Autogeneration of a step program – Arc Machines 307 User Manual

Page 96

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Document No. 740096 Chapter 8. Page 8.

Rev. AA

Autogeneration of a STEP Program

STEP (or SYNCHRO) rotation mode is used for fusion welds on thin-

walled pipe up to about 0.154” wall, or tubing where extra penetration

or margin of error is required. Wall thicknesses of 0.080” or greater may re-

quire STEP mode, and thinner materials such as 0.065” wall pharmaceutical

type fittings, short sanitary ferrules or valves, may benefit. STEP may also be

useful for welding materials of dissimilar heats or with slight differences in wall

thicknesses. STEP welds take more time than welds done with continuous ro-

tation, but provide a wider bead and greater repeatability for field conditions.

In STEP mode the weld head rotor movement is synchronized with the current

pulses so that the Primary RPM takes place during the Primary Current

Pulse, and the Background RPM at the Background Current Pulse. The

stopping or slowing of the rotor during the high current pulse allows for greater

penetration without a change in amperage, and provides cooling for the weld

puddle during the background pulse.

Example Step Program

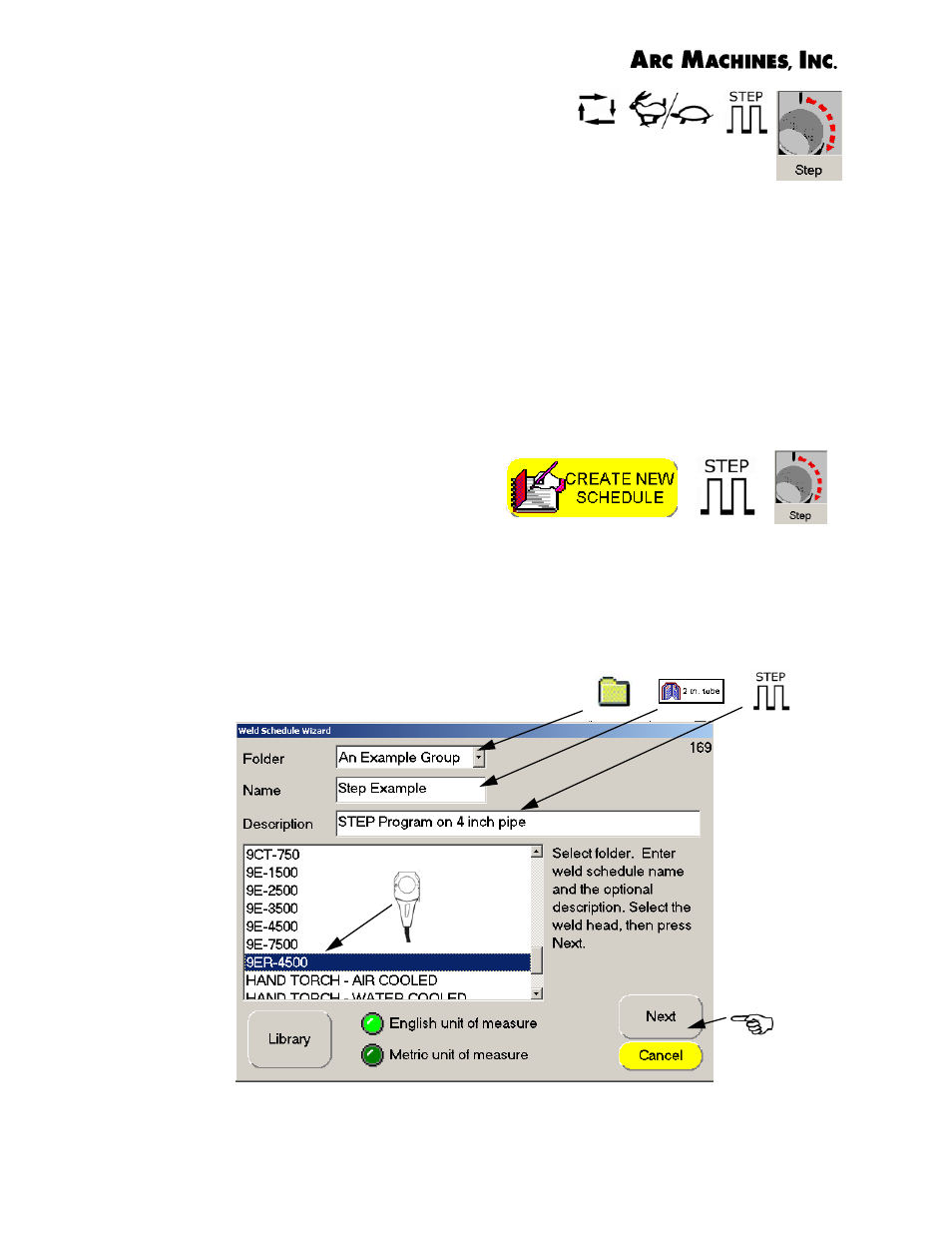

Press Create New Schedule on the 307 Opening Screen and begin by select-

ing the folder for the program from the pull-down menu. Then enter the pro-

gram name from the keyboard and the optional description. Select the weld

head by highlighting from the list of weld heads. In the following example, the

weld will be on 4 inch pipe (4.5 inches or 114.29 mm O.D.) which has a wall

thickness of 0.120 inches or 3.04 mm. Press Next when finished.