Weld defect troubleshooting chart – Arc Machines 307 User Manual

Page 133

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Document No. 740096

Chapter 12. Page 4.

Rev. A

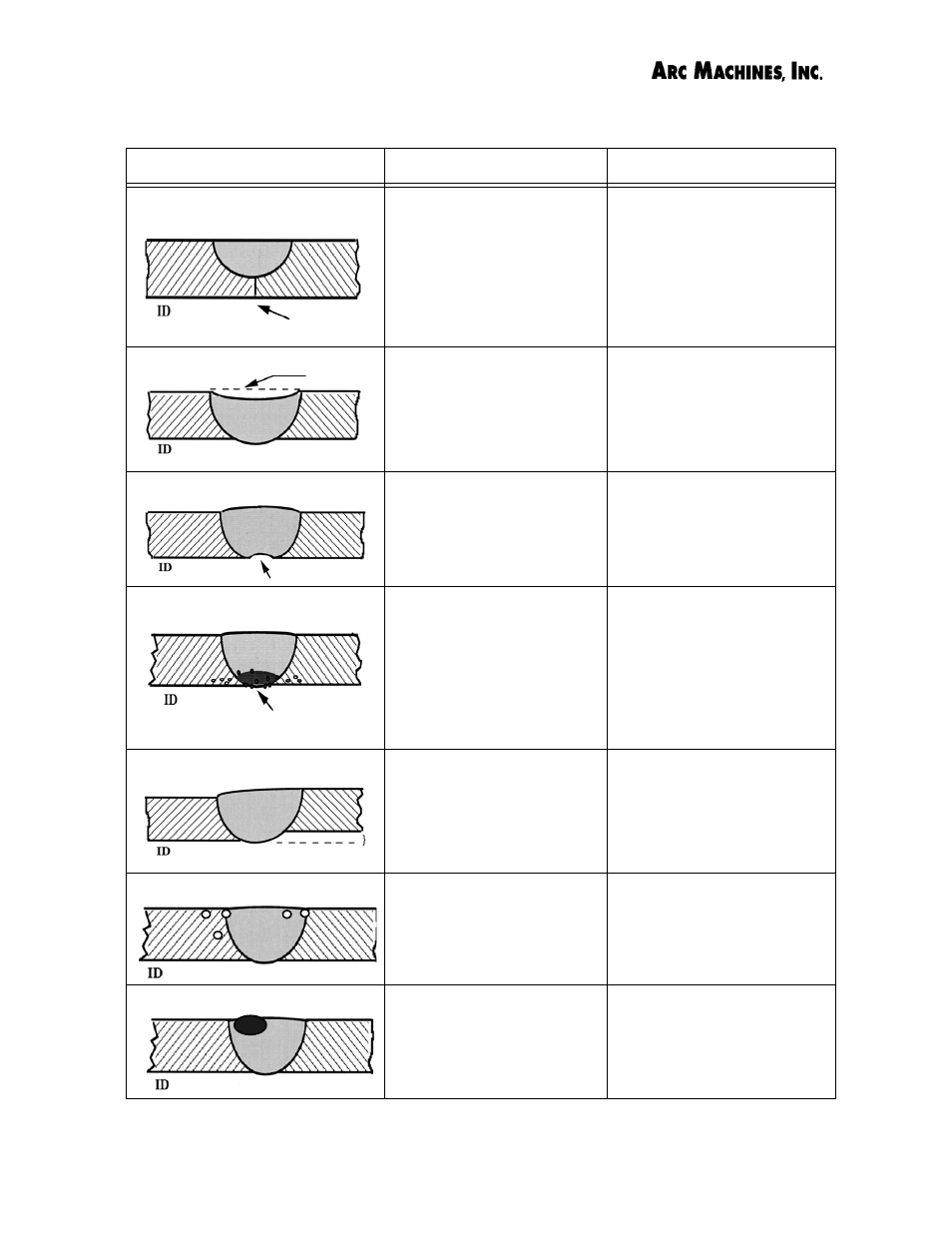

Weld Problem

Probable cause(s)

Remedy

Lack of penetration to the ID

1) Insufficient amperage

2) tungsten offset

3) different heat number

4) sulfur mismatch

5) variable wall thickness

6) Fluctuations in power

source

1) Increase amps for

affected level(s)

2) verify electrode center-

ing

3) verify heat number

4) make two passes

5) verify wall thickness -

6) Use dedicated circuit

OD Concavity

1) Too much amperage

2) Gravity (heavy-walled

material)

3) Very low sulfur content

1) Reduce amperage for

affected level(s)

2) Reduce heat for that

level 3) Increase ID purge

pressure (thin-walled tub-

ing)

ID Concavity

1) Excessive ID purge

pressure

2) Reduce ID purge flow-

rate or increase size of exit

orifice (restrictor)

Discoloration of ID (Oxidation)

1) Excessive oxygen and/

or moisture in ID purge

gas

2) Moisture and/or oxy-

gen in or on tubing -

chemical residue from EP

3) Leak in purging set-up

4) Pinched gas hose

1) Verify gas purity -

check condition of purifier

2) Clean and dry tubing -

heating may be necessary

3) Check purge system for

leaks - replace fittings

4) Check gas hose

Misalignment

1) Dimensional tolerances

- out-of-round

2) Wall thickness mis-

match

3) Worn out TCIs

4) Poor workmanship

1) Verify components

meet specified tolerances

2) Check wall thicknesses

3) Replace TCIs

4) Tack weld components

and/or use alignment tools

Porosity

1) Moisture in purge gas

2) Moisture or dirt on

weld components

1) Purify gas

2) Clean and dry weld

components

Excessive slagging

1) Impurities in base

material especially oxides

of aluminum, calcium,

silicon

1) Increase amperage

2) Vary pulse times

3) Try argon/hydrogen

mix

4) Change material

Weld Defect Troubleshooting Chart