Types of defects that are disallowed, Visual weld criteria – Arc Machines 307 User Manual

Page 163

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Document No. 740096

Chapter 17. Page 2.

Rev. A

For certification of orbital welds to ASME Sect. IX and B31.3, there must be

a Q.A. manual and a Q.A. program in effect and a set of generalized weld

standards which may reference any other standard, such as SEMI or ASME

BPE-2002. Qualified weld procedures must be developed, preferably on the

actual heats of material being installed. The orbital weld schedule which lists

weld parameters such as welding currents, pulse times, rotational speed,

and times is frequently used as part of the PQR.

To verify the structural integrity of welds, tube samples are welded, submit-

ted to a testing facility, and subjected to bend tests to assure that the weld

is ductile, and tensile tests to show that the weld meets the minimal tensile

strength of the base material. The weldment typically breaks in the HAZ, but

if it should break in the weld but still meet the minimal tensile strength of

the material, it is acceptable. ((No grinding of autogenous (fusion) orbital

welds in preparation of the test specimens is required.))

Documentation of welding procedures includes a WPS (Weld Procedure

Specification, form QW-482) and PQR (Procedure Qualification Record, form

QW-483). If the welder performing the welds is to be qualified as well, a

WOPQR (Welding Operator Performance Qualification Record, form QW-

484B) must be also be filled out.

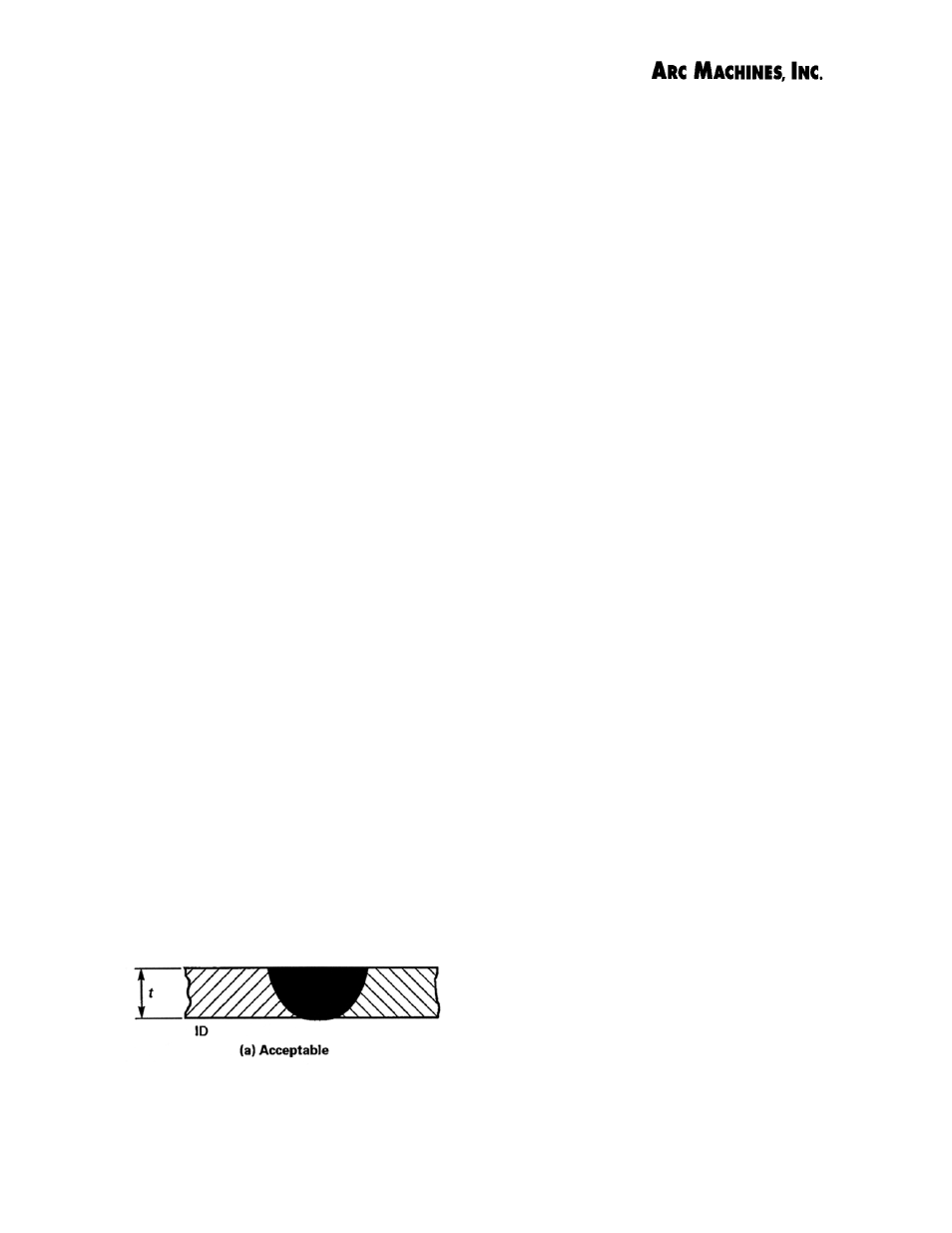

Types of Defects that are Disallowed

Weld qualification to ASME Sect. IX and B31.3 does not permit discontinui-

ties such as cracks, porosity, lack of penetration of the weld bead to the ID,

undercut or excessive OD reinforcement, which would affect the structural

integrity of the weldments.

Visual Weld Criteria

Weld bead smoothness. Standards for the semiconductor and bioprocess

industries are concerned with internal weld bead smoothness, surface fin-

ish, and cleanliness of the product contact surfaces. Smoothness is impor-

tant for semiconductor applications because a smoother surface takes less

time to dry down and to get the particle count down to specified levels. Weld

surfaces in bioprocessing and food and dairy equipment must be smooth in

order to discourage microbial growth and contamination of the product.

Full penetration welds. Virtually all

applications of orbital fusion welding in-

sist upon welds in which the weld bead

is fully penetrated around the entire ID

weld joint circumference. ASME BPE-

2002 requires that all welds be fully-