Programming single entry weld parameters – Arc Machines 307 User Manual

Page 107

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Document No. 740096 Chapter 9. Page 3.

Rev. A

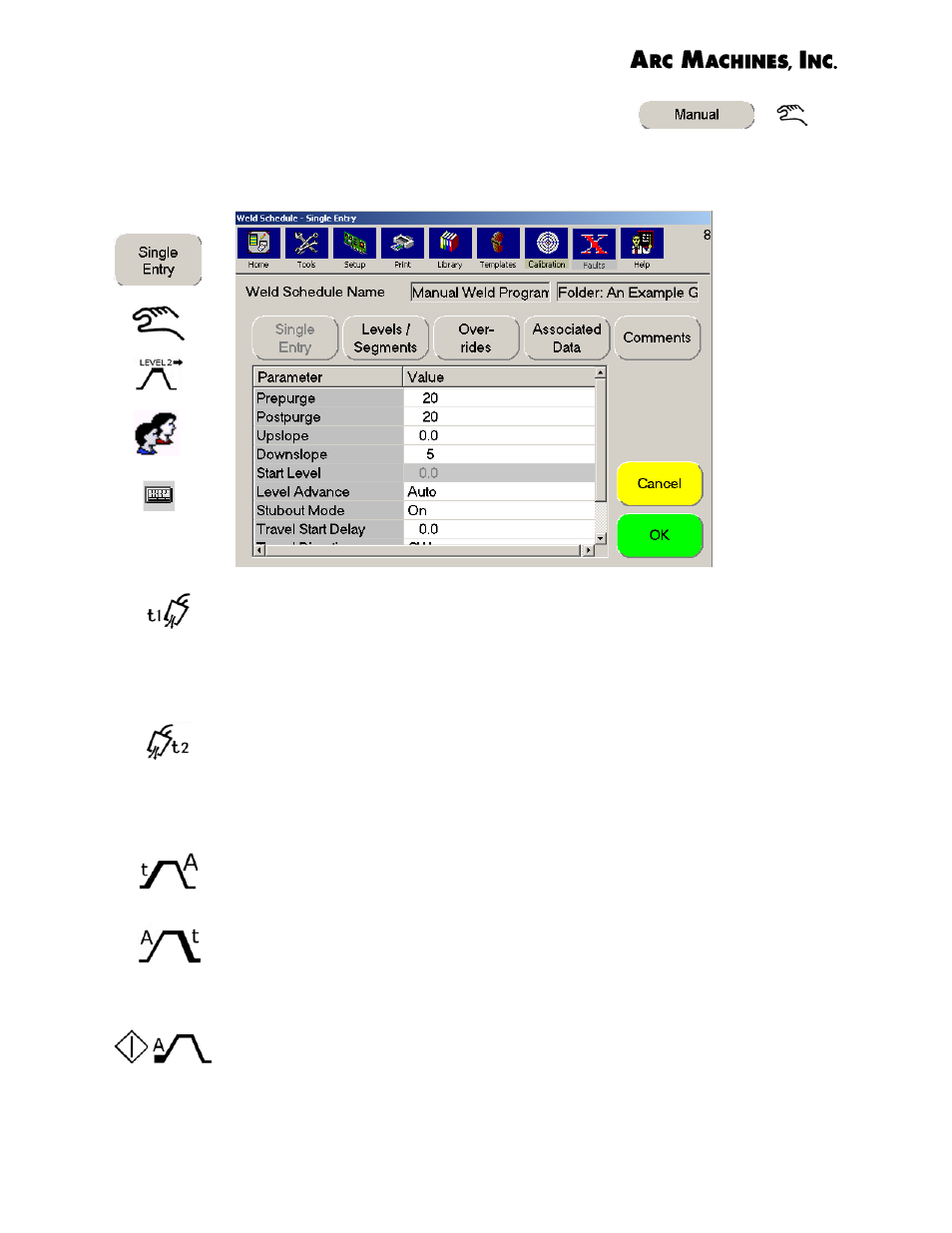

Programming Single Entry Weld Parameters

When Manual is selected, default or zero values for weld parameters will be

shown. The programmer must select each parameter and enter a value from

the keyboard.

Prepurge: The Prepurge time will default to the minimum rec-

ommended setting for the specific weld head selected. Using

longer prepurge times will result in cleaner welds and longer elec-

trode life. See Chapter 16 for recommended minimum prepurge

times.

Postpurge: The Postpurge time will default to the minimum

recommended setting for the specific weld head selected. Using

longer postpurge times will result in cleaner welds and longer

electrode life. See Chapter 16 for recommended minimum post-

purge times.

Upslope: The Upslope time is typically set for 0.0 for autogenous

welds. Upslope may be programmed for wire feed applications.

Downslope: Downslope time must be sufficient to prevent a cra-

ter or crack, no less than 2 seconds, typically from 4 to 15 sec.

Longer times are recommended for larger diameters. Enter 5

seconds for the 0.500 O.D. tube.

Start Level: - Start Level is the amperage at which the 307 initi-

ates the arc if upslope is used. When upslope is set to zero, the

start level current is equal to Level 1 primary amps.