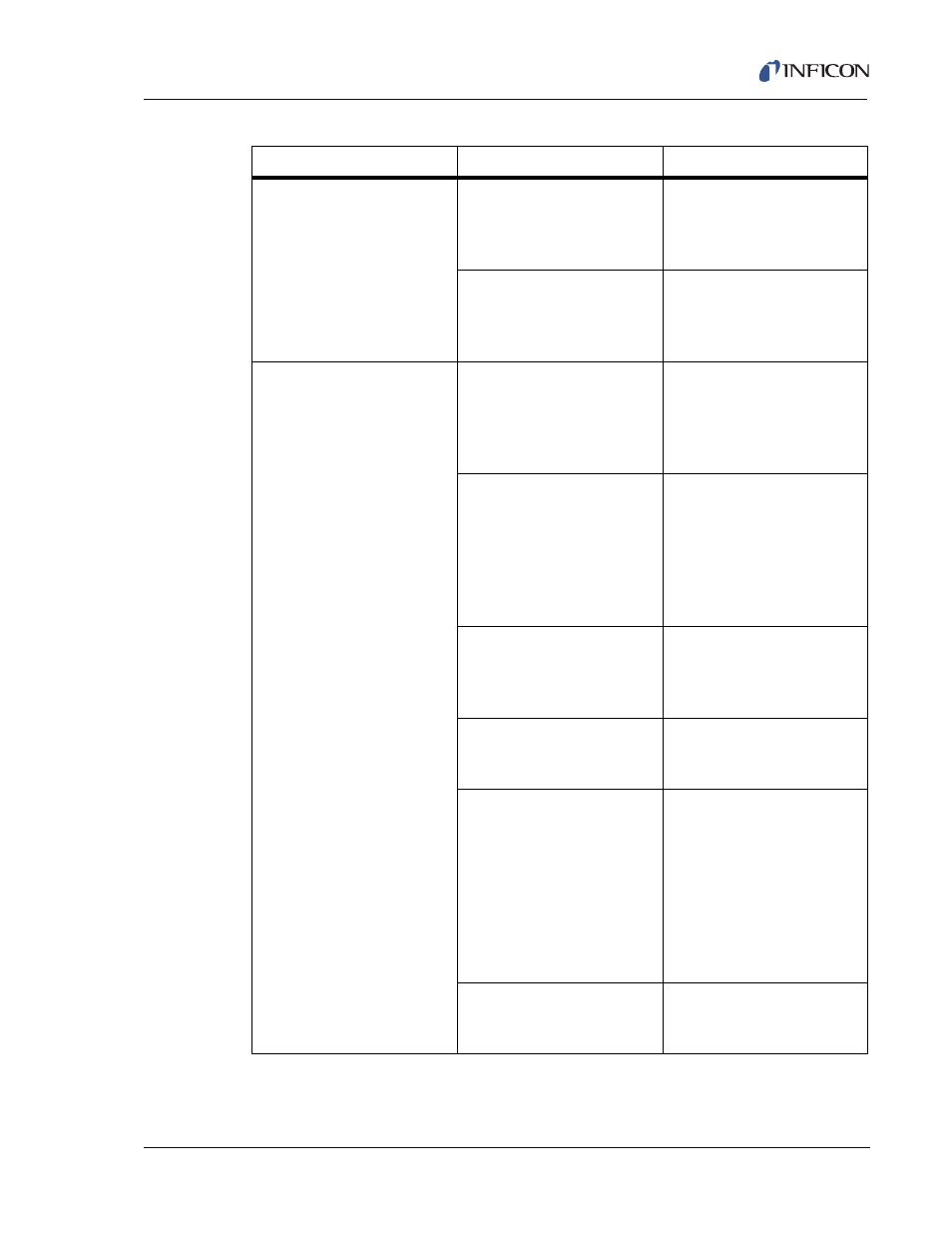

4. Crystal oscillates in

vacuum but stops oscillation

after open to air

a. Crystal was near the end

of its life; opening to air

causes film oxidation which

increases film stress

a. Replace crystal

b. Excessive moisture

accumulates on the crystal

b. Turn off cooling water to

sensor prior to venting, flow

warm water through sensor

while chamber is open

5. Thermal instability: large

changes in thickness reading

during source warm-up

(usually causes thickness

reading to decrease) and

after the termination of

deposition (usually causes

thickness reading to

increase)

a. Inadequate cooling

water/cooling water

temperature too high

a. Check cooling water flow

rate, be certain that cooling

water temperature is less

than 30 °C; refer to

appropriate sensor manual

b. Excessive heat input to the

crystal

b. If heat is due to radiation

from the evaporation source,

move sensor further away

from source and use

sputtering crystals for better

thermal stability; install

radiation shield

c. Crystal not seated properly

in holder

c. Clean or polish the crystal

seating surface on the crystal

holder; refer to appropriate

sensor manual

d. Crystal heating caused by

high energy electron flux

(often found in RF sputtering)

d. Use a sputtering sensor

head

e. Poor thermal transfer from

water tube to body (XtalSix

sensor)

e. Use a new water tube

whenever the clamping

assembly has been removed

from the body; if a new water

tube is not available, use a

single layer of aluminum foil

between the cooling tube and

sensor body, if your process

allows

f. Poor thermal transfer

(Bakeable)

f. Use Al or Au foil washer

between crystal holder and

sensor body

Table 13-7 Troubleshooting transducers/sensors (continued)

SYMPTOM

CAUSE

REMEDY