Programmable variables, Programmable variables: single entry – Arc Machines 307 User Manual

Page 52

Arc Machines, Inc. Model 307 Orbital Tube Welder Training

Document No. 740096

Chapter 5. Page 3.

Rev. A

Programmable Variables

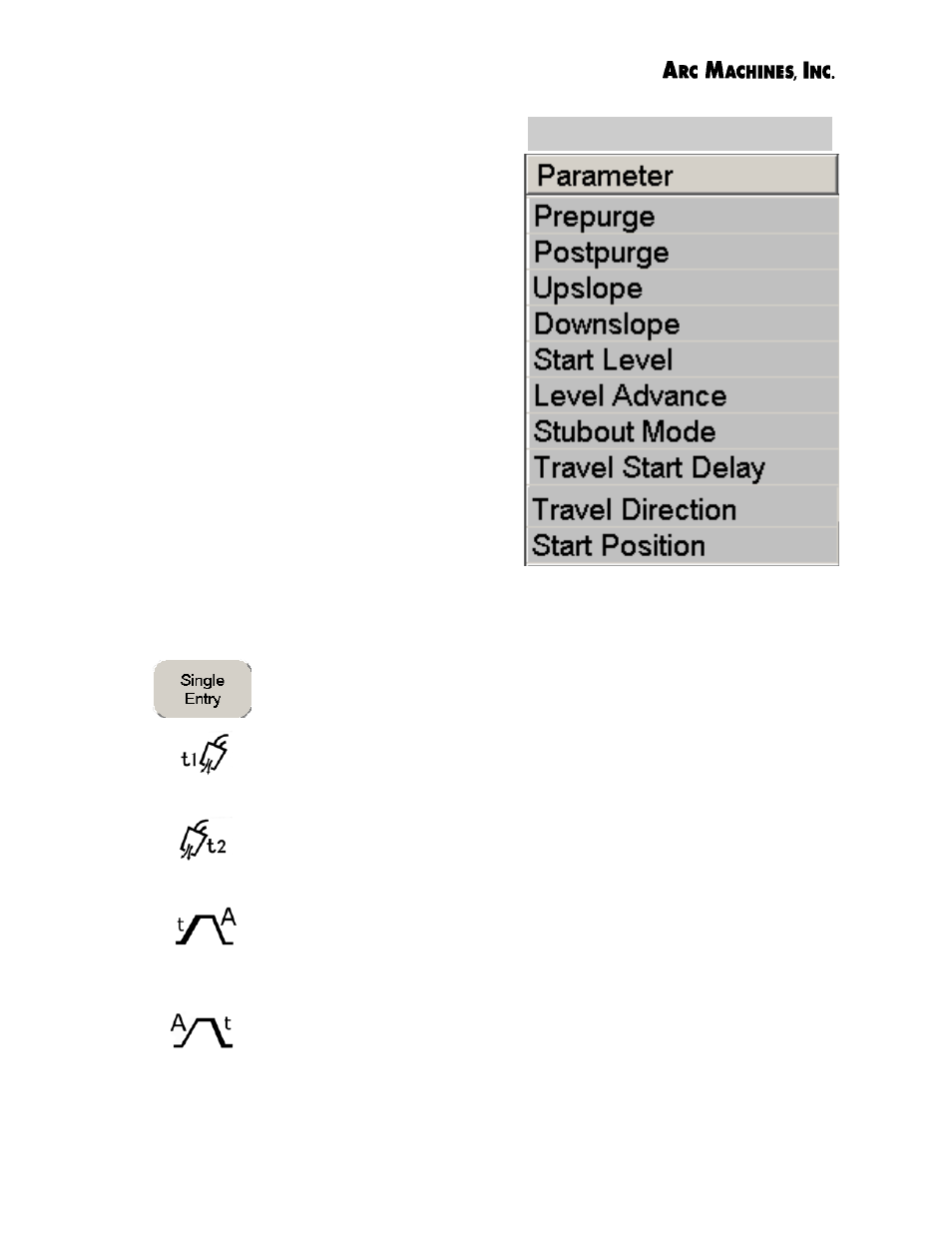

The programmable variables which

are controlled by the Power Supply are

divided into two categories on the

Model 307 and are shown on different

screens. Single Entry parameters are

those that are entered only once and

remain the same for all levels of a

schedule. Level/Segment parame-

ters may be changed from level-to-

level.

Non-programmable variables are

not controlled by the power supply but

are an essential part of the program

and must be controlled as well. Data,

such as electrode length and purge

flow rates may be entered from the

Associated Data screens entered

from the Weld Schedule - Main Screen.

This information will not be acted on

by the power supply but becomes a

part of the weld record for documenta-

tion purposes.

PROGRAMMABLE VARIABLES: Single Entry

Prepurge time: Inert gas must be supplied to the weld

head for the entire weld sequence to minimize oxidation

of the weld O.D. The Prepurge time is the amount of

time the shield gas flows to the weld head between the

start of sequence and arc initiation.

Postpurge is the amount of time the gas is allowed to

flow after the arc is extinguished. See chart for recom-

mended flow rates and purge times for the different AMI

weld heads.

Upslope: Upslope is the time programmed for the current

to reach the full value after striking an arc. It is normally

set to zero (0.0 sec.) for autogenous welds.

Downslope: is the time set for the arc to extinguish after

the end of the last programmed level. Typically this

should be from 4 to 15 seconds depending on tube diame-

ter.

Single Entry Parameters