I.d. (back) purge – Arc Machines 307 User Manual

Page 158

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Document No. 740096

Chapter 16. Page 5.

Rev. A

I.D. (Back) Purge

The purge supplied to the inside diameter of the weld joint must be meas-

ured and controlled. Separate flow indicators are recommended for the

shield and purge gas

lines. Prepurge and

postpurge times for

the I.D. purge are

not controlled by the

power supply but the

purge is turned on

before beginning the

weld sequence and

turned off after the

end of postpurge by

the welding operator.

These times must be

adequate to prevent

excessive discolora-

tion of the weld I.D.

Insufficient purge

gas flow will result in

discoloration of the

weld and/or HAZ of

the I.D. weld. A high

I.D. purge flow rate

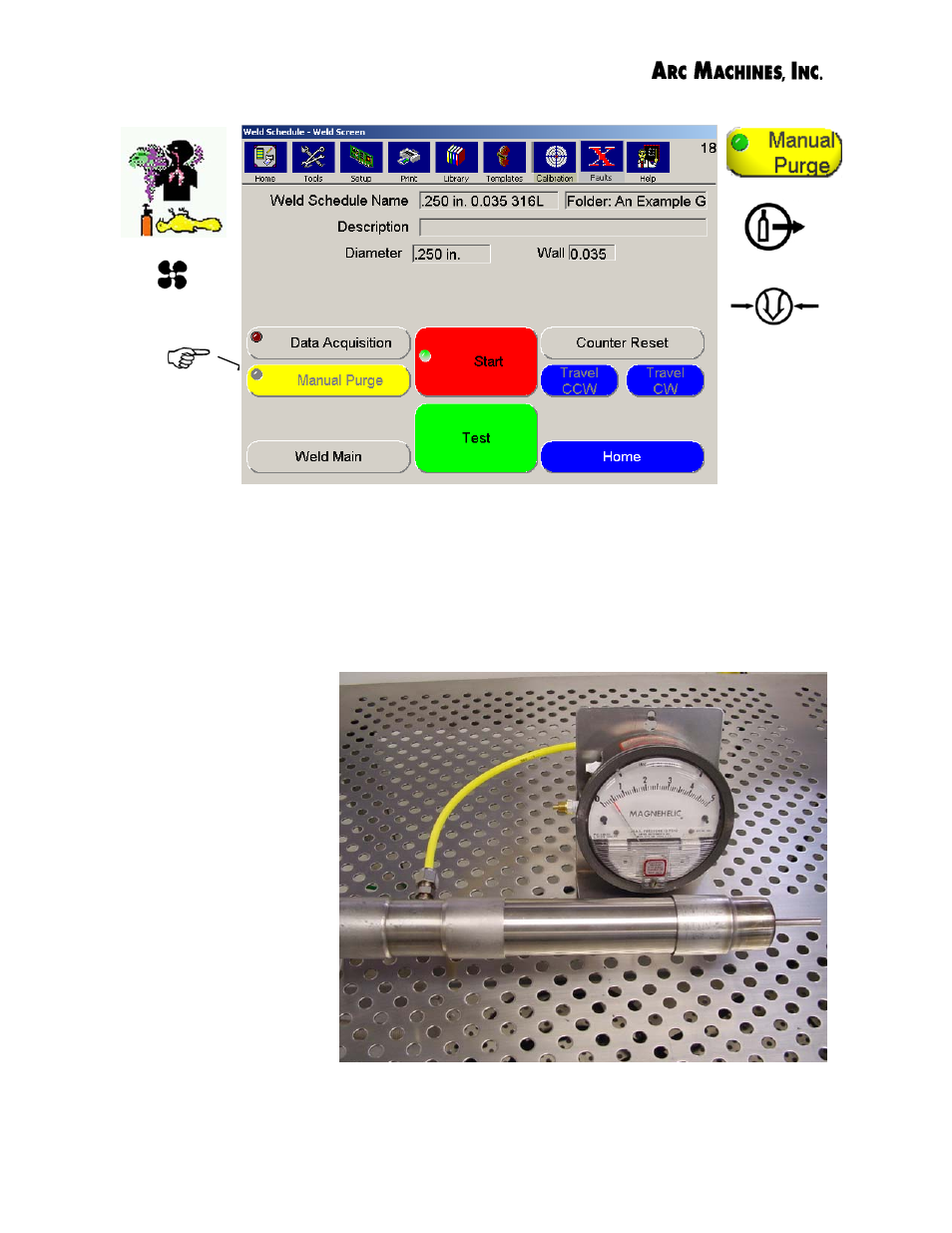

A pressure gauge inserted at the weld joint that measures gas

pressure in inches of water column is often used in high-purity

process piping applications to assure that the I.D. purge pres-

sure is correct before beginning to weld. The gauge is removed

for welding.

Prior to welding the flow rate to the weld head (O.D.) is set

by touching the Manual Purge button on the Weld Schedule -

Weld Screen screen and setting the flow from the regulator/

flowmeter.