Arc Machines 307 User Manual

Page 132

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Document No. 740096

Chapter 12. Page 3.

Rev.A

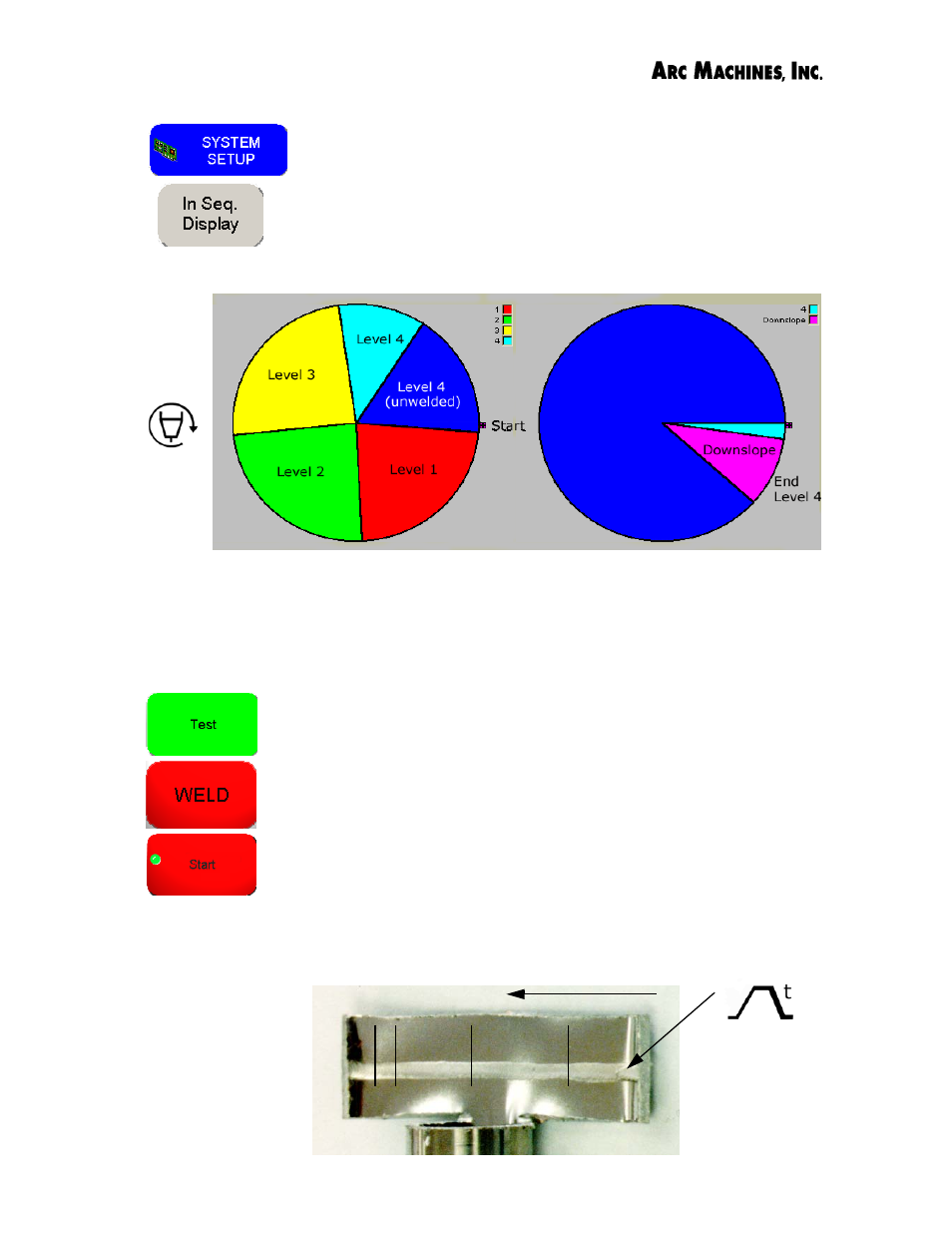

The Radial Graph (pie chart) feature of the Model 307 can

be used to detemine the location of level changes on the

weld circumference. To display the pie chart during test

runs or welds, touch the System Setup button on the 307

Opening Screen and then select the gray In-Sequence

Display button, Select Radial Graph.

Make a Trial Weld. With the power supply properly in-

stalled, and weld head calibrated, install weld coupons in weld

head and connect an appropriate purge. From the Weld Sched-

ule - Weld Screen with the green Test button, touch the green

button to show the red Weld button then touch Sequence Start.

Examine each section of the Trial Weld and adjust parameters

in each level. Examine weld for discoloration, misalignment,

cracks and porosity. Make changes in weld procedure to

achieve repeatable consistent high-quality welds.

Trial Weld - determine the direction of electrode travel, the location of level

changes and make modifications as needed. Note- the tip of the Downslope

points in the direction of electrode travel.

Radial Graphs generated by the Model 307 during the welding sequence show

position of electrode on the tube during the weld and at the end of each level.

Left: electrode in the middle of Level 4. Right: electrode near the end of

Downslope. Start position was 3 o’clock.