6 assembling the mounting brackets (sl-vf/vh/vl), Assembling the mounting brackets (sl-vf/vh/vl) -15, J (op-83180) -15 – KEYENCE SL-V Series User Manual

Page 91: Assembling the mounting brackets (sl-vf/vh/vl), Danger

3-15

In

3

SL-V-M-NO3-E

3-6

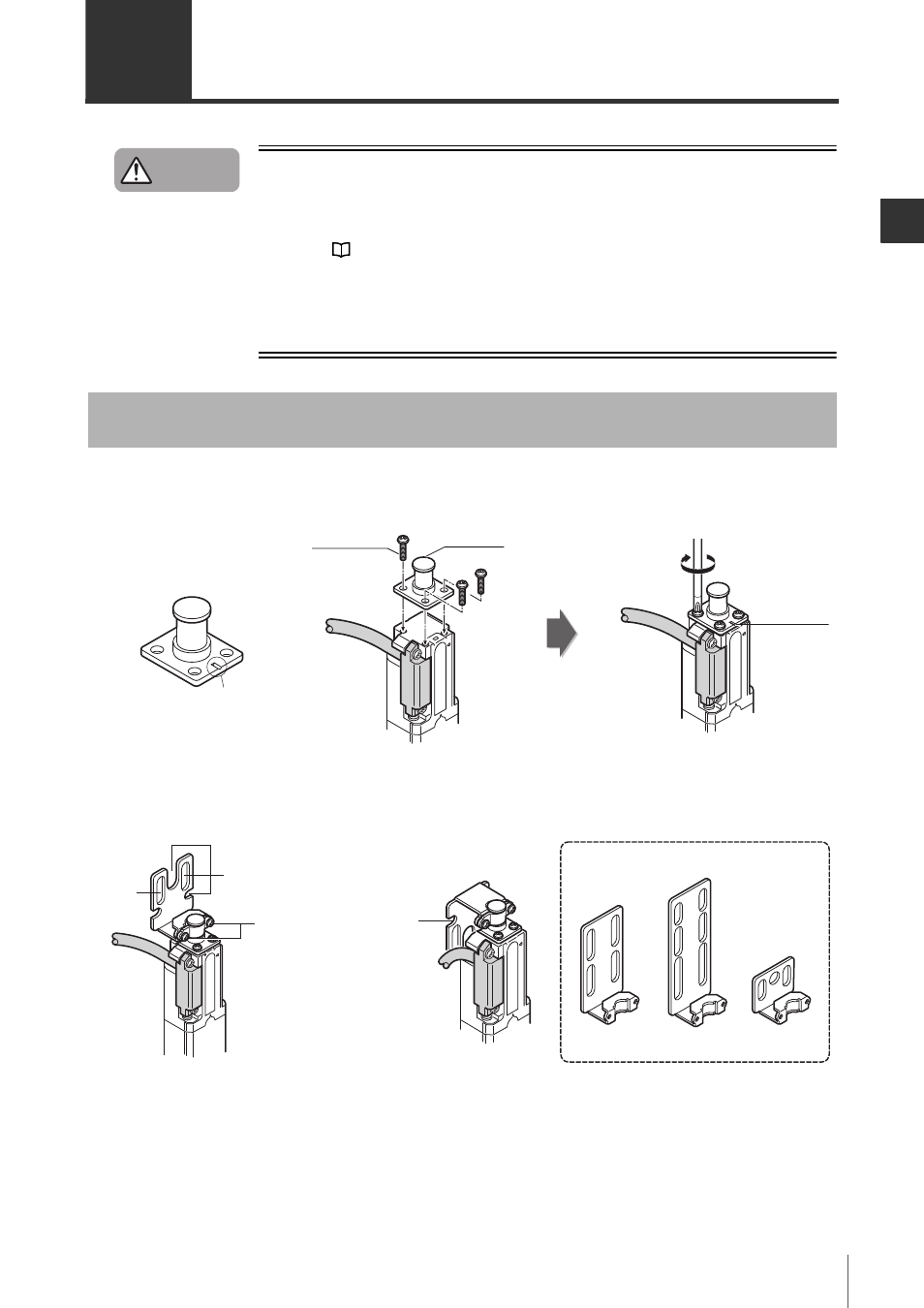

Assembling the Mounting Brackets (SL-VF/VH/VL)

The installation holes for screws on mounting brackets for the SL-V are slot-shaped so that

they are larger than the actual screw size with which they are intended to be used. This

additional space can be used to adjust the position in which the device is installed. For this

reason, the proper installation of the device should be verified according to the procedure

outlined in

"Regular (periodical) inspection" (page A-10) in the event that maintenance

requires the removal of the device from its target equipment or the adjustment of its

installation position after its initial installation onto that target equipment. Failure to follow this

installation instruction results in a significant harm to the machine operators, including serious

injury or death.

1

Install the base bracket as shown in the following image and secure it with the three included screws. Be sure

to install the bracket so that the engraved mark on the base bracket faces in the same direction as the surface

of the SL-V.

2

A mounting bracket must be installed to the base bracket. There are four types of mounting brackets depend-

ing on the mounting conditions.

*1 M3 screws are provided to the standard mounting bracket A, B and C as well as the hexagon socket bolts. When

fixing this part with the M3 screw, the recommended tightening torque is 0.7 N·m. However, when combining the

protection bar, the hexagon socket bolt must be used.

Danger

Standard mounting bracket A (OP-42347), B (OP-42348), C (OP-42349),

J (OP-83180)

Engraved mark

Base bracket

M3 (length: 7 mm)

Engraved mark

Only standard mounting bracket

A can be used facing down.

Screw

mounting

holes

* Other types of compatible bracket

(They can be mounted in the same way.)

(Standard mounting

bracket B)

(Standard mounting

bracket C)

(Standard mounting

bracket J)

Screw mounting holes

Standard

mounting

bracket A

The SL-V can pivot by

loosening the two hexagon

socket bolts (width across

flat: 2.5 mm, length 8 mm).

Therefore, this can be used

to align the beam axis.

(Hexagon socket bolt with

a recommended tightening

torque of 1 N·m)