Taper angle and tip shape, Tungsten life – Arc Machines 307 User Manual

Page 151

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Document No. 740096 Chapter 15. Page 4.

Rev. A

TAPER ANGLE

AND TIP SHAPE

TUNGSTEN TIP

DIAMETERS

TUNGSTEN LIFE

Taper Angle and Tip Shape

Taper angle affects the current/voltage characteristics of

the arc and must be specified and controlled.

Arc Machines, Inc. recommends an 18

o

included angle for

the electrode tip for all tungsten diameters used in the

orbital tube and pipe weld heads. The tip shape has a con-

trolling effect on the shape of the arc and on the amount

and depth of weld penetration. A flat tip extends electrode

life and increases weld repeatability.

Tip Diameters

The Tip Diameters are specified for orbital fusion tube

welding. Tip diameters are typically based on wall thickness

with a finer tip used for thinner-walled materials. Tungstens

of a particular diameter may be ground to the users’ tip

diameter specifications.

Tungsten Life

Tungsten Life will vary with the application, quality of the

gas, and cleanliness of the metal. A great many more welds

per tungsten are possible on 1/4 inch tube than on larger

pipe. However, factors such as moisture or oxygen in the

shielding gas can have a serious detrimental effect on tung-

sten life. The use of mixed gases such as 95%Ar/5%H2 or

75%He/25%Ar, may also limit tungsten life. Similarly, oxi-

dation or other surface contaminants on the metal can

adversely affect tungsten wear. The rule of thumb is to

change the tungsten if the weld quality deteriorates. For

high-purity tube welds, tungsten is often changed after a

set number of welds for that particular application.

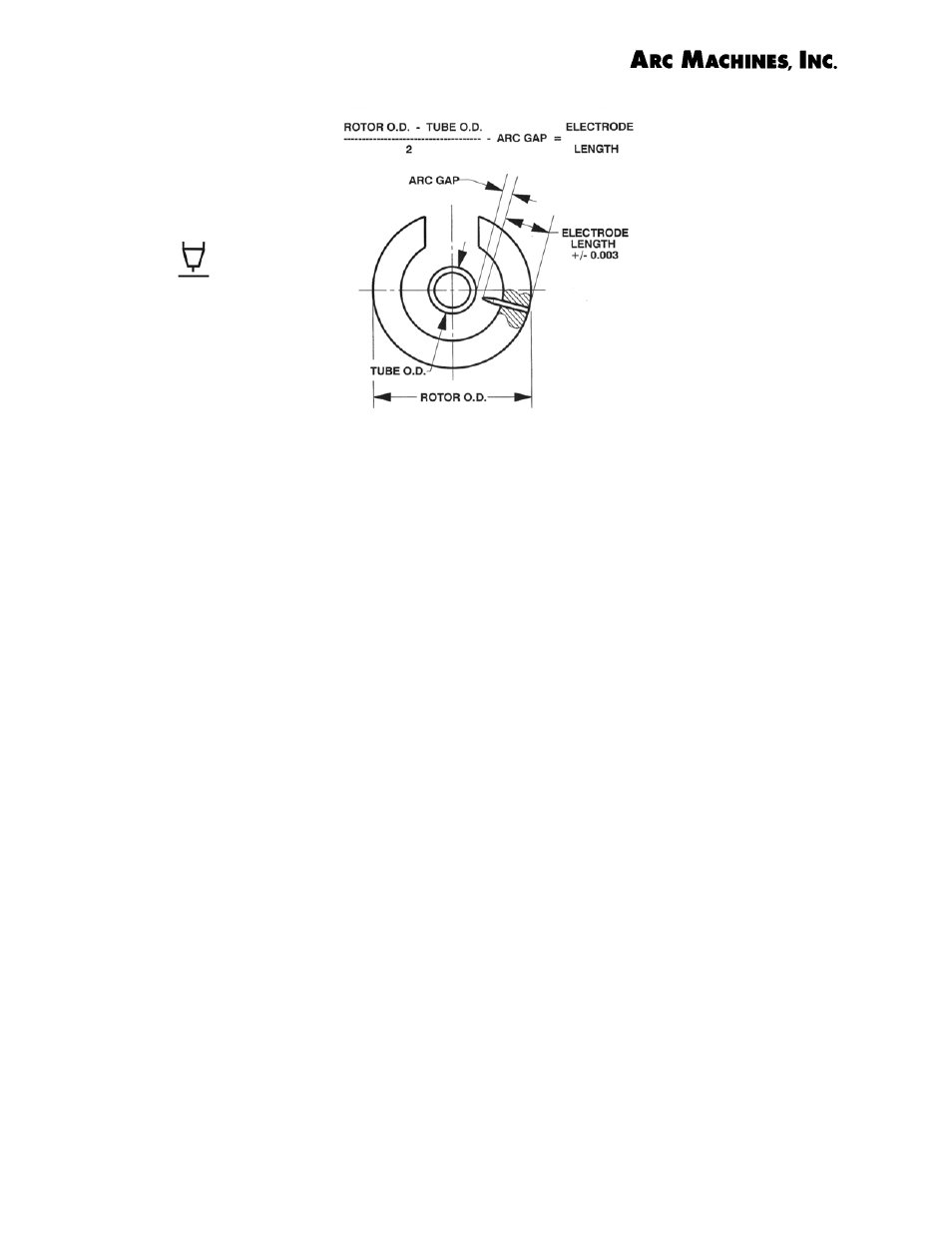

Formula for calculation

of Tungsten Length

and diagram of relation-

ship of Tungsten Length

to Rotor Diameter and

Arc Gap.